JIAOTONG UNIVERSITY 096 Supply Chain Management Lecture 7-2 Integrated Planning Instructor(s) Prof.Jianjun Gao Department of Automation School of Electronic Information and Electrical Engineering SEIEE AU406

Supply Chain Management Instructor(s) SEIEE AU406 + - Integrated Planning Prof. Jianjun Gao Department of Automation School of Electronic Information and Electrical Engineering Lecture 7-2

Outline Role of aggregate planning in a supply chain The aggregate planning problem Aggregate planning strategies Managing Predictable Variability SEIEE AU406 8-2

+ - SEIEE AU406 8-2 Outline Role of aggregate planning in a supply chain The aggregate planning problem Aggregate planning strategies Managing Predictable Variability

Role of Aggregate Planning in a Supply Chain Capacity has a cost,lead times are greater than zero Aggregate planning: process by which a company determines levels of capacity,production,subcontracting,inventory, stockouts,and pricing over a specified time horizon ■ goal is to maximize profit time frame of 3 to 18 months how can a firm best use the facilities it has? SEIEE AU406 8-3

+ - SEIEE AU406 8-3 Role of Aggregate Planning in a Supply Chain Capacity has a cost, lead times are greater than zero Aggregate planning: process by which a company determines levels of capacity, production, subcontracting, inventory, stockouts, and pricing over a specified time horizon goal is to maximize profit time frame of 3 to 18 months how can a firm best use the facilities it has?

Role of Aggregate Planning in a Supply Chain Specify operational parameters over the time horizon: production rate workforce overtime machine capacity level subcontracting backlog inventory on hand All supply chain stages should work together on an aggregate plan that will optimize supply chain performance SEIEE AU406 8-4

+ - SEIEE AU406 8-4 Role of Aggregate Planning in a Supply Chain Specify operational parameters over the time horizon: production rate workforce overtime machine capacity level subcontracting backlog inventory on hand All supply chain stages should work together on an aggregate plan that will optimize supply chain performance

The Aggregate Planning Problem Given the demand forecast for each period in the planning horizon,determine the production level, inventory level,and the capacity level for each period that maximizes the firm's(supply chain's) profit over the planning horizon Specify the planning horizon (typically 3-18 months) Specify the duration of each period Specify key information required to develop an aggregate plan SEIEE AU406 8-5

+ - SEIEE AU406 8-5 The Aggregate Planning Problem Given the demand forecast for each period in the planning horizon, determine the production level, inventory level, and the capacity level for each period that maximizes the firm’s (supply chain’s) profit over the planning horizon Specify the planning horizon (typically 3-18 months) Specify the duration of each period Specify key information required to develop an aggregate plan

Information Needed for an Aggregate Plan Demand forecast in each period ■Production costs labor costs,regular time($/hr)and overtime ($/hr) ■ subcontracting costs($/hr or $/unit) cost of changing capacity:hiring or layoff($/worker)and cost of adding or reducing machine capacity ($/machine) a Labor/machine hours required per unit Inventory holding cost ($/unit/period) Stockout or backlog cost ($/unit/period) Constraints:limits on overtime,layoffs,capital available, stockouts and backlogs SEIEE AU406 8-6

+ - SEIEE AU406 8-6 Information Needed for an Aggregate Plan Demand forecast in each period Production costs labor costs, regular time ($/hr) and overtime ($/hr) subcontracting costs ($/hr or $/unit) cost of changing capacity: hiring or layoff ($/worker) and cost of adding or reducing machine capacity ($/machine) Labor/machine hours required per unit Inventory holding cost ($/unit/period) Stockout or backlog cost ($/unit/period) Constraints: limits on overtime, layoffs, capital available, stockouts and backlogs

Outputs of Aggregate Plan Production quantity from regular time,overtime,and subcontracted time:used to determine number of workers and supplier purchase levels Inventory held:used to determine how much warehouse space and working capital is needed Backlog/stockout quantity:used to determine what customer service levels will be Machine capacity increase/decrease:used to determine if new production equipment needs to be purchased A poor aggregate plan can result in lost sales,lost profits, excess inventory,or excess capacity SEIEE AU406 8-7

+ - SEIEE AU406 8-7 Outputs of Aggregate Plan Production quantity from regular time, overtime, and subcontracted time: used to determine number of workers and supplier purchase levels Inventory held: used to determine how much warehouse space and working capital is needed Backlog/stockout quantity: used to determine what customer service levels will be Machine capacity increase/decrease: used to determine if new production equipment needs to be purchased A poor aggregate plan can result in lost sales, lost profits, excess inventory, or excess capacity

Aggregate Planning Strategies Trade-off between capacity,inventory, backlog/lost sales Chase strategy -using capacity as the lever Time flexibility from workforce or capacity strategy -using utilization as the lever Level strategy -using inventory as the lever Mixed strategy-a combination of one or more of the first three strategies SEIEE AU406 8-8

+ - SEIEE AU406 8-8 Aggregate Planning Strategies Trade-off between capacity, inventory, backlog/lost sales Chase strategy – using capacity as the lever Time flexibility from workforce or capacity strategy – using utilization as the lever Level strategy – using inventory as the lever Mixed strategy – a combination of one or more of the first three strategies

Example:Red Tomato Red Tomato Tools,a small manufacturer of gardening equipment with manufacturing facilities in Mexico. Red Tomato's products are sold through retailers in the United States. Red Tomato's operations consist of the assembly of purchased parts into a multipurpose gardening tool. Because of the limited equipment and space required for its assembly operations,Red Tomato's capacity is determined mainly by the size of its workforce. SEIEE AU406 8-9

+ - SEIEE AU406 Example: Red Tomato Red Tomato Tools, a small manufacturer of gardening equipment with manufacturing facilities in Mexico. Red Tomato’s products are sold through retailers in the United States. Red Tomato’s operations consist of the assembly of purchased parts into a multipurpose gardening tool. Because of the limited equipment and space required for its assembly operations, Red Tomato’s capacity is determined mainly by the size of its workforce. 8-9

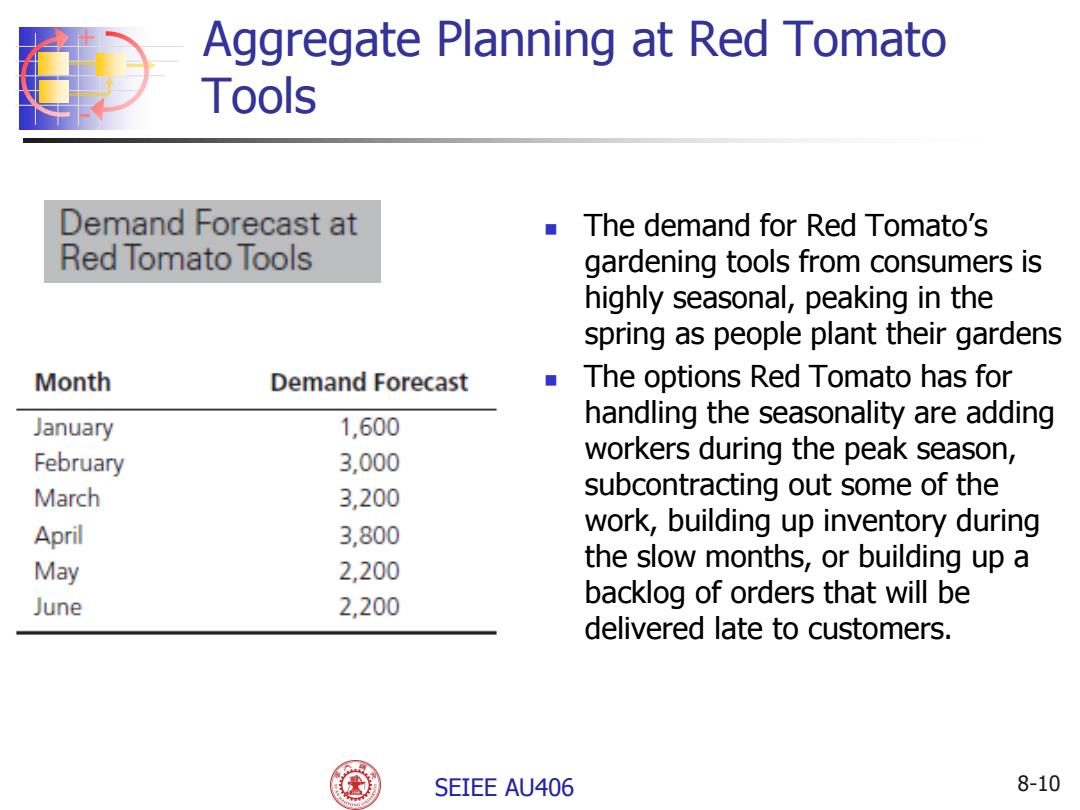

Aggregate Planning at Red Tomato Tools Demand Forecast at The demand for Red Tomato's Red Tomato Tools gardening tools from consumers is highly seasonal,peaking in the spring as people plant their gardens Month Demand Forecast ■ The options Red Tomato has for January 1600 handling the seasonality are adding February 3.000 workers during the peak season, March 3,200 subcontracting out some of the April 3,800 work,building up inventory during May 2,200 the slow months,or building up a June 2,200 backlog of orders that will be delivered late to customers. SEIEE AU406 8-10

+ - SEIEE AU406 8-10 Aggregate Planning at Red Tomato Tools The demand for Red Tomato’s gardening tools from consumers is highly seasonal, peaking in the spring as people plant their gardens The options Red Tomato has for handling the seasonality are adding workers during the peak season, subcontracting out some of the work, building up inventory during the slow months, or building up a backlog of orders that will be delivered late to customers