Vibration monitoring

Vibration monitoring

Outline of this part Vibration monitoring development Condition monitoring basic concept Vibration monitoring details onsite vibration monitoring sensors vibration monitoring example vibration monitoring process

Outline of this part • Vibration monitoring development • Condition monitoring basic concept • Vibration monitoring details onsite vibration monitoring sensors vibration monitoring example vibration monitoring process

Brief history Respect experienced person always!!l Traditionally Screw driver against ear. Surprisingly reliable-depends on skill and experience of individual. Develop instruments Initially simple vibration meters-read rms velocity. Later integration of accelerometer signal introduced rms estimates of acceleration,velocity,displacement Peak value crest factor. Experienced operators still identify incipient failures long before detected by basic meters

Brief history Respect experienced person always!!!

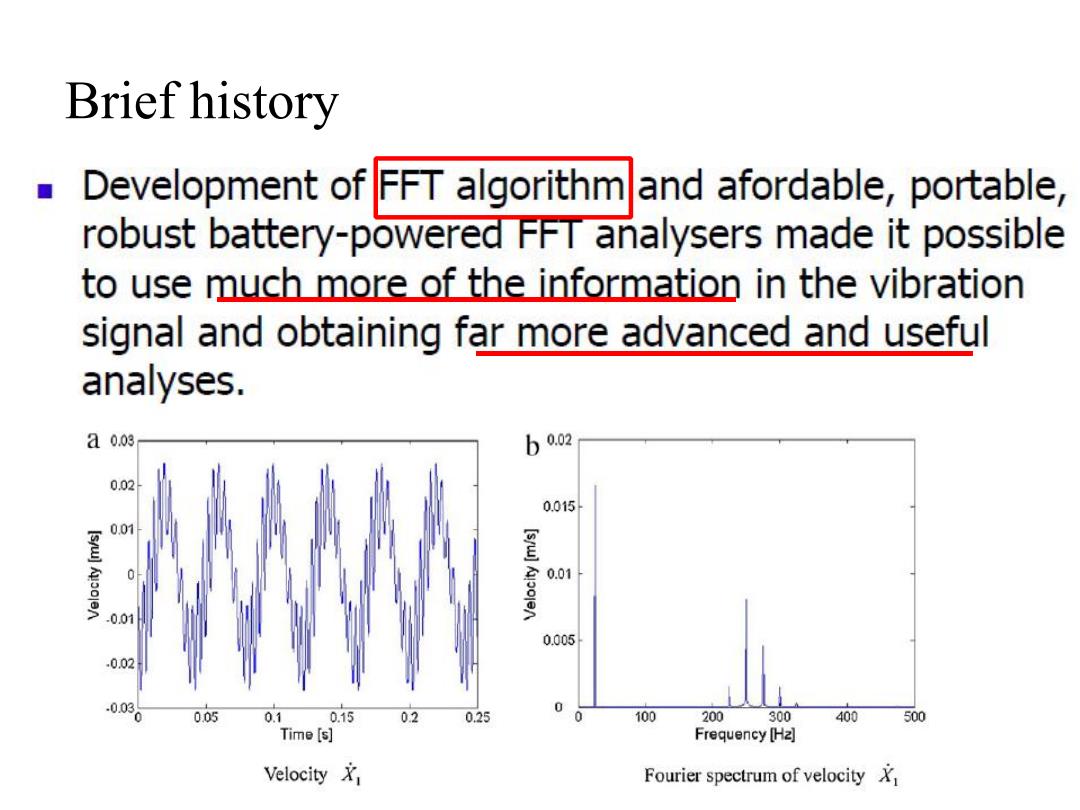

Brief history Development of FFT algorithm and afordable,portable, robust battery-powered FFT analysers made it possible to use much more of the information in the vibration signal and obtaining far more advanced and useful analyses. a0.03 bo.02 0.02 0.015 0.01 0.01 0.01 0.005 .0.02 .0.03 0 005 0.1 0.15 02 0.25 100 200 300 400 500 Time [s] Frequency [H2] Velocity Fourier spectrum of velocity

Brief history

Brief history Condition based vibration monitoring established as reliable and cost effective technique for monitoring and diagnosis of machine faults before irreversible damage occur 9情得

Brief history

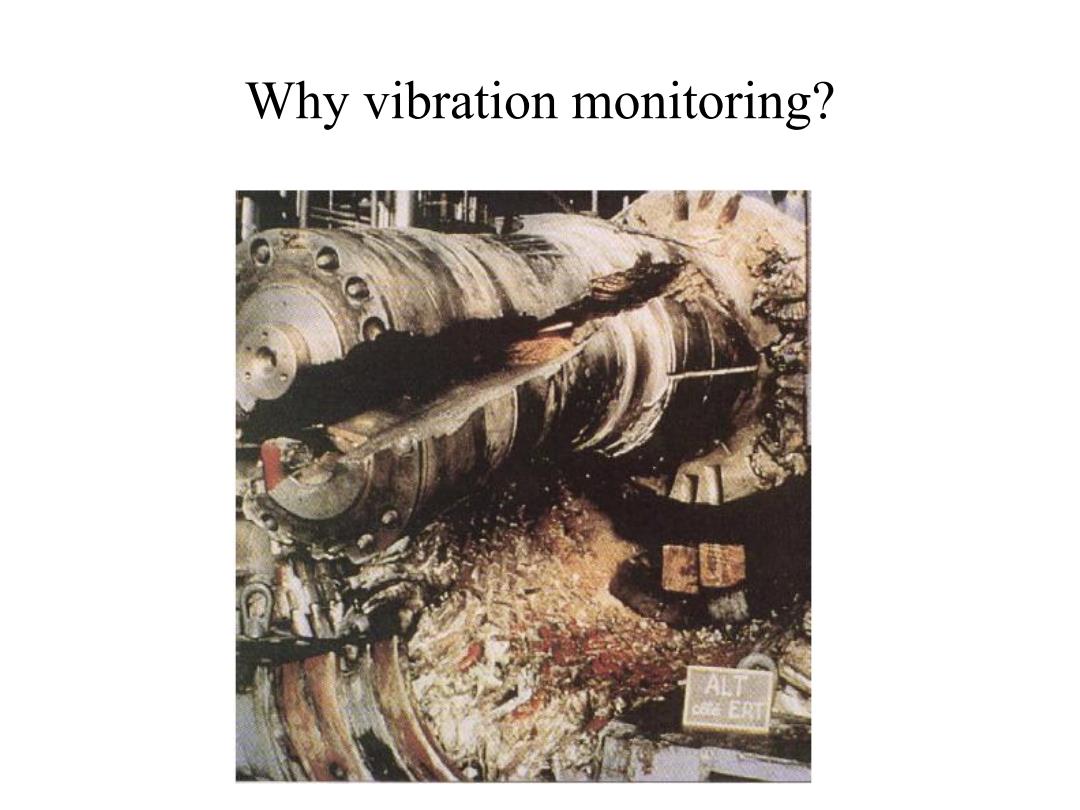

Condition monitoring entails continuous or periodic determination of the condition of a plant or machine component during operation or of a structural component while in service.This is in contrast to scheduled maintenance. Reduced maintenance cost. Increased running time between shut-downs. Increased availability of machinery.Avoids catastrophic failures. Reduced spare part stock holdings and improved safety. Identification of nature and origin of fault. Noise and vibration analysis one of several condition monitoring techniques(temperature,current and voltage,metallurgical,oil- analysis). Vibration as a diagnostic tool most widely applied

Why vibration monitoring? ALT ct ERT

Why vibration monitoring?

Onsite vibration monitoring AAAA

Onsite vibration monitoring

Vibration monitoring equipment Monitoring sometimes done under very difficult circumstances

Vibration monitoring equipment

Sensors ■PCB Accelerometers CHARGE ACCEE 352C41 D化C昌 PC會 SPCB

Sensors