附件24.2 Chapter 1 Introduction to Hydraulic and Pneumatic Transmission,2 hours.(《液压与气压传动》概论,2学时) Knowledge points:the basic operating principle,buildup of the system,the characters of hydraulic and pneumatic application and development trend. (知识点:液汽压传动与控制的基本工作原理,系统组成,液气压传动的特点及应用和发展趋势) Emphasis:the basic operating principle and buildup of the system in hydraulic and pneumatic transmission (重点:液/气压传动与控制的基本工作原理,系统组成) (难点:实现液压传动两个重要特征的理解) l.1 Study on Hydraulic and Pneumatic Transmission(液压与气压传动的研究内容) 国 Chapter I Introduction to Hydranlie and 7c7I77c17IS7S3107n 1.1 Study on Hydraulic and Pneumatic Transmission The main study of this course: (1)Operating principle.sub-circuit and the hydraulic system (2)Physical performances and static/dynamic characters of flui (3)Designs of the Hydraulic and pneumatic system L.2 Operating Principles of Hydraulic Transmission(液压传动的工作原理) Chapter ntrodiction to Hydranlie and Pnematic Transmission 12 Onerating Princinles of Hydraulic Transmission Pascal's law:pressure eve undiminished in all directions and acts with equal force on all equal areas To pull up press dow igure.1-1 Operating principle of hydraulic jack 4

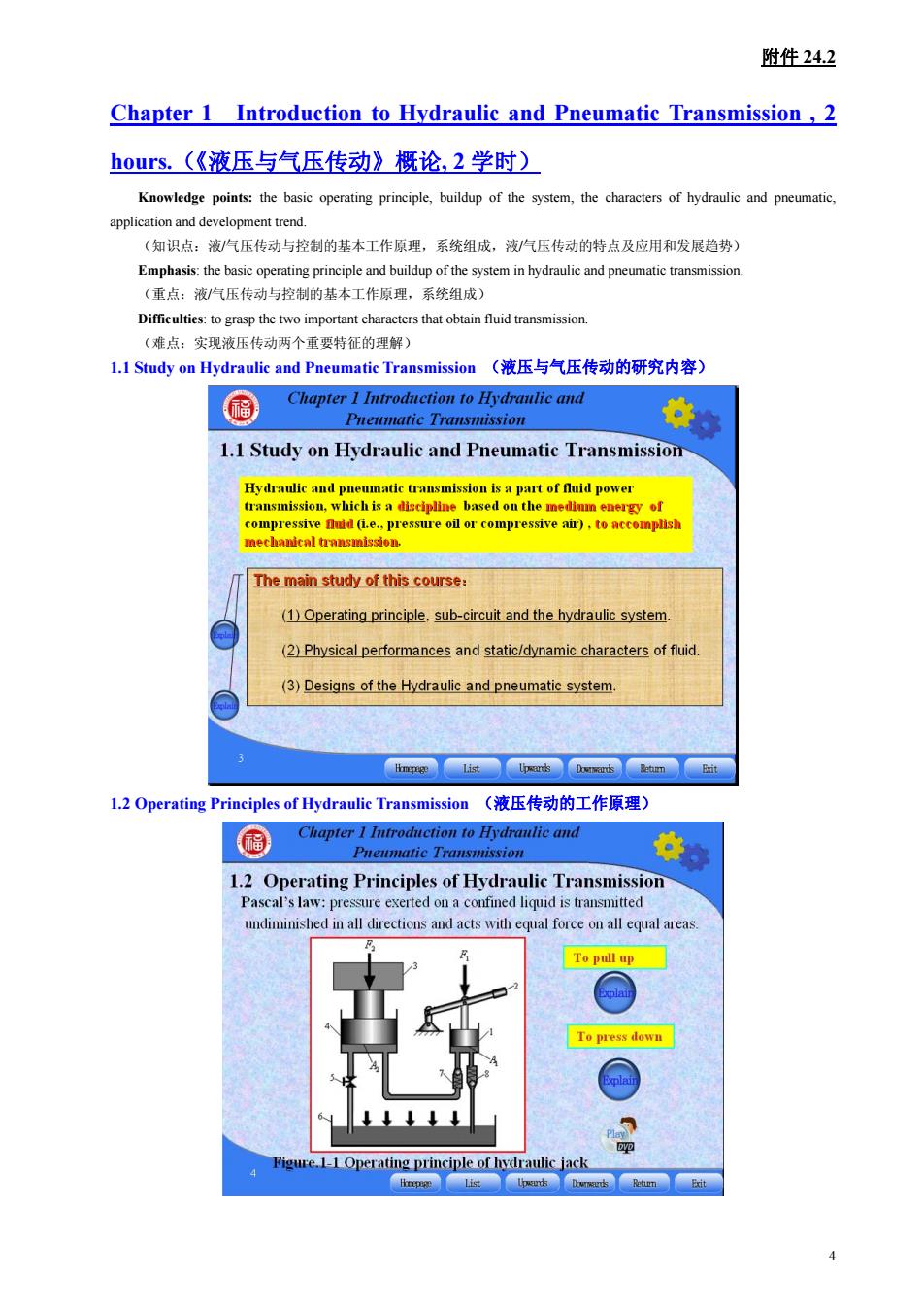

附件 24.2 Chapter 1 Introduction to Hydraulic and Pneumatic Transmission , 2 hours.(《液压与气压传动》概论, 2 学时) Knowledge points: the basic operating principle, buildup of the system, the characters of hydraulic and pneumatic, application and development trend. (知识点:液/气压传动与控制的基本工作原理,系统组成,液/气压传动的特点及应用和发展趋势) Emphasis: the basic operating principle and buildup of the system in hydraulic and pneumatic transmission. (重点:液/气压传动与控制的基本工作原理,系统组成) Difficulties: to grasp the two important characters that obtain fluid transmission. (难点:实现液压传动两个重要特征的理解) 1.1 Study on Hydraulic and Pneumatic Transmission (液压与气压传动的研究内容) 1.2 Operating Principles of Hydraulic Transmission (液压传动的工作原理) 4

附件242 Chapter I Introduction to Hydraulic and Pneumatic Transmission 1.Power transfer Let us take the hydraulic pressure in the actuator as p F Let's note the piston area of actuator as A.the A total thurnst on it as the thrust on the small piston of pump is F scalled the hydranli 5=p4=h4=4=() 4 is the piston area of pump. Thus We can get the first important character that the working pressure in a hydraulic system depends on the outside Chapter I Introduction to Hydraulie and Pnem When we neglect the compressibility,leaking and 2.Motion transfer deforn action,. The volume of displacement is equal to the volume drawn into and then: Lets note the piston moving distance in the SA-S,A2 (1-3) Divided by the moving time t on both sides on the above formula, we have: Where v,and v,are noted the average speed of lvdraulic pum and hydraulic actuator 1=vd=v42=9 边the pump and q is the oil the actuator. We can get the second impo tant law that the motion speed of piston in actuator depend on the inle fow rate,but is independent of the outside load. Hydranlic oil pressure and the flow rate are the two main parameters in the hydrauli Smn-mp l.3 Composition of Hydraulic Transmission System(液压传动系统的组成)

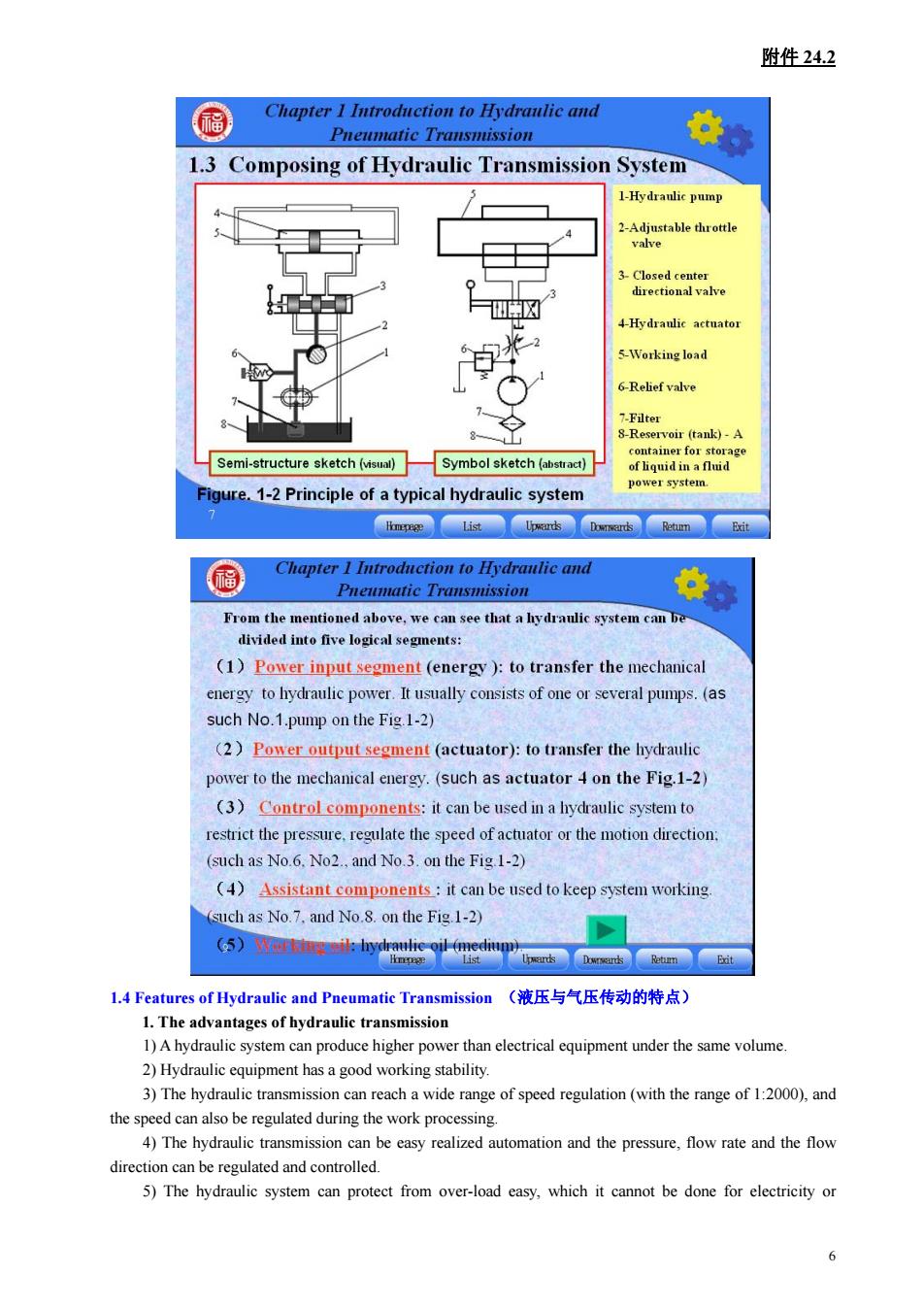

附件 24.2 1.3 Composition of Hydraulic Transmission System (液压传动系统的组成) 5

附件24.2 Chapter I Introduction to Hydranlic and Pneumatic Transmission 1.3 Composing of Hydraulic Transmission System 1-Hydraulic pump alve ☒ 4-Hydranlic actuator 5-Working load -Reliefvalve voir (tank)-A Semi-structure sketch (vs) Symbol sketch (ab) re.1-2 Principle of a typical hydraulic system ⑧ Chapter I Introduction to Hydraulie and Pneimatic Transmission Frem the mentioned above,we can see that ystem ca ivided into five logical segnents: (1)Power input segment (energy )to transfer the mechanical energy to hydraulic power.It usually consists of one or several pumps.(a such No.1.pump on the Fig.1-2) (2)Power ouput segment (actuator):to transfer the hydralic power to the mechanical energy.(such as actuator 4 on the Fig.1-2) (3)Control components:it can be used in a hydraulic system to restrict the pressure.regulate the speed of actuator or the motion direction. (such as No.6.No2.and No.3.on the Fig1-2) (4)Assistant components:it can be used to keep system working. (such as No.7.and No.8.on the Fig.1-2) 1.4 Features of Hydraulic and Pneumatic Transmission(液压与气压传动的特点) 1.The advantages of hydraulic transmission 1)A hydraulic system can produce higher power than electrical equipment under the same volume 2)Hydraulic equipment has a good working stability. 3)The hydraulic tra smission can reach a wide range of speed regulation(with the range of 1:000)and the speed can also be regulated during the work processing. 4)The hydraulic transmission can be easy realized automation and the pressure.flow rate and the flow direction can be regulated and controlled. 5)The hydraulic system can protect from over-load easy.which it cannot be done for electricity or 6

附件 24.2 1.4 Features of Hydraulic and Pneumatic Transmission (液压与气压传动的特点) 1. The advantages of hydraulic transmission 1) A hydraulic system can produce higher power than electrical equipment under the same volume. 2) Hydraulic equipment has a good working stability. 3) The hydraulic transmission can reach a wide range of speed regulation (with the range of 1:2000), and the speed can also be regulated during the work processing. 4) The hydraulic transmission can be easy realized automation and the pressure, flow rate and the flow direction can be regulated and controlled. 5) The hydraulic system can protect from over-load easy, which it cannot be done for electricity or 6

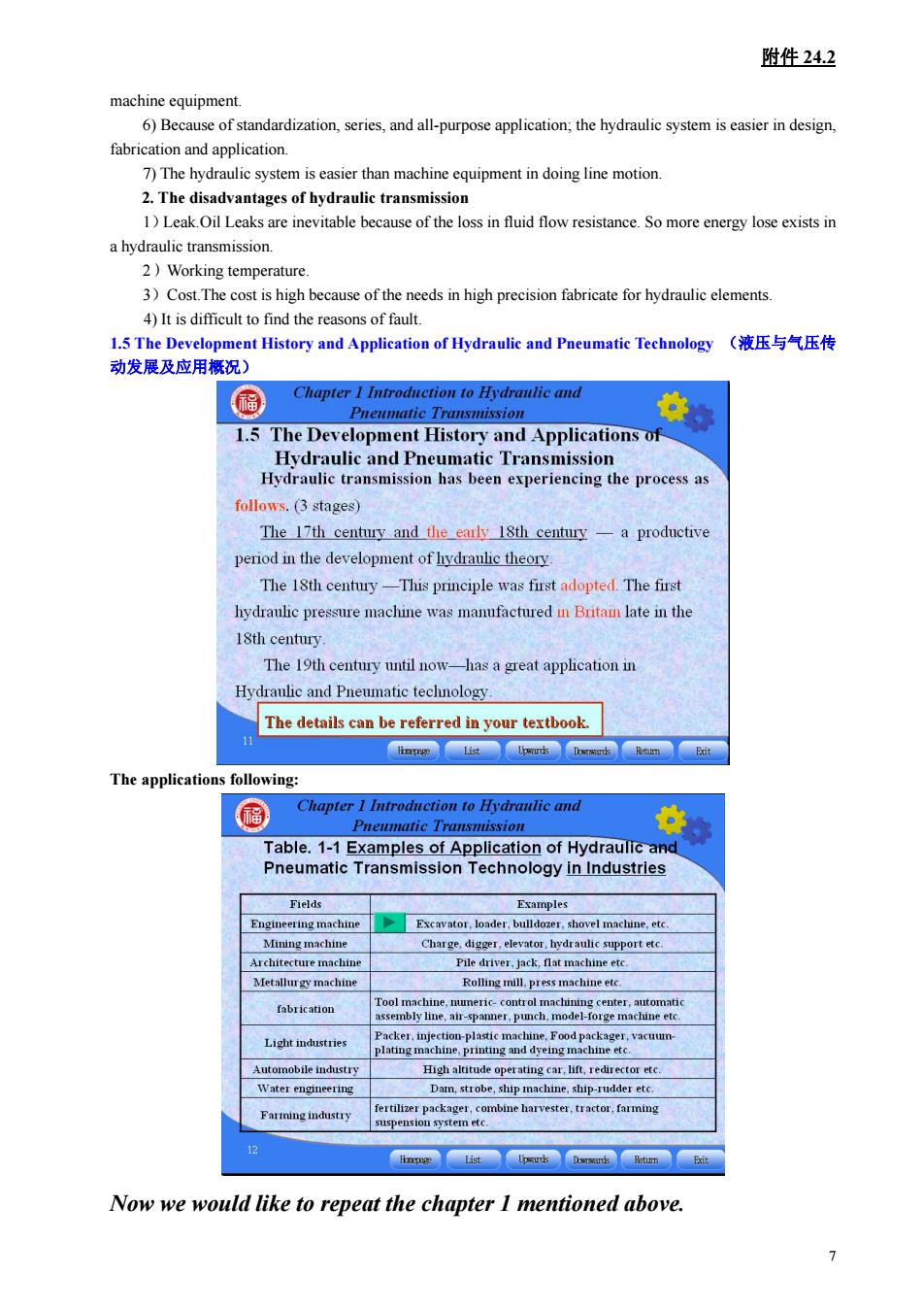

附件24.2 machine equipment 6)Because of standardization,eries,and all-purpose application,the hydraulic system iseasier in design. 7)The hydraulic system iseaser than machine equipment in dongine motion 2.The disadvantages of hydraulic transmission 1)Leak.Oil Leaks are inevitable because of the loss in fluid flow resistance.So more energy lose exists in a hydraulic transmission. 2 Working temperature 4)It is difficult to find the reasons of fault. l.5 The Development History and Application of Hydraulic and Pneumatic Technology(液压与气压传 动发展及应用概况) 国 1.5 The Development History and Applications of ission follows.(3 stages The 17th century and the early 18th century -a productive period in the development of hydraulic theory The 18th century-This principle was first adopted.The first hydraulic pressure machine was manufactured m Britain late in the The 19th century until now-has a great application in The details can be referred in your textbook. The applications following: 痛 Table.1-1 Examples of Application of Hydraulic and Pneumatic Transmission Technc ogy in Industries Charge,digger,elevator.support etc Architecture machi Pile driver,jack,flat machine ete tallur gy mac中 fabrkcation 3- Light industries od 中 Water iagtetniehanetH,uaa,amiae Now we would like to repeat the chapter I mentioned above

附件 24.2 machine equipment. 6) Because of standardization, series, and all-purpose application; the hydraulic system is easier in design, fabrication and application. 7) The hydraulic system is easier than machine equipment in doing line motion. 2. The disadvantages of hydraulic transmission 1)Leak.Oil Leaks are inevitable because of the loss in fluid flow resistance. So more energy lose exists in a hydraulic transmission. 2)Working temperature. 3)Cost.The cost is high because of the needs in high precision fabricate for hydraulic elements. 4) It is difficult to find the reasons of fault. 1.5 The Development History and Application of Hydraulic and Pneumatic Technology (液压与气压传 动发展及应用概况) The applications following: Now we would like to repeat the chapter 1 mentioned above. 7

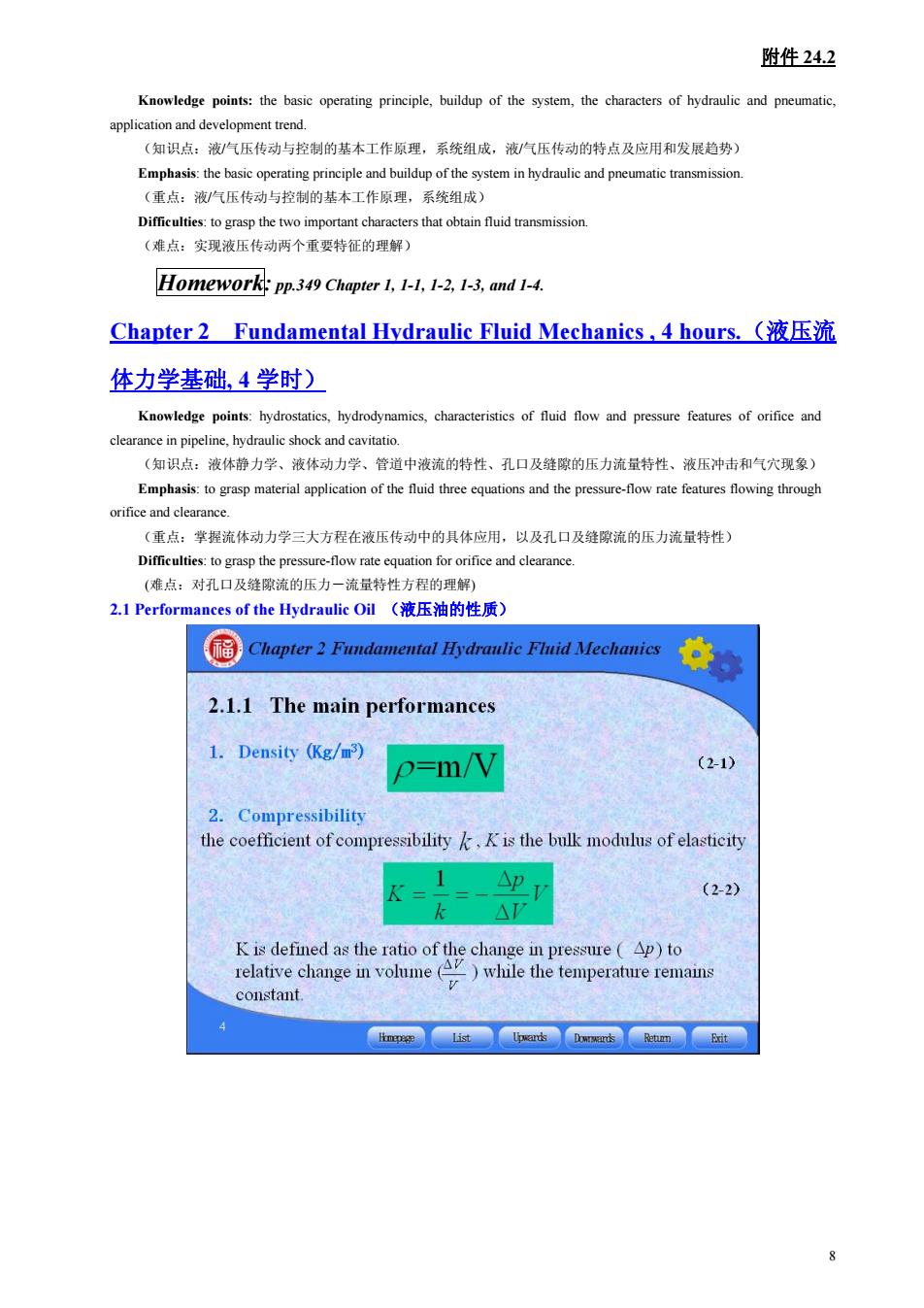

附件24.2 Knowledge points:the basic operating principle.buildup of the system,the characters of hydraulic and pneumatic. application and development trend. (知识点:液/气压传动与控制的基本工作原理,系统组成,液气压传动的特点及应用和发展趋势) Emphasis:the basico d buildup of the Difficulties:to grasp the two important characters that obtain fuid transmission. (雄点:实现液压传动两个重要特征的理解) Homework pp.349 Chapter 1,1-1,1-2,1-3,and 1-4 Chapter2 Fundamental Hydraulic Fluid Mechanics,4 hours.(液压流 体力学基础。4学时) Knowledge points:hydrostatics,hydrodynamics,characteristics of fuid flow and pressure features of rifice and shock and cavitat (知识点:液休静力学、液体动力学、管道中液流的特性、孔口及缝隙的压力流量特性、液压冲击和气穴现象) Emphasis:to grasp material application of the fluid three qutions and the pressure-flow rate features flowing through orifice and clearance. (重点,掌操流体动力学三大方得在液压传动中的具体应用。以及孔口及缝隙流的压力流量特性) 2.Performances of the Hydraulic Oil(液压油的性质) 2.1.1 The main performances 1.Density (Kg/m) P=m/V (210 2.Compressibilit时 the coefficient of compressibilityKis the bulk modulus of elasticity (2-2) △ K is defined as the ratio of the chan e m pressure(Ap)to relative change in volume )while the temperature remains constant

附件 24.2 Knowledge points: the basic operating principle, buildup of the system, the characters of hydraulic and pneumatic, application and development trend. (知识点:液/气压传动与控制的基本工作原理,系统组成,液/气压传动的特点及应用和发展趋势) Emphasis: the basic operating principle and buildup of the system in hydraulic and pneumatic transmission. (重点:液/气压传动与控制的基本工作原理,系统组成) Difficulties: to grasp the two important characters that obtain fluid transmission. (难点:实现液压传动两个重要特征的理解) Homework: pp.349 Chapter 1, 1-1, 1-2, 1-3, and 1-4. Chapter 2 Fundamental Hydraulic Fluid Mechanics , 4 hours. (液压流 体力学基础, 4 学时) Knowledge points: hydrostatics, hydrodynamics, characteristics of fluid flow and pressure features of orifice and clearance in pipeline, hydraulic shock and cavitatio. (知识点:液体静力学、液体动力学、管道中液流的特性、孔口及缝隙的压力流量特性、液压冲击和气穴现象) Emphasis: to grasp material application of the fluid three equations and the pressure-flow rate features flowing through orifice and clearance. (重点:掌握流体动力学三大方程在液压传动中的具体应用,以及孔口及缝隙流的压力流量特性) Difficulties: to grasp the pressure-flow rate equation for orifice and clearance. (难点:对孔口及缝隙流的压力-流量特性方程的理解) 2.1 Performances of the Hydraulic Oil (液压油的性质) 8

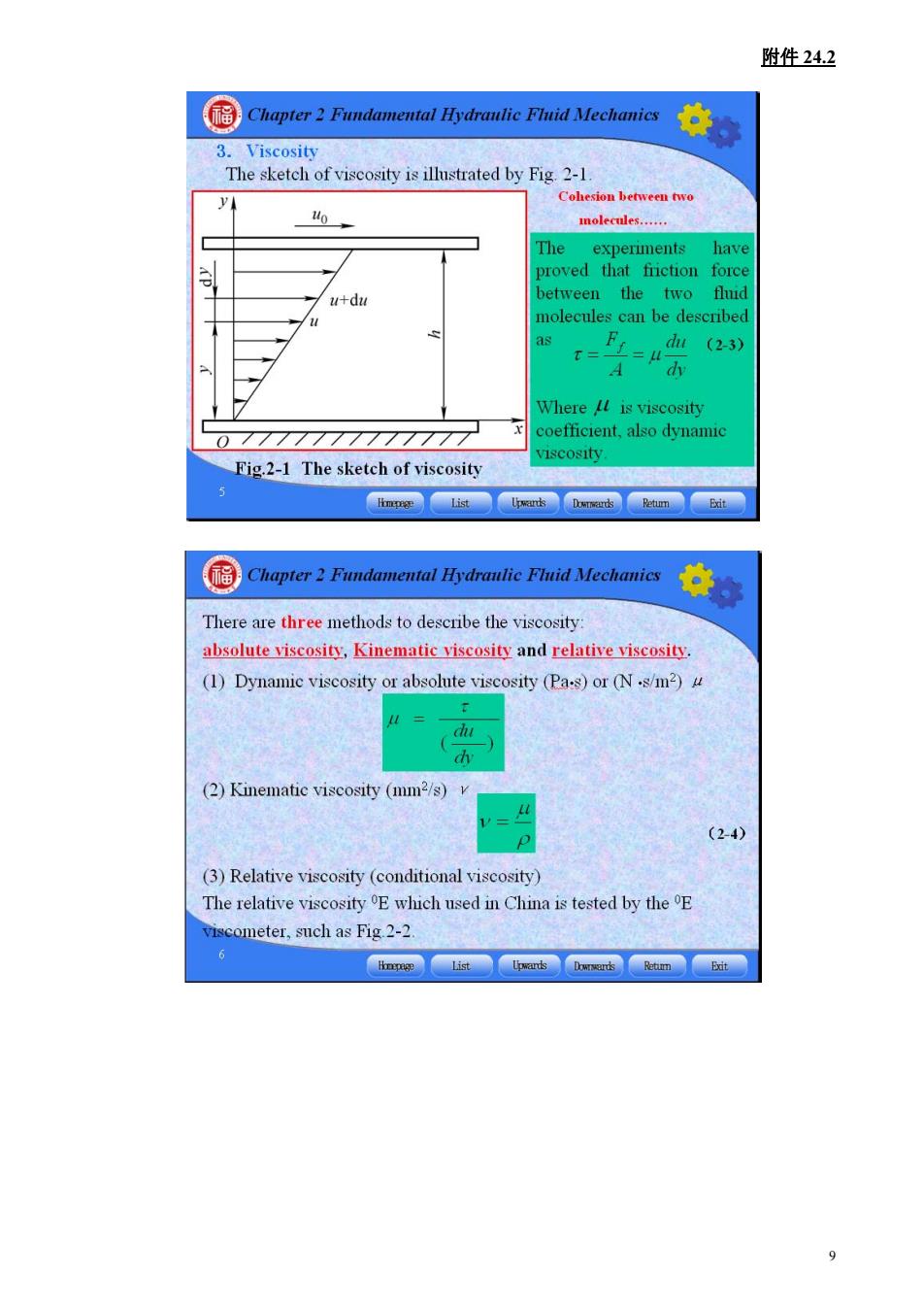

附件242 国Chopter2 damentl yrnie Fid e◆a 3 Viscosity The sketeh of viscosity is illustrated by Fig 2-1 Cohesion between two mnolecules. have u+du reen the twe fhud t= Where lt is viscosity coefficient,also dynamic Fig.2-1 The sketch of viscosity 国Chopter2 Fandamental历draieFid Mechanie年a There are three methods to describe the viscosity: absolute viscosity,Kinematic viscosity and relative viscosity. (1)Dynamie viscosity or absolute viscosity (Pa.s)or(Nm (2)Kinematic viscosity (mm2/s) =u (2-4) (3)Relative viscosity (conditional viscosity) The relative viscosity E which used in China is tested by the E iscometer,such as Fig.2-2. 9

附件 24.2 9

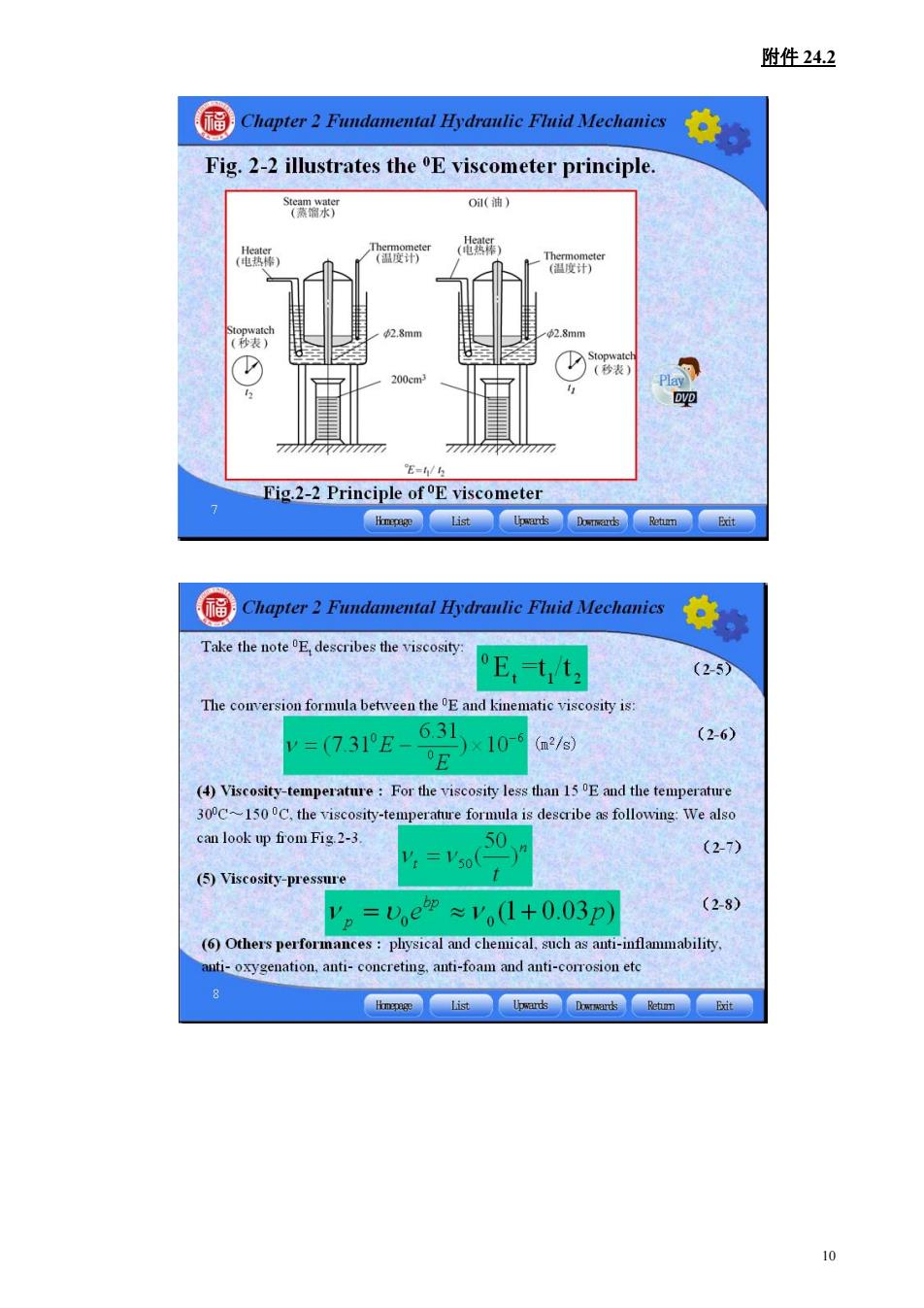

附件24.2 图capa2 Pndmontlyr Fid echnic。 Fig.2-2 illustrates the E viscometer principle. 《度 2.8mm E-/ Fig.2-2 Principle of E viscometer Take the noteE describes the viscosity E,=t t2 (2.5 on formula between theE and kinematic visco =(731°E 63 )×106a2/s) (2-6) (4Viscosity-temperature:For the viscosity less than 15E ad the temperature 3150C the viscosty-temperatre formula is desribeas following We also can look up from Fig2-3. (27) (5)Viscosity-pressure 。=v,ep≈y0+0.03p) (2-8) (6)Others performances:physical and chemucal.such as auti-inflammability. anti-oxygenation.anti-concreting,anti-foam and anti-corrosion etc 10

附件 24.2 10

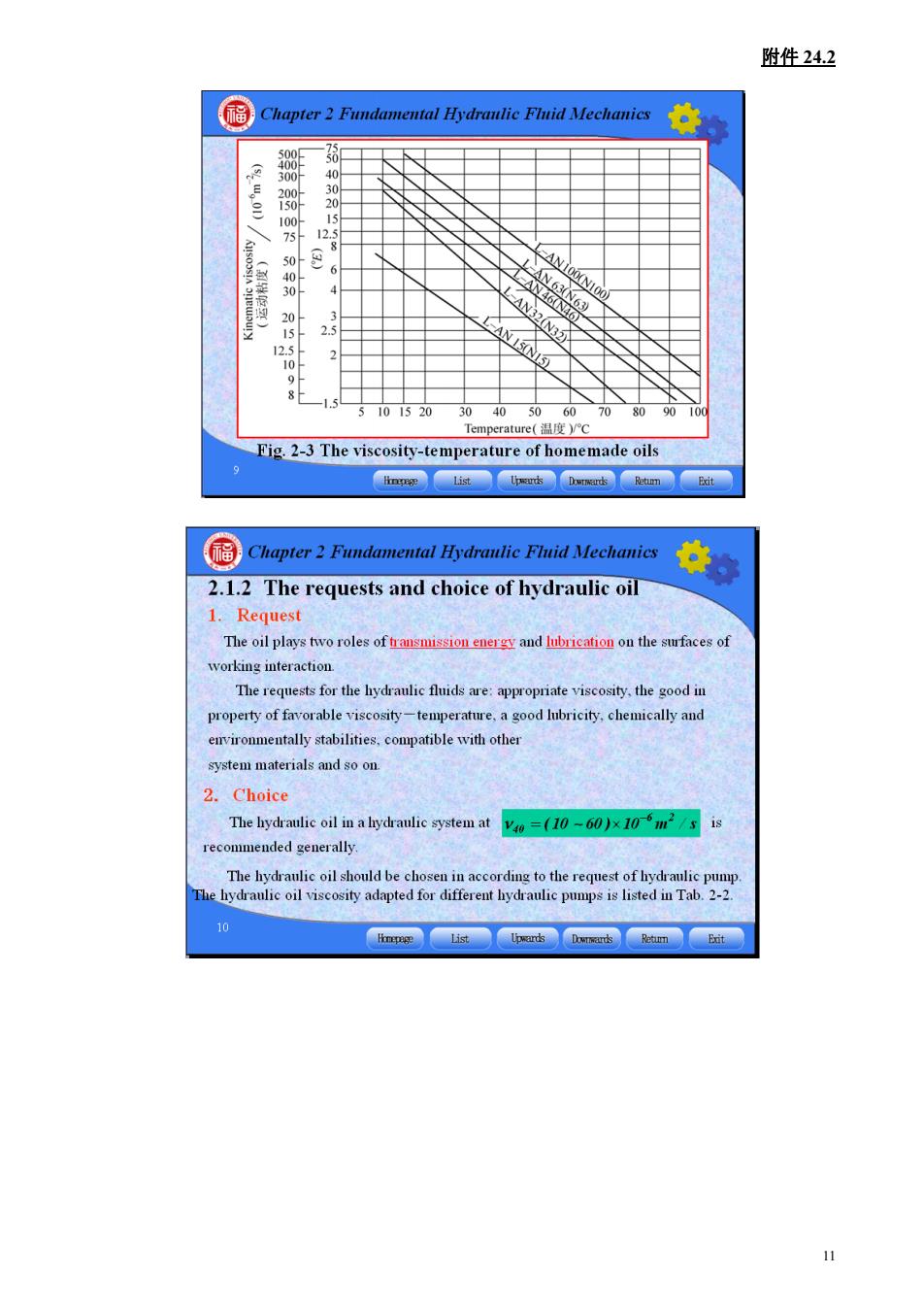

附件242 图Chapter2 Fndamental Hydranlic Fhnid Nechanies卷 () 101520304050 7080 0 Fig.2-3 The viscosity-temperature of homemade oils 2.1.2 The requests and choice of hydraulic oil 1.Request The oil plays two roles ofronand briction on the sfaces of working interaction The requests for the hydraulic fluids are:appropriate viscosity.the good i stabilities,compatibleith other system materials and so on 2.Choice The hydraulic oil in a hydraulic system atv0)x1m2s is generally. The hydraulic oil should be chosen in according to the request of hydraulic pump e hydraulic oil viscosity adapted for different hydraulic pumps is listed in Tab.2-

附件 24.2 11

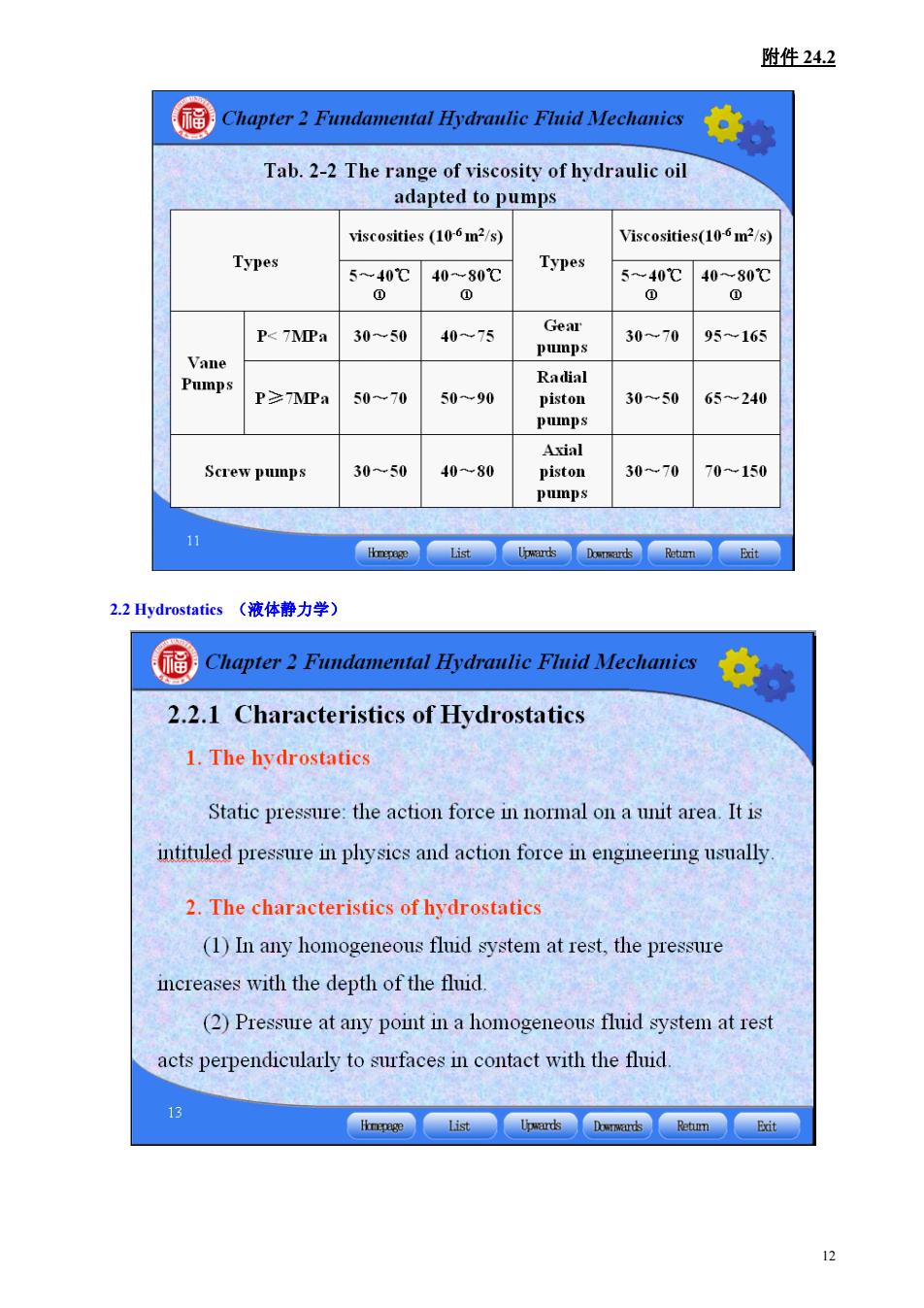

附件24.2 Tab.2-2 The range of viscosity of hydraulic oil adapted to pumps viscosities(106m2/s) Viscosities(106m2/s) Types 540℃ Types 40℃400 P<7MPa 30-50 40-75 Gear 30-7095-165 pumps Vane Radial P≥7P: 50-70 50-90 piston 30-50 65-240 pumps Axial Screw pumps 30-50 40-80 3070 70-150 List 2.2 Hydrostatics(液体静力学) Chapter2 Fundamental Hydraulic Fhuid Mechanics 2.2.1 Characteristics of Hydrostatics 1.The hydrostatics Static pressure:the action force in normal on a unit area.It is ntituled pressure in physics and action force in engineering usually 2.The characteristics of hydrostatics (1)In any homogeneous fluid system at rest,the pressure creases with the depth of the fluid. (2)Pressure at any point in a homogeneous fluid system at rest acts perpendicularly to surfaces in contact with the fluid. 12 Hmpee List Upeards Dorsvcards Retum Eit

附件 24.2 2.2 Hydrostatics (液体静力学) 12

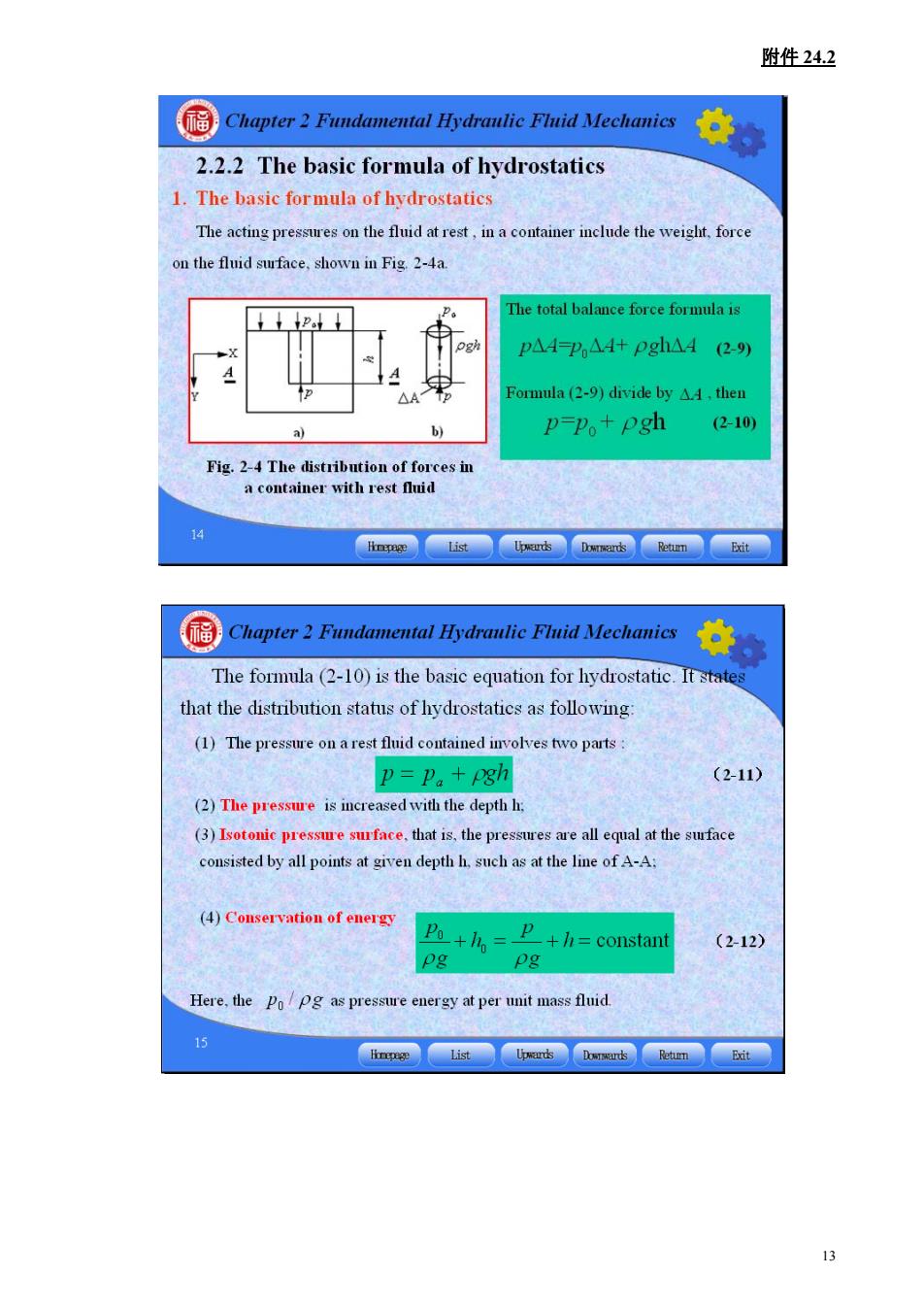

附件242 Chapter2 Fundamental Hydranlic Fluid Mechanics 2.2.2 The basic formula of hydrostatics 1.The basic formula of hydrostatics The acting pressures on the fluid at rest,in a container include the weight,force on the fluid surface,shown in Fig 2-4a The total balance force formula is pA4p,△d+Pgh△429 A mula (2-9)divide by then (2-10 a b p=P。+pgh Fig.2-4 The distribution of forces in a container with rest fluid 国Chapter2 Fundamental历dranlie Fid Mechanies年 The formula (2-10)is the basic equation for hydrostatic.It states that the distribution status of hydrostatics as following: (1)The pressure on a rest fluid coutained involves two parts: P=P。+8h (2-11) (2)The pressure with the depthh (3)Isotonic pressure surface,that is,the pressures are all equal at the surface consisted by all points at given depth h.such as at the line ofA (4)Conservation of energy +h=P+h=constant (2-12) pg Here.the Popg as pressure energy at per uit mass fluid

附件 24.2 13