附件24.1 《液压与气压传动》英汉双语教学大纲 (课程编号:00200397) 福州大学机械工程及自动化学院 陈淑梅 一、课程中英文名称 中文名称 液压与气压传动 英文名称 Hydraulic and Pneumatic Transmission 二、授课对象与学时 机械设计生制造及自动化、车辆工程 授课对 The vehicle engineering 总学时 50 其中实验(上机)学时 6 三、本课程与其他课程的联系 先修课程 机城炎基础课程,流体力学,高等数学,控制理论基础 The basic courses of enginery,fluid mechanics,mathematics and the control theory 无 后续课程 四、课程的敏学目的 The the comprehensive knowledge of hydraulic and pneumatic transmission in three aspects. (通过《液压与气动技术》课程的教学,使学生在三个方面获得知识): eentkhscootccopgacepk,caatespocaiaotcce (使学生掌握液压与气动的基猫知识,掌握各种液压元件的工作原理、特点、应用和选用方法) 2.Know well functions,buildup of hydraulic and pneumatic circuts and the application areas,know the achievements of advanced hydraulic and pneumatic technology used in the mechanical industries. (熟器各类液压基本回路的功能、组成和应用场合,了解国内外先进的液压技术和成果在机械设公 中的应用) 3.Students can beenhanced in the practice abilityby the experimenta operating by this course (通过液压传动实验课使学生增强其感性认识,并培养学生实际动手能力) Try to let students to acquire theory knowledge from three aspects cultivation mentioned above. (通过以上三个方面的培养,从而为学生从事液压与气动技术的设计和应用打下理论基础》 五、课程散学的主要内容 Chapter 1 Introduction to Hydraulic and Pneumati Transmission,2 hours.(液压与气压传动概论,2学时) Knowledge points:the basic operating principle.buildup of the system.the characters of hydraulic and pneumatic application and development trend. (知识点:液气压传动与控制的基本工作原理,系统组成,液/气压传动的特点及应用和发展趋势) Emphasis:the basic ystem in hydraulie and pneu

附件 24.1 1 《液压与气压传动》英汉双语教学大纲 (课程编号:00200397) 福州大学机械工程及自动化学院 陈淑梅 一、课程中英文名称 中文名称 液压与气压传动 英文名称 Hydraulic and Pneumatic Transmission 二、授课对象与学时 授课对象 机械设计制造及自动化、车辆工程 The students major in mechanical design, manufacture and automatization; and vehicle engineering 总学时 50 其中实验(上机)学时 6 三、本课程与其他课程的联系 先修课程 机械类基础课程,流体力学,高等数学,控制理论基础 The basic courses of enginery, fluid mechanics, mathematics and the control theory 后续课程 无 none 四、课程的教学目的 The students can acquire the comprehensive knowledge of hydraulic and pneumatic transmission in three aspects. (通过《液压与气动技术》课程的教学,使学生在三个方面获得知识): 1.To obtain the basic knowledge: the operation principle, characters, application and the method of choice for kinds of components of hydraulic and pneumatic transmission system. (使学生掌握液压与气动的基础知识,掌握各种液压元件的工作原理、特点、应用和选用方法) 2.Know well functions, buildup of hydraulic and pneumatic circuits and the application areas; know the achievements of advanced hydraulic and pneumatic technology used in the mechanical industries. (熟悉各类液压基本回路的功能、组成和应用场合,了解国内外先进的液压技术和成果在机械设备 中的应用) 3.Students can be enhanced in apperceiving and acquired the practice ability by the experimental operating by this course (通过液压传动实验课使学生增强其感性认识,并培养学生实际动手能力) Try to let students to acquire theory knowledge from three aspects cultivation mentioned above. (通过以上三个方面的培养,从而为学生从事液压与气动技术的设计和应用打下理论基础) 五、课程教学的主要内容 Chapter 1 Introduction to Hydraulic and Pneumatic Transmission , 2 hours.(液压与气压传动概论, 2 学时) Knowledge points: the basic operating principle, buildup of the system, the characters of hydraulic and pneumatic, application and development trend. (知识点:液/气压传动与控制的基本工作原理,系统组成,液/气压传动的特点及应用和发展趋势) Emphasis: the basic operating principle and buildup of the system in hydraulic and pneumatic

附件24.1 transmission (重点:液/气压传动与控制的基本工作原理,系统组成》 Difficulties.to grasp the two important ch ters that obtain fluid transmission (雄点:实现液压传动两个承要特征的理解) l.1 Study on Hydraulic and Pneumatic Transmission(液压与气压传动的研究内容) l.2 Operating Principles of Hydraulic Transmission(液压传动的工作原理) .13 Composition of Hydraulic Transmission System(液压传动系统的组成) .4 Features of Hydrauic and Pneumatic Transmission(液压与气压传动的特点 1.5 The Development History and Application of Hydraulic and Pneumatic Technology (液压与气压传动发展及应用概况) Homework:pp.349 Chapter 1,1-1,1-2,1-3,and 1-4. Chapter 2 Fundamental Hydraulic Fluid Mechanics,4 hours. (液压流体力学基础,4学时) Knowledge poin hydrostatics,.of fuid flow and pressure features fice and cle (知识点:液体静力学、液体动力学、管道中液流的特性、孔口及缝隙的压力流量特性、液压冲击剂 气穴现象) Emphasis:to grasp material application of the fluid threequations and the pressure-flow rate feature flowing through orifice and clearance (重点:掌据流体动力学三大方程在液压传动中的具体应用,以及孔口及缝隙流的压力流量特性)》 (难点:对孔口及缝隙流的压力一流量特性方程的理解) 2.Performances of the Hydraulic Oil(液压油的性质) 2.2 Hydrostatics(液体静力学) Homework:pp.349 Chapter 2.2-1.2-2.2-3.2-4 2.3 Hydrodynamics(液体动力学) 2.4 Characteristics of Fluid Flow in Pipeline(管道中液流的特性) 2.5 Flow Rate and Pressure Features of Orifice(孔口及缝隙的压力流量特性) 2.6 Hydraulic Shock and Cavitation(液压冲击和气穴现象) H0mew0rkpp.349 Chapter2,2-72-&2-9,2-10,2-1l,2-12 Answer to problems-1,2 hours.(习题讲解l,2学时) Lectures,questions and answers to the homework of chapters 1 and 2 for students in classroom.(Neglect) Chapter3 Hydraulic Pumps,4 hours.(液压泵,4学时) Knowledge points:the operating principle and types of hydraui pumps.the structure features of gear pumps,vane pumps and piston pumps and choose of pumps. (知识点:液压泵的工作原理和类型,各种柱塞系、叶片泵和齿轮桑的结构特点及工作原理,液压泵选 用 Emphasis:The and feature of variable pumps

附件 24.1 2 transmission. (重点:液/气压传动与控制的基本工作原理,系统组成) Difficulties: to grasp the two important characters that obtain fluid transmission. (难点:实现液压传动两个重要特征的理解) 1.1 Study on Hydraulic and Pneumatic Transmission (液压与气压传动的研究内容) 1.2 Operating Principles of Hydraulic Transmission (液压传动的工作原理) 1.3 Composition of Hydraulic Transmission System (液压传动系统的组成) 1.4 Features of Hydraulic and Pneumatic Transmission (液压与气压传动的特点) 1.5 The Development History and Application of Hydraulic and Pneumatic Technology (液压与气压传动发展及应用概况) Homework: pp.349 Chapter 1, 1-1, 1-2, 1-3, and 1-4. Chapter 2 Fundamental Hydraulic Fluid Mechanics , 4 hours. (液压流体力学基础, 4 学时) Knowledge points: hydrostatics, hydrodynamics, characteristics of fluid flow and pressure features of orifice and clearance in pipeline, hydraulic shock and cavitations. (知识点:液体静力学、液体动力学、管道中液流的特性、孔口及缝隙的压力流量特性、液压冲击和 气穴现象) Emphasis: to grasp material application of the fluid three equations and the pressure-flow rate features flowing through orifice and clearance. (重点:掌握流体动力学三大方程在液压传动中的具体应用,以及孔口及缝隙流的压力流量特性) Difficulties: to grasp the pressure-flow rate equation for orifice and clearance. (难点:对孔口及缝隙流的压力-流量特性方程的理解) 2.1 Performances of the Hydraulic Oil (液压油的性质) 2.2 Hydrostatics (液体静力学) Homework: pp.349 Chapter 2, 2-1, 2-2, 2-3, 2-4. 2.3 Hydrodynamics (液体动力学) 2.4 Characteristics of Fluid Flow in Pipeline (管道中液流的特性) 2.5 Flow Rate and Pressure Features of Orifice (孔口及缝隙的压力流量特性) 2.6 Hydraulic Shock and Cavitation (液压冲击和气穴现象) Homework: pp.349 Chapter 2, 2-7, 2-8, 2-9, 2-10, 2-11, 2-12. Answer to problems- 1 , 2 hours. (习题讲解-1,2 学时) Lectures, questions and answers to the homework of chapters 1 and 2 for students in classroom. (Neglect) Chapter 3 Hydraulic Pumps , 4 hours. (液压泵, 4 学时) Knowledge points: the operating principle and types of hydraulic pumps; the structure features of gear pumps, vane pumps and piston pumps and choose of pumps. (知识点:液压泵的工作原理和类型,各种柱塞泵、叶片泵和齿轮泵的结构特点及工作原理,液压泵选 用) Emphasis: The principle and feature of variable pumps

附件24.1 (重点:变量泉结构特点及工作原理。) :tograsp the features and variable method pump (难点:恒功案变量系的结构特点及变量原理) 3.I Introduction(概述) 3.2 Piston Pumps(柱塞泵) 3.3 Vane Pumps(叶片泵) 3.4 Gear Pumps(齿轮泵) Homework:pp.351 Chapter 3,3-1,3-2,3-3,3-4,3-5. Experiment1.Performance testing of hydraulic pumps,2 hours.(实验I、液压 泵性能试验,2学时) The main perfor oces for hydraulic pumps includes the rating e rcached the flow rate under the rating pre repulse,and ibration.Howeverh first three terms are important 液压泵的主要性能包括:能否达到额定压力、额定压力下的流量(额定流量),容积效常、压力脉动 (振摆)值、噪声、寿命、温升、振动等项,前三项是最重要的性能,泵的测试主要是检查这几项。 Equipment(主要仪器设各),OCS003(秦川QCS003型教学实验台) riment 2.The knocked-down experiment for hydraulic pump,2hours.( 2、秉的拆装试验,2半时) 1o grasp the structure res and ass emble steps of type of CB gear pump.type of YCY14-IB vane pumps and piston pumps.(了解CB型齿轮类油泵、YB型叶片油泵和YCYI4-IB型轴向柱塞泵的结构特点和 特配过程) Equipments:CB gear pump,.YCYI4-IBvane pumps an piston pumps.(若干套相关的液压条) Chapter4 ydraulic Actuators,4 hours.(液压热行元件,4 学时) Knowledge noints Grasp the structure features kinds of hydraulic motors and evlinders (知识点:液压执行元件的工作原理、特点和类型:各种液压马达、液压缸的结构特点和工作原理及设 计计算 Emphasis:to grasp the principle of power transmission for motors and hydraulic actuators. (重点:掌握和区别液压马达和液压缸实现能量转换的原理) Difficulties:the structure features of typical hydraulic motor and cylinder.and the design method. 难点:掌据典型的液压马达和被压缸的结均特点和结构设计 4.1 Hydraulic Mot (液压马达) 4.2 ydraulie Cylinders(液压缸) Homework:pp.351 Chapter 4,4-1,4-2,4-3,4-4,4-5,4-6. Chapter5 vdraulic Control Valves,6 hours.(液压控制 阀,6学时) Knowledge points:the basic operating principle,structure features and types of hydraulic valves.such as pressure valves flow valves and directional valves (知识点:各种方向液压阀:控制阀、压力控制阀、流量控制阀、插装阀、叠加倒和申液比例阀的结

附件 24.1 3 (重点:变量泵结构特点及工作原理。) Difficulties: to grasp the features and variable method of the constant power pumps. (难点:恒功率变量泵的结构特点及变量原理) 3.1 Introduction (概述) 3.2 Piston Pumps(柱塞泵) 3.3 Vane Pumps (叶片泵) 3.4 Gear Pumps (齿轮泵) Homework: pp.351 Chapter 3, 3-1, 3-2, 3-3, 3-4, 3-5. Experiment 1. Performance testing of hydraulic pumps, 2hours.(实验 1、液压 泵性能试验,2 学时) The main performances for hydraulic pumps includes the rating pressure reached, the flow rate under the rating pressure, volume efficiency, pressure pulse, notice, using life, temperature and vibration. However the first three terms are important. 液压泵的主要性能包括:能否达到额定压力、额定压力下的流量(额定流量),容积效率、压力脉动 (振摆)值、噪声、寿命、温升、振动等项,前三项是最重要的性能,泵的测试主要是检查这几项。 Equipment(主要仪器设备):QCS003(秦川 QCS003 型教学实验台) Experiment 2. The knocked-down experiment for hydraulic pump,2hours.(实验 2、泵的拆装试验,2 学时) To grasp the structure features and assemble steps of type of CB gear pump, type of YCY14-IB vane pumps and piston pumps.(了解 CB 型齿轮类油泵、YB 型叶片油泵和 YCY14-IB 型轴向柱塞泵的结构特点和 装配过程) Equipments: CB gear pump, YCY14-IB vane pumps and piston pumps. (若干套相关的液压泵) Chapter 4 Hydraulic Actuators, 4 hours.(液压执行元件,4 学时) Knowledge points: Grasp the structure features kinds of hydraulic motors and cylinders. (知识点:液压执行元件的工作原理、特点和类型;各种液压马达、液压缸的结构特点和工作原理及设 计计算) Emphasis: to grasp the principle of power transmission for motors and hydraulic actuators. (重点:掌握和区别液压马达和液压缸实现能量转换的原理) Difficulties: the structure features of typical hydraulic motor and cylinder, and the design method. (难点:掌握典型的液压马达和液压缸的结构特点和结构设计) 4.1 Hydraulic Motors (液压马达) 4.2 Hydraulic Cylinders (液压缸) Homework: pp.351 Chapter 4, 4-1, 4-2, 4-3, 4-4, 4-5, 4-6. Chapter 5 Hydraulic Control Valves,6 hours. (液压控制 阀 ,6 学时) Knowledge points: the basic operating principle, structure features and types of hydraulic valves,such as pressure valves, flow valves and directional valves. (知识点:各种方向液压阀:控制阀、压力控制阀、流量控制阀、插装阀、叠加阀和电液比例阀的结

附件24.1 构特点和工作原理) Emphasis disting ,manifold valves and cartridge valves,ydraul proportional valves,electro-hydraulic servo valves and electro-hydraulic digital valve (重点:区别一般开关式控制阀与插装阀、叠加阀和电液比例饲的结构和工作原理上的差别) Difficulties:differentiate and analysis the operating principle that realize the pressure,flow rate and directional control (难点:区别和分析实现压力、流量和方向控制的控制的工作原理) (液压阀概述)》 5.2 Directional Control Valves(方向控制阀) Homework:pp.352 Chapter 5.5-1.5-2.5-3.4-4. 5.3 Pressure Operated Valves(压力控制阀) Homework:pp.353 Chapter 5.5-5.5-6.5-7.4-8. 5.4 Flow Control Valves(流量控制阀) 5.5 Manifold Valves and Cartridge Valves(叠加阀和插装阀) 5.6 Electro-hydraulic Servo Valves(电液伺服阀) 57 e Valves(电液比例阀) 5.8 Electro-hydrauli Digital Valves(电液数字阀) Homework:pp.353 Chapter 5.5-10.5-11,5-12. Chapter 6 Auxiliary Components for Hydraulic Systems,3 hours.(液压辅件,3学时) Knowledge points:the types of auxiliary components for hydraulic systems ((知识点:液压辅助元件的类型,蓄能器、过滤器、油箱、管件、密封装置的基本结构、工作原理和 点) Emphasis:grasp the types and accumulators sealing devices (重点:掌鞋液压辅助元件的类型及工作原理。重点掌程典型的蓄能器、过滤器和密封装置的基本结 构、工作原理和特点) Difficulties:tvpical structure and application areas for accumulators.filters.reservoir.piping/tubing and connectors and seals and sealing device (难点:型的能器、过滤器、油箱、管仟、密封装置的基本结构、特点及应用场合】 6.1 Accumulators (蓄能器】 62 Filters(过波器) 6.3 Reservoir(油箱) 6.4 Piping/Tubing and Connectors(管件) 6.5 Seals and Sealing Devices (密封装置) Homework:pp.353 Chapter 6,6-1,6-2. Answer to problems-2,I hours. (习题讲解2,1学时) Chapter7 Basic Hydraulic Circuits.6 hours.(液压基本回

附件 24.1 4 构特点和工作原理) Emphasis: distinguish the difference in on-off valve, manifold valves and cartridge valves, electro-hydraulic proportional valves, electro-hydraulic servo valves and electro-hydraulic digital valves. (重点:区别一般开关式控制阀与插装阀、叠加阀和电液比例阀的结构和工作原理上的差别) Difficulties: differentiate and analysis the operating principle that realize the pressure, flow rate and directional control. (难点:区别和分析实现压力、流量和方向控制的控制的工作原理) 5.1 Introduction (液压阀概述) 5.2 Directional Control Valves (方向控制阀) Homework: pp.352 Chapter 5, 5-1, 5-2, 5-3, 4-4. 5.3 Pressure Operated Valves (压力控制阀) Homework: pp.353 Chapter 5, 5-5, 5-6, 5-7, 4-8. 5.4 Flow Control Valves (流量控制阀) 5.5 Manifold Valves and Cartridge Valves (叠加阀和插装阀) 5.6 Electro-hydraulic Servo Valves (电液伺服阀) 5.7 Electro-hydraulic Proportional Valves (电液比例阀) 5.8 Electro-hydraulic Digital Valves (电液数字阀) Homework: pp.353 Chapter 5, 5-10, 5-11, 5-12. Chapter 6 Auxiliary Components for Hydraulic Systems, 3 hours. (液压辅件,3 学时) Knowledge points: the types of auxiliary components for hydraulic systems. (知识点:液压辅助元件的类型,蓄能器、过滤器、油箱、管件、密封装置的基本结构、工作原理和 特点) Emphasis: grasp the types and operating principle of auxiliary components for hydraulic systems, such as accumulators, filters, seals and sealing devices. (重点:掌握液压辅助元件的类型及工作原理。重点掌握典型的蓄能器、过滤器和密封装置的基本结 构、工作原理和特点) Difficulties: typical structure and application areas for accumulators, filters, reservoir, piping/tubing and connectors and seals and sealing devices. (难点:典型的蓄能器、过滤器、油箱、管件、密封装置的基本结构、特点及应用场合) 6.1 Accumulators (蓄能器) 6.2 Filters(过滤器) 6.3 Reservoir(油箱) 6.4 Piping/Tubing and Connectors(管件) 6.5 Seals and Sealing Devices (密封装置) Homework: pp.353 Chapter 6, 6-1, 6-2. Answer to problems-2 , 1 hours. (习题讲解-2,1 学时) Chapter 7 Basic Hydraulic Circuits, 6 hours. (液压基本回

附件24.1 路,6学时) Knowedge basic for types,the operating priniple and feature for presseonorsspeed conotand directional onciruits. (知识点:被压本回路的基本性质、类型及特点,各类压力控制回路、速度控制、回路(一)调 速国路、速度控制回路(二)快速和速度换接回路、方向控制回路、多执行元件控制回路的工作原理 及特占) Emphasis control and directional control circuits (重点:掌界和理解实现各类典型的压力控制回路、速度控制回路、方向控制国路、多执行元件控制 回路的工作原理及特点) Difficulties:understand for typical operating principle and features for kinds of basic co (难点:各类奥型基本控制回路的实现及工作原理和特点:各元件在基木回路中的作用 7.1 Pressure Control Circuits(压力控制回路) 7.2 Speed Control Circuits(速度控制回路) 7.3 Directional Control Circuits(方向控制回路) 7.4Muti-actuator Control Circuits(多执行元件控制回路) Homework:pp.354 Chapter 7,7-4,7-5,7-6. Experiment 3.Circuits experimental of hydraulic basic circuits,2hours 压基本回路试验,2学时) The design and build uptwo kinds:diferent area circuit and realizing for different speed change (差动同路和速度换接回路的实现) Equipment:CSO140CS014.(型装配式液压回路实验台QCSO140CS014 Chapter8 Examples of Hydraulic Systems.2 hours.(典型液 压系统,2学时) Knowledge points introduction of 4 kinds of typical hydraulic system that are used in industry power-slipway for combined machine tools,YA32-200 type four column universal press machine,hydrauli system for plastic inctnmodn machine and hydraulc system of manipulator. (知识点:介绍外圆磨床液压系统、压力机液压系统、塑料注射成型机液压系统、和机械手液压系统 的特点及工作原理) Emp such as power-slipway fo inctinmouldin machine and hydraulisystem of manipulator. (重点:掌捏典型工业中应用的液压系统:压力机液压系统、塑料注射成型机液压系统和机械手液压 系统的特点及工作原理) The applica of com (难点:各类奥型液压系统的组成、特点和动作原理:系统中各元件的作用) 8.1 Hydraulic System of Power-slipway for Combined Machine Tools(组合机床动力滑台 液压系统) 82 Hydraulic System for Plastic Injection Moulding Machines(塑料注射成型机液压系 统)

附件 24.1 5 路, 6 学时)) Knowledge points: the basic characters for hydraulic circuits and types; the operating principle and features for pressure control circuits, speed control circuits and directional control circuits. (知识点:液压基本回路的基本性质、类型及特点,各类压力控制回路、速度控制 、回路(一)调 速回路、速度控制回路(二)快速和速度换接回路、方向控制回路、多执行元件控制回路的工作原理 及特点) Emphasis: comprehend the operating principle for three hydraulic circuits: pressure control, flow rate control and directional control circuits. (重点:掌握和理解实现各类典型的压力控制回路、速度控制回路、方向控制回路、多执行元件控制 回路的工作原理及特点) Difficulties: understand for typical operating principle and features for kinds of basic control circuits realizing. (难点:各类典型基本控制回路的实现及工作原理和特点;各元件在基本回路中的作用) 7.1 Pressure Control Circuits (压力控制回路) 7.2 Speed Control Circuits (速度控制回路) 7.3 Directional Control Circuits (方向控制回路) 7.4 Muti-actuator Control Circuits (多执行元件控制回路) Homework: pp.354 Chapter 7, 7-4, 7-5, 7-6. Experiment 3. Circuits experimental of hydraulic basic circuits, 2hours (液 压基本回路试验, 2 学时) The design and build up two kinds of hydraulic circuits: different area circuit and realizing for different speed change(差动回路和速度换接回路的实现) Equipment: QCSO14QCSO14. (型装配式液压回路实验台 QCSO14QCSO14) Chapter 8 Examples of Hydraulic Systems, 2 hours.(典型液 压系统,2 学时) Knowledge points: introduction of 4 kinds of typical hydraulic system that are used in industry, power-slipway for combined machine tools, YA32-200 type four column universal press machine, hydraulic system for plastic injection molding machine and hydraulic system of manipulator. (知识点:介绍外圆磨床液压系统、压力机液压系统、塑料注射成型机液压系统、和机械手液压系统 的特点及工作原理) Emphasis: to grasp the operating principle of typical hydraulic system in industry, such as power-slipway for combined machine tools, YA32-200 type four column universal press machine, hydraulic system for plastic injection moulding machine and hydraulic system of manipulator. (重点:掌握典型工业中应用的液压系统:压力机液压系统、塑料注射成型机液压系统和机械手液压 系统的特点及工作原理) Difficulties: understand for the composing, principle and features kinds of typical control circuits realizing. The application of components in the system. (难点:各类典型液压系统的组成、特点和动作原理;系统中各元件的作用) 8.1 Hydraulic System of Power-slipway for Combined Machine Tools (组合机床动力滑台 液压系统) 8.2 Hydraulic System for Plastic Injection Moulding Machines (塑料注射成型机液压系 统)

附件24.1 8.3 Hydraulic System of YA32-200 Type Four Column Universal Press Machine(YA32-200 型四柱万能液压机液压系统) 8.4 Hydraulic System of Manipulator(机械手液压系统) Homework:pp.358 Chapter 8,8-1. Chapter 9 Design of Hydraulic Transmission System,4 hours.(液压系统的设计计算,4学时) Knowedge points:the approach for hydrostatic circuits design,a design example of hydraulic system. (知识点:液压系统的设计步骤、液压系统的设计计算举例) Emphasis. appr stepsofhydiaulic bya lecture e (重点:通过具体的液压系统设计计算实例掌挥液压系统的设计步骤和方法) Difficulties:the design and checking computations. (难点,液压系统的设计与验算) 9.1 The Approach for Design of Hydraulie System(液压系统的设计步骤) 92 A Design Example of Hydrauli System(液压系统的设计计算实例) Homework:pp.360 Chapter 9,9-1. Chapter 10 Air Supply Devices and Pneumatic Components 4 hours.(气源装置与启动元件,4学时) Knowledge points:introduction the structure feature and operating principle for air supply devices regulating valves,actuators,and pneumatic attachments. (知识点:介绍气源装置、气动元件、气动执行元件、气动控制阀、气动辅件的结构特点及工作原理) Emphasis:the structure feature and operating principle ofir supply devices.regulating valves. (重点:掌握气源装置、气动执行元件、气动控制阀和气动辅件的结构特点及工作原理〉 Difficutie:the design and feature of kinds of the pneumatic elm (难点:各类气动元件的结构特点及设计) 10.1 Air supply Devices(气题装置) 10.2 Pneum tic Attachments(气动辅件) 0.3 Pneumatic Actuators(气动执行元件) I0.4 Pneumatic Regulating Valves(气动控制阀) Homework:pp.360 Chapter 10,10-1,10-2,10-3. Answer to problems-3 and Final reviews,2 hours.(习题进邂 3和总复习,2学时) 实每实 序号 实验名称 内容提要或要求 验组验 主要仪器没备 (Names) 学人类

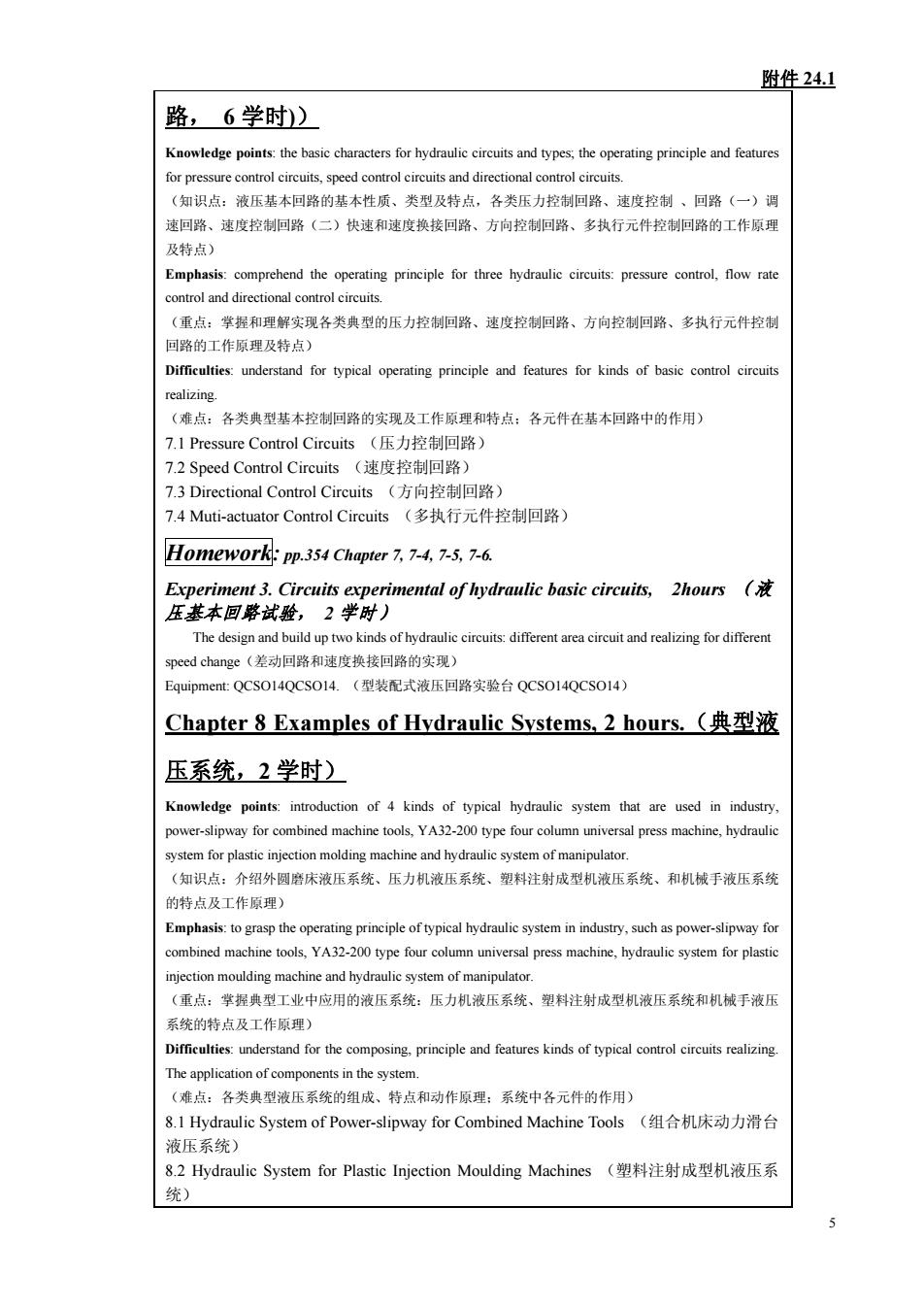

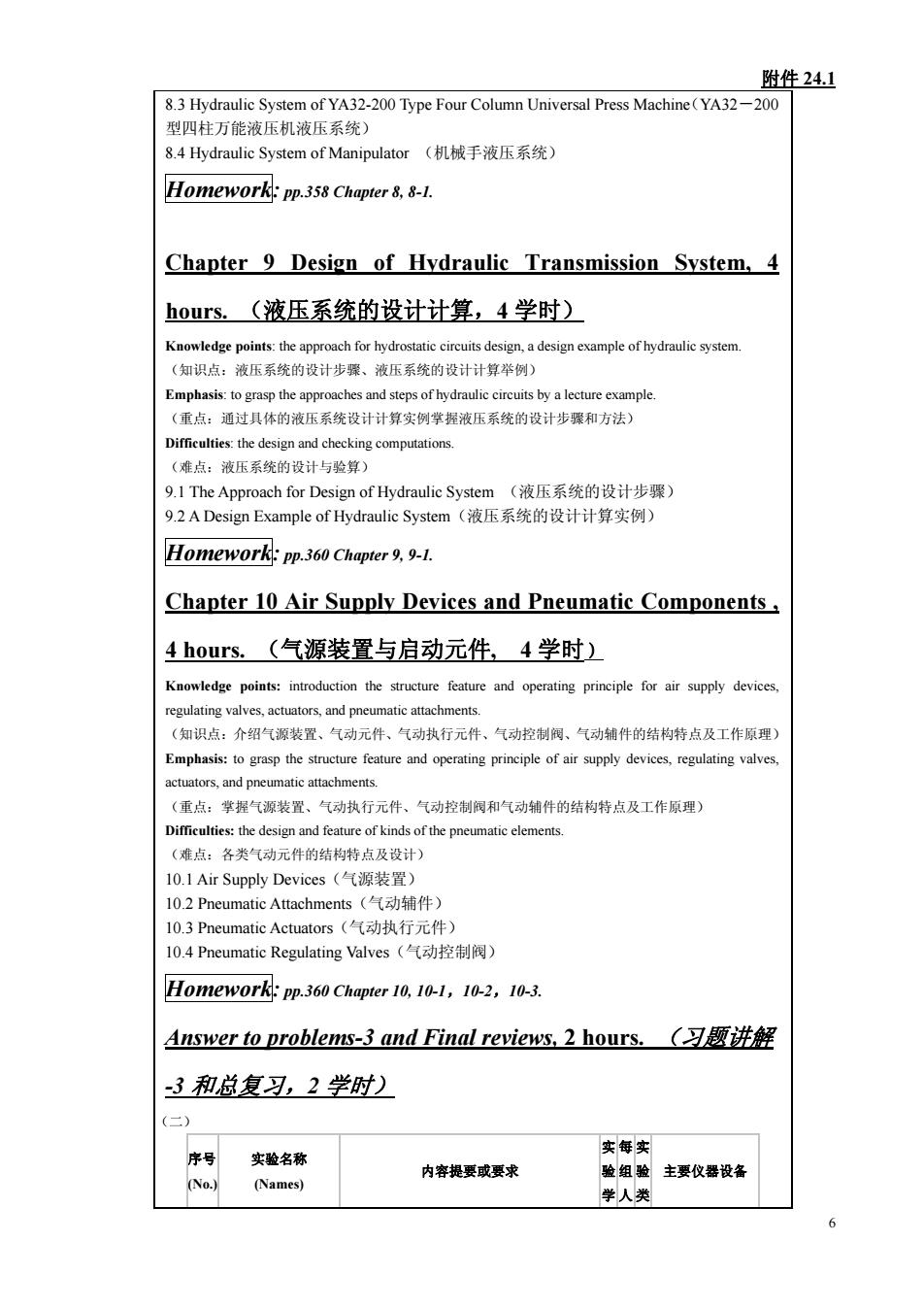

附件 24.1 6 8.3 Hydraulic System of YA32-200 Type Four Column Universal Press Machine(YA32-200 型四柱万能液压机液压系统) 8.4 Hydraulic System of Manipulator (机械手液压系统) Homework: pp.358 Chapter 8, 8-1. Chapter 9 Design of Hydraulic Transmission System, 4 hours. (液压系统的设计计算,4 学时) Knowledge points: the approach for hydrostatic circuits design, a design example of hydraulic system. (知识点:液压系统的设计步骤、液压系统的设计计算举例) Emphasis: to grasp the approaches and steps of hydraulic circuits by a lecture example. (重点:通过具体的液压系统设计计算实例掌握液压系统的设计步骤和方法) Difficulties: the design and checking computations. (难点:液压系统的设计与验算) 9.1 The Approach for Design of Hydraulic System (液压系统的设计步骤) 9.2 A Design Example of Hydraulic System(液压系统的设计计算实例) Homework: pp.360 Chapter 9, 9-1. Chapter 10 Air Supply Devices and Pneumatic Components , 4 hours. (气源装置与启动元件, 4 学时) Knowledge points: introduction the structure feature and operating principle for air supply devices, regulating valves, actuators, and pneumatic attachments. (知识点:介绍气源装置、气动元件、气动执行元件、气动控制阀、气动辅件的结构特点及工作原理) Emphasis: to grasp the structure feature and operating principle of air supply devices, regulating valves, actuators, and pneumatic attachments. (重点:掌握气源装置、气动执行元件、气动控制阀和气动辅件的结构特点及工作原理) Difficulties: the design and feature of kinds of the pneumatic elements. (难点:各类气动元件的结构特点及设计) 10.1 Air Supply Devices(气源装置) 10.2 Pneumatic Attachments(气动辅件) 10.3 Pneumatic Actuators(气动执行元件) 10.4 Pneumatic Regulating Valves(气动控制阀) Homework: pp.360 Chapter 10, 10-1,10-2,10-3. Answer to problems-3 and Final reviews, 2 hours. (习题讲解 -3 和总复习,2 学时) (二) 序号 (No.) 实验名称 (Names) 内容提要或要求 实 验 学 每 组 人 实 验 类 主要仪器设备

附件24.1 时粉烈 The main performances for hydraulic pumps ncludes the rating pressure reached,the flov ate under the rating pressure.volume Performance testing ssure pule notice,using life Tester:OCS003 of hydraulic pumps ms are importan 秦川QCS003型 (液压泉性能试验 教学实验台 (液压泵的主要性能包括:能否达到额定日 力、额定压力下的流量(额定流量),容积 效率、压力脉动(指摆)值、碳声、寿命 温升、振动等项,前三项是最重委的性能 泵的测试主要是检查这几项。) To grasp the structure features and assemble 若干套相关的液 teps of type of CB gear pump,type of 压须 The knocked-dowr YCY14-IB vane pumps and piston pumns experiment for (了解CB型齿轮类油泵 YB型叶片油 hydraulic pum 泵的拆装试验) 和YCY14B型轴向柱塞泵的结构特点和 vane pumps and 装配过程) piston pumps) Circuits Design and build up two kinds of hydraulic Tester OCS014 draulic basic 差动回路和速度换接回路的实现) 液压基本可路试验 六、教材和主要参考资 教材 陈淑梅编著。《液压与气压传动》英汉双语普通高等教育 (text book) 一五”规划教材.ISBN978-7-111-22449-5.机械工业出 版社.2007,10. 1]Frank M.White.Fluid Mechanics(Fourth Edition)[M).Printer:Vor Hoffmann Press,Inc.1999. Merle C.Potter.David C.Wiggert.Mechanics of fluids [M].Beijing China machine press,2003 3JAntony Barber,Pneumatic Handbook.7 Edition [M].The Trade Technical Press Limited.1989. 41 Ronald E Glenn.James E Blinn.Mobile Hydraulic TestinglMI 1970 5]D.Mecloy,H.R.Martin,The control of fluid power [M].Lower Brydone(Printers)Ltd Thetford,Norfolk,1973. 6]Raymond PLambeck.Hydraulic Pumps and Motors:Selection an Application for Hydraulic Power Control Systems [M].Markce Dekker.INC.1983. 7]Hehn Anton H.Fluid Power Troubleshooting [M].Marcel Dekker

附件 24.1 7 时 数 型 01 Performance testing of hydraulic pumps (液压泵性能试验) The main performances for hydraulic pumps includes the rating pressure reached, the flow rate under the rating pressure, volume efficiency, pressure pulse, notice, using life, temperature and vibration. However the first three terms are important. (液压泵的主要性能包括:能否达到额定压 力、额定压力下的流量(额定流量),容积 效率、压力脉动(振摆)值、噪声、寿命、 温升、振动等项,前三项是最重要的性能, 泵的测试主要是检查这几项。) 2 10 设 计 Tester: QCS003 秦川 QCS003 型 教学实验台 02 The knocked-down experiment for hydraulic pump. (泵的拆装试验) To grasp the structure features and assemble steps of type of CB gear pump, type of YCY14-IB vane pumps and piston pumps. (了解 CB 型齿轮类油泵、YB 型叶片油泵 和 YCY14-IB 型轴向柱塞泵的结构特点和 装配过程) 2 10 认 识 若干套相关的液 压泵 (Tester: CB gear pump, YCY14-IB vane pumps and piston pumps) 03 Circuits experimental of hydraulic basic circuits. 液压基本回路试验 Design and build up two kinds of hydraulic circuits: different area circuit and realizing for different speed change. (差动回路和速度换接回路的实现) 2 10 设 计 Tester: QCSO14 (QCSO14 型装配 式液压回路实验 台) 六、教材和主要参考资料 教材 (text book) 陈淑梅编著.《液压与气压传动》英汉双语.普通高等教育 “十一五”规划教材. ISBN 978-7-111-22449-5. 机械工业出 版社. 2007,10. References 参考资料 [1] Frank M. White. Fluid Mechanics (Fourth Edition) [M]. Printer: Von Hoffmann Press,Inc. 1999. [2] Merle C. Potter, David C. Wiggert. Mechanics of fluids [M]. Beijing, China machine press, 2003. [3]Antony Barber, Pneumatic Handbook, 7th Edition [M]. The Trade & Technical Press Limited. 1989. [4] Ronald E Glenn, James E Blinn, Mobile Hydraulic Testing[M]. 1970. [5] D. Mccloy, H.R. Martin, The control of fluid power [M]. Lower & Brydone (Printers) Ltd., Thetford, Norfolk, 1973. [6] Raymond P Lambeck. Hydraulic Pumps and Motors: Selection and Application for Hydraulic Power Control Systems [M]. Markcel Dekker, INC, 1983. [7] Hehn Anton H. Fluid Power Troubleshooting [M]. Marcel Dekker

附件24.1 NC.1984. ]George R Keller.Hydraulic System Analysis.1970. 9JLansky,Lawrence F Schrader Jr.Industrial Pneumatic Contro Marcel Dekker,INC,1986. 10]JKom.Hydraulicstaic Transmission System.Interational Texboo Company Ltd 158,Buckingham Palace Road London SW1.1969. 1]陈淑梅.液压传动.多媒体教学自学软件M.北京:机械工业出 版社,2001. 2】雷天觉。新编液压工程手册.上、下册M.北京:北京理工大号 出版社,1998. 13】许福玲,陈尧明.液压与气压传动.2版M.北京:机械工业出 版社,2004. 14左健民.液压与气压传动.3版M北京:机械工业出版社 2006. 15)]章宏甲.液压与气压传动M北京:机械工程出版社,20O5 16)]袁承训.液压与气压传动.2版M.北京:机械工业出版社 2000. 17刀何存兴,张铁华.液压与气压传动.2版M.武汉:华中科技大 学出版社,2000

附件 24.1 8 INC. 1984. [8] George R Keller. Hydraulic System Analysis. 1970. [9]Z J Lansky, Lawrence F Schrader Jr. Industrial Pneumatic Control. Marcel Dekker, INC, 1986. [10] J Korn. Hydraulicstaic Transmission System. International Texbook Company Ltd 158, Buckingham Palace Road London SW1. 1969. [11] 陈淑梅. 液压传动.多媒体教学/自学软件[M]. 北京:机械工业出 版社,2001. [12] 雷天觉。新编液压工程手册.上、下册 [M]. 北京:北京理工大学 出版社,1998. [13] 许福玲,陈尧明. 液压与气压传动.2 版 [M]. 北京:机械工业出 版社,2004. [14] 左健民. 液压与气压传动. 3 版 [M]. 北京:机械工业出版社, 2006. [15] 章宏甲. 液压与气压传动 [M]. 北京:机械工程出版社, 2005. [16] 袁承训. 液压与气压传动. 2 版 [M]. 北京:机械工业出版社, 2000. [17] 何存兴,张铁华. 液压与气压传动. 2 版 [M]. 武汉:华中科技大 学出版社, 2000