产品计算分批法 1分批法的含义及应用范围 2分批法的特点 3分批法的计算程序及会计核算 4 分批法举例一一间接费用当月分配法 5分批法举例一一间接费用累计分配法

产品计算分批法 1 分批法的含义及应用范围 2 分批法的特点 3 分批法的计算程序及会计核算 4 分批法举例——间接费用当月分配法 5 分批法举例——间接费用累计分配法

分批法的含义及应用范围 Job order costing >分批法亦称订单法,它是以产 品的批别或订单为计算对象, 设置明细帐,归集费用,计算 产品成本的一种方法 >分批法的适用范围 口单件小批生产类型的企业, 比如:船舶、重型机械以 及精密仪器、专用设备的 生产企业 兼p故ess costing兼女 口新产品的试制、工业性修 理作业和辅助生产的工具 模具制造

分批法的含义及应用范围 ➢ 分批法亦称订单法,它是以产 品的批别或订单为计算对象, 设置明细帐,归集费用,计算 产品成本的一种方法 ➢ 分批法的适用范围 单件小批生产类型的企业, 比如:船舶、重型机械以 及精密仪器、专用设备的 生产企业 新产品的试制、工业性修 理作业和辅助生产的工具 模具制造 COLA Job order costing Process costing

Which Costing System? Tax Return

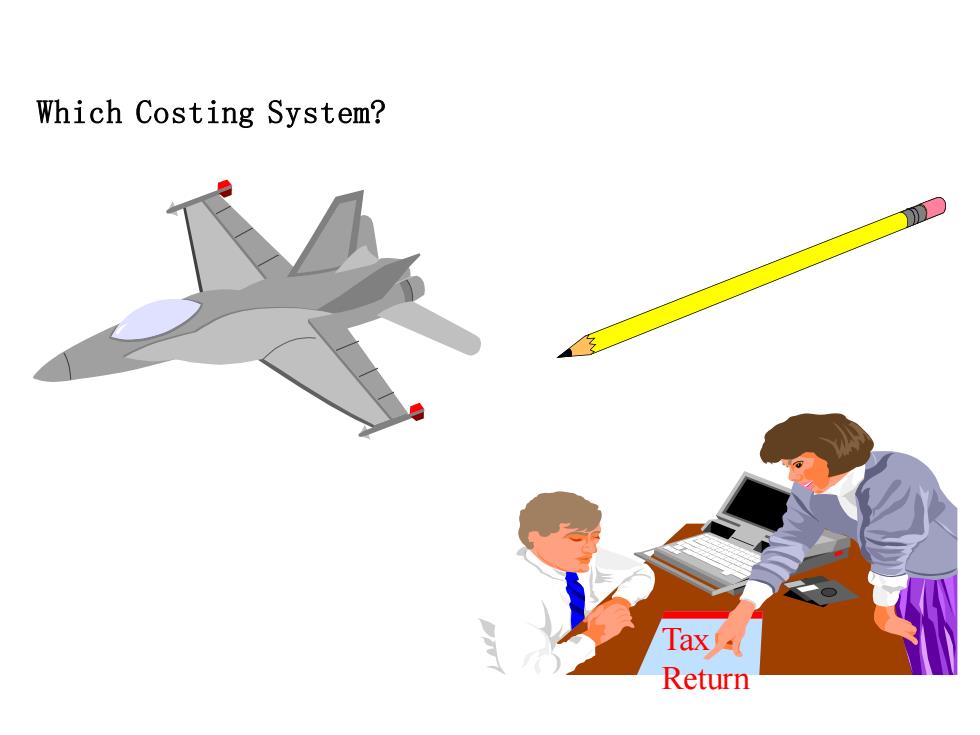

Which Costing System? Tax Return

Job Order Costing System >Each job is a cost object以产品的批别或订单作为成本计算对象:批 别定单别,划分批别需考虑①一批分几单,几单组成一批②实际需要, 最佳批量,能力,交货日期要求 >Accumulate costs for each job Use subsidiary ledger WIP Subsidiary Ledger Job 1 Job 2 Job 3 WIP Control 100 200 500 Job 1 100 Job 2 200 Job 3 500 Total 800 Job 1 Job 2+Job 3 WIP Control

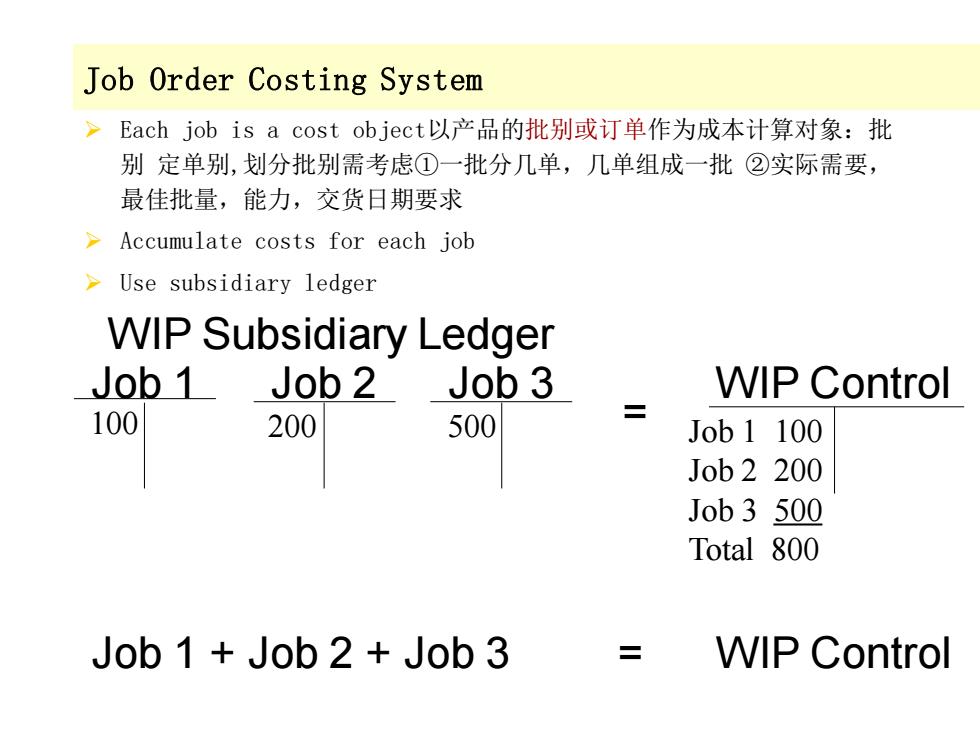

Job Order Costing System ➢ Each job is a cost object以产品的批别或订单作为成本计算对象:批 别 定单别,划分批别需考虑①一批分几单,几单组成一批 ②实际需要, 最佳批量,能力,交货日期要求 ➢ Accumulate costs for each job ➢ Use subsidiary ledger Job 1 Job 2 Job 3 WIP Control Job 1 + Job 2 + Job 3 = WIP Control WIP Subsidiary Ledger = Job 1 100 Job 2 200 Job 3 500 Total 800 100 200 500

分批法的计算程序及会计核算 1.根据“生产任务通知单”设置各批次或订单的产品成本计算单 2.归集和分配各种要素费用 3.归集并分配各辅助生产车间发生的费用 4.采用“当月分配法”或“累计分配法”分配基本生产车间的制造 费用 5.在某批产品批量较大,而且跨越生产或分次交货时,计算并分配 完工产品成本和月末在产品成本 6.结转完工入库产品的成本

分批法的计算程序及会计核算 1. 根据“生产任务通知单”设置各批次或订单的产品成本计算单 2. 归集和分配各种要素费用 3. 归集并分配各辅助生产车间发生的费用 4. 采用“当月分配法”或“累计分配法”分配基本生产车间的制造 费用 5. 在某批产品批量较大,而且跨越生产或分次交货时,计算并分配 完工产品成本和月末在产品成本 6. 结转完工入库产品的成本

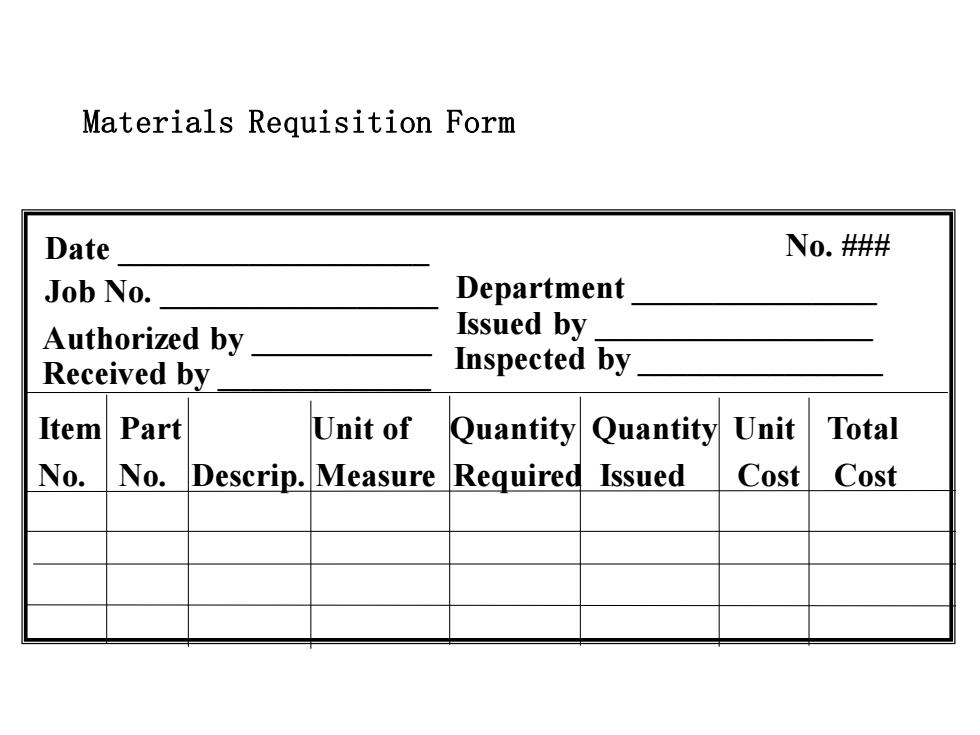

Material Requisition Form >Tracks who is responsible for materials >Verifies flow of materials from warehouse to department to job >Journal entry Work in Process Inventory (direct material) Manufacturing Overhead (indirect material) Raw Material Inventory

Material Requisition Form ➢ Tracks who is responsible for materials ➢ Verifies flow of materials from warehouse to department to job ➢ Journal entry Work in Process Inventory (direct material) Manufacturing Overhead (indirect material) Raw Material Inventory

Materials Requisition Form Date N0.## Job No. Department Authorized by Issued by Received by Inspected by Item Part Unit of Quantity Quantity Unit Total No. No.Descrip.Measure Required Issued Cost Cost

Materials Requisition Form Date _ No. ### Job No. _ Authorized by _ Department _ Issued by _ Inspected by _ Item Part Unit of Quantity Quantity Unit Total No. No. Descrip. Measure Required Issued Cost Cost Received by _

Job Order Cost Sheet >All financial information about a job direct material (from material requisition) direct labor (from time sheets or labor tickets) ▣applied overhead budgeted cost information >When job is complete,use job order cost sheet to analyze actual costs to budgeted costs

Job Order Cost Sheet ➢ All financial information about a job direct material (from material requisition) direct labor (from time sheets or labor tickets) applied overhead budgeted cost information ➢ When job is complete, use job order cost sheet to analyze actual costs to budgeted costs

Job Order Cost Sheet Customer Job No.### Starting Date_ Job Description_ Completion Date Contract Price Materials Direct Labor Overhead Applied Date Ref#Amount Date Ref#Amount Date Ref#Amount Total Materials Total Labor Total Cost of Job Total OH Applied

Job Order Cost Sheet Customer _ Job No. ### Starting Date _ Job Description _ Completion Date _ Contract Price _ Materials Date Ref# Amount Direct Labor Date Ref # Amount Overhead Applied Date Ref# Amount Total Materials _ Total Labor _ Total Cost of Job Total OH Applied _ ========

Employee Time Sheet >Time worked on each job >Journal entry Work in Process Inventory (direct labor) Overhead (indirect labor) Salaries and Wages Payable

Employee Time Sheet ➢ Time worked on each job ➢ Journal entry Work in Process Inventory (direct labor) Overhead (indirect labor) Salaries and Wages Payable