management ninth edition STEPHEN P.ROBBINS MARY COULTER 斯蒂芬p罗宾斯 玛丽库尔特 Chapter 19 Operations and Value 第十九章 Chain Management 运营及价值链管理 PEARSON 2007 Prentice Hall,Inc. PowerPoint Presentation by Charlie Cook All rights reserved. The University of WestAlabama

ninth edition STEPHEN P. ROBBINS PowerPoint Presentation by Charlie Cook The University of West Alabama MARY COULTER © 2007 Prentice Hall, Inc. All rights reserved. Operations and Value Chain Management 运营及价值链管理 斯蒂芬·p·罗宾斯 玛丽·库尔特 Chapter 19 第十九章

LEARNING OUTLINE要点概览 Follow this Learning Outline as you read and study this chapter. 根据以下要点概览阅读和学习本章 What Is Operations Management and Why Is It Important? 什么是运营管理,他为什么重要? Explain what operations management is. ·解释什么是运营管理 Contrast manufacturing and services organizations. ·比较制造业和服务业 Describe managers'role in improving productivity. ·描述管理者在提高生产率过程中的作用 Discuss the strategic role of operations management. ·详述运营管理的战略作用 Value Chain Management价值链管理 Define value chain and value chain management. ·定义价值和价值链管理 Describe the goal of value chain management. ·描述价值链管理的目标 Discuss the requirements for successful value chain management. ·详述成功的价值链管理的要求 2007 Prentice Hall,Inc.All rights reserved. 19-2

© 2007 Prentice Hall, Inc. All rights reserved. 19–2 L E A R N I N G O U T L I N E 要点概览 Follow this Learning Outline as you read and study this chapter. 根据以下要点概览阅读和学习本章 What Is Operations Management and Why Is It Important? 什么是运营管理,他为什么重要? • Explain what operations management is. • 解释什么是运营管理 • Contrast manufacturing and services organizations. • 比较制造业和服务业 • Describe managers’ role in improving productivity. • 描述管理者在提高生产率过程中的作用 • Discuss the strategic role of operations management. • 详述运营管理的战略作用 Value Chain Management 价值链管理 • Define value chain and value chain management. • 定义价值和价值链管理 • Describe the goal of value chain management. • 描述价值链管理的目标 • Discuss the requirements for successful value chain management. • 详述成功的价值链管理的要求

LEARNING OUTLINE (cont'd) 要点概览(续) Follow this Learning Outline as you read and study this chapter. 据以下要点概览阅读和学习本章 Value Chain Management(cont'd) 价值链管理(续) Describe the benefits that result from value chain management. ·描述进行价值链管理的优点 Explain the obstaclesto value chain management. ·解释进行价值链管理的障碍 Current Issues in Operations Management 当前运营管理的问题 Discusstechnology's role in manufacturing. ·详述技术在生产过程中的作用 Tellsome of the various quality dimensions. ·列举一些不同的质量维度 Explain ISO 9000 and Six Sigma. ·解释S09000和六西格玛 Describe mass customization and how operations management contributes to it. ·描述批量定制以及运营管理如何对其起作用 2007 Prentice Hall,Inc.All rights reserved 19-3

© 2007 Prentice Hall, Inc. All rights reserved. 19–3 L E A R N I N G O U T L I N E (cont’d) 要点概览(续) Follow this Learning Outline as you read and study this chapter.根 据以下要点概览阅读和学习本章 Value Chain Management (cont’d) 价值链管理(续) • Describe the benefits that result from value chain management. • 描述进行价值链管理的优点 • Explain the obstacles to value chain management. • 解释进行价值链管理的障碍 Current Issues in Operations Management 当前运营管理的问题 • Discuss technology’s role in manufacturing. • 详述技术在生产过程中的作用 • Tell some of the various quality dimensions. • 列举一些不同的质量维度 • Explain ISO 9000 and Six Sigma. • 解释ISO9000和六西格玛 • Describe mass customization and how operations management contributes to it. • 描述批量定制以及运营管理如何对其起作用

What Is Operations Management? 什么是运营管理 ·Operations Management运营管理 The design,operation,and control of the transformation process that converts such resources as labor and raw materials into goods and services that are sold to customers. >将劳动力或原材料等资源变成销售给顾客的最终产品和服务的转 换过程审的设计、运营和痊制。 The Importance of Operations Management ·运营管理的重要性 It encompasses both services and manufacturing >涵盖了服务业和制造业 It is important in effectively and efficiently managing productivity. >对于有效和高效率的管理生产非常重要 It plays a strategic role in an organization's competitive success. >对于组织进行成功的竞争具有战略作用 2007 Prentice Hall,Inc.All rights reserved. 19-4

© 2007 Prentice Hall, Inc. All rights reserved. 19–4 What Is Operations Management? 什么是运营管理 • Operations Management 运营管理 ➢ The design, operation, and control of the transformation process that converts such resources as labor and raw materials into goods and services that are sold to customers. ➢ 将劳动力或原材料等资源变成销售给顾客的最终产品和服务的转 换过程中的设计、运营和控制。 • The Importance of Operations Management • 运营管理的重要性 ➢ It encompasses both services and manufacturing. ➢ 涵盖了服务业和制造业 ➢ It is important in effectively and efficiently managing productivity. ➢ 对于有效和高效率的管理生产非常重要 ➢ It plays a strategic role in an organization’s competitive success. ➢ 对于组织进行成功的竞争具有战略作用

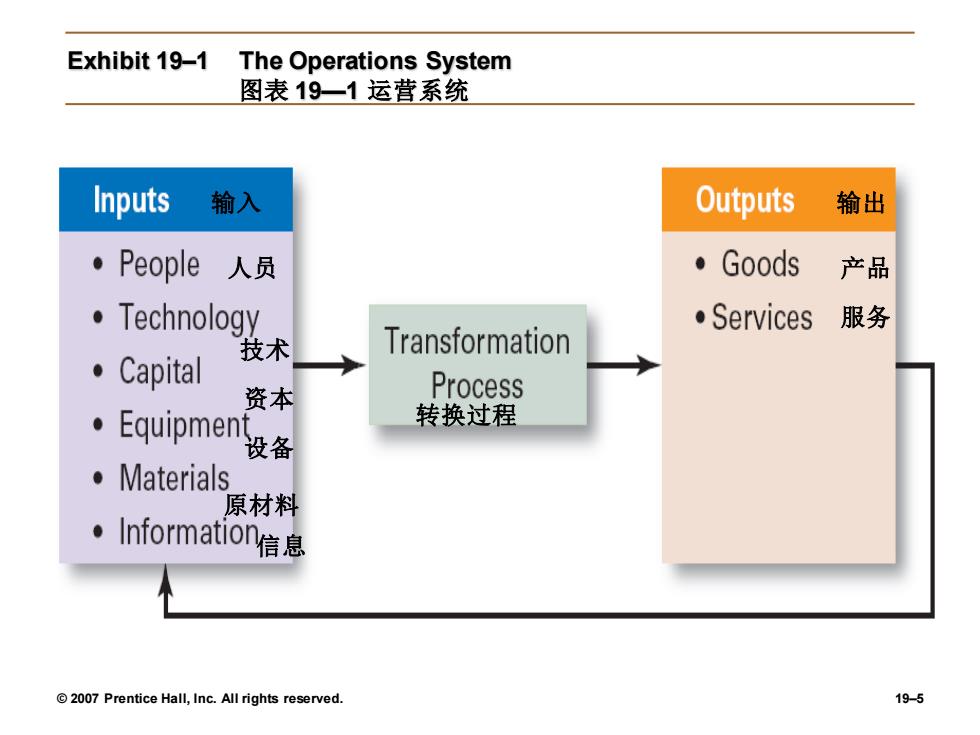

Exhibit 19-1 The Operations System 图表19一1运营系统 Inputs 输入 Outputs 输出 。People人员 ·G00ds 产品 ·Technology ·Services服务 技术 Transformation Capital 资本 Process 。 Equipmen 转换过程 设备 ·Material 原材料 。Information信息 2007 Prentice Hall,Inc.All rights reserved. 19-5

© 2007 Prentice Hall, Inc. All rights reserved. 19–5 Exhibit 19–1 The Operations System 图表 19—1 运营系统 输入 输出 人员 技术 资本 设备 原材料 信息 产品 服务 转换过程

Manufacturing and Services 服务业和制造业 ·Manufacturing Organizations制造型组织 >Use operations management in the transformation process of turning raw materials into physical goods >在转换过程运用运营管理将原材料转换为有形产品 ·Service Organizations服务型组织 Use operations management in creating nonphysical outputs in the form of services (the activities of employees interacting with customers). >将运营管理运用在以服务形式出现的无形输出中(员 工与顾客相互作用的活动) 2007 Prentice Hall,Inc.All rights reserved. 19-6

© 2007 Prentice Hall, Inc. All rights reserved. 19–6 Manufacturing and Services 服务业和制造业 • Manufacturing Organizations 制造型组织 ➢Use operations management in the transformation process of turning raw materials into physical goods. ➢在转换过程运用运营管理将原材料转换为有形产品 • Service Organizations 服务型组织 ➢Use operations management in creating nonphysical outputs in the form of services (the activities of employees interacting with customers). ➢将运营管理运用在以服务形式出现的无形输出中(员 工与顾客相互作用的活动)

Managing Productivity管理生产率 ·Productivity生产率 >The overall output of goods or services produced divided by the inputs needed to generate that output. >产出的所有产品和服务除以得到这些产出所需的全部收入 >A composite of people and operations variables. >一个由人员和运营组织组成的变量 Benefits of Increased Productivity ·提高生产率的好处 >Economic growth and development >经济增长与发展 >Higher wages and profits without inflation >更高的工资和利润并且没有通货膨胀 >Increased competitive capability due to lower costs >更具竞争力的成本结构和价格能力 2007 Prentice Hall,Inc.All rights reserved. 19-7

© 2007 Prentice Hall, Inc. All rights reserved. 19–7 Managing Productivity 管理生产率 • Productivity 生产率 ➢ The overall output of goods or services produced divided by the inputs needed to generate that output. ➢ 产出的所有产品和服务除以得到这些产出所需的全部收入 ➢ A composite of people and operations variables. ➢ 一个由人员和运营组织组成的变量 • Benefits of Increased Productivity • 提高生产率的好处 ➢ Economic growth and development ➢ 经济增长与发展 ➢ Higher wages and profits without inflation ➢ 更高的工资和利润并且没有通货膨胀 ➢ Increased competitive capability due to lower costs ➢ 更具竞争力的成本结构和价格能力

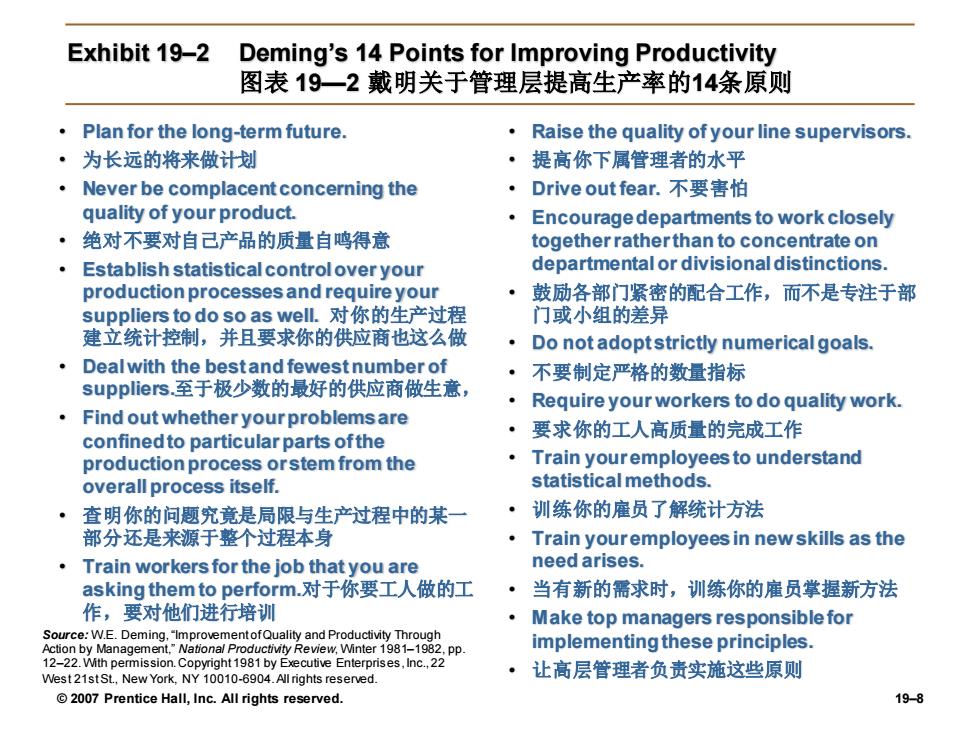

Exhibit 19-2 Deming's 14 Points for Improving Productivity 图表19一2戴明关于管理层提高生产率的14条原则 Plan for the long-term future. Raise the quality of your line supervisors. ·为长远的将来做计划 ·提高你下属管理者的水平 Never be complacentconcerning the ·Drive out fear.不要害怕 quality of your product. Encouragedepartments to work closely ·绝对不要对自己产品的质量自鸣得意 together ratherthan to concentrate on Establish statistical control over your departmental or divisional distinctions. production processes and require your 鼓励各部门紧密的配合工作,而不是专注于部 suppliers to do so as well.对你的生产过程 门或小组的差异 建立统计控制,并且要求你的供应商也这么做 Do not adoptstrictly numerical goals. Dealwith the bestand fewestnumber of ·不要制定严格的数量指标 suppliers.至于极少数的最好的供应商做生意, Require your workers to do quality work. Find out whether your problemsare ·要求你的工人高质量的完成工作 confined to particular parts ofthe production process orstem from the Train youremployeesto understand overall process itself. statistical methods. 查明你的问题究竟是局限与生产过程中的某一 ·训练你的雇员了解统计方法 部分还是来源于整个过程本身 Train youremployees in newskills as the Train workers for the job that you are need arises. asking them to perform.对于你要工人做的工 ·当有新的需求时,训练你的雇员掌握新方法 作,要对他们进行培训 Make top managers responsible for Source:W.E.Deming,"ImprovementofQuality and Productivity Through Action by Management.National Productivity Review.Winter191-1982.pp implementing these principles. 12-22.With pemission.Copyright1981 by Executive Enterprises.Inc.22 West 21stSt.,New York,NY 10010-6904.All rights reserved. ·让高层管理者负责实施这些原则 2007 Prentice Hall,Inc.All rights reserved. 19-8

© 2007 Prentice Hall, Inc. All rights reserved. 19–8 Exhibit 19–2 Deming’s 14 Points for Improving Productivity 图表 19—2 戴明关于管理层提高生产率的14条原则 • Plan for the long-term future. • 为长远的将来做计划 • Never be complacent concerning the quality of your product. • 绝对不要对自己产品的质量自鸣得意 • Establish statistical control over your production processes and require your suppliers to do so as well. 对你的生产过程 建立统计控制,并且要求你的供应商也这么做 • Deal with the best and fewest number of suppliers.至于极少数的最好的供应商做生意, • Find out whether your problems are confined to particular parts of the production process or stem from the overall process itself. • 查明你的问题究竟是局限与生产过程中的某一 部分还是来源于整个过程本身 • Train workers for the job that you are asking them to perform.对于你要工人做的工 作,要对他们进行培训 • Raise the quality of your line supervisors. • 提高你下属管理者的水平 • Drive out fear. 不要害怕 • Encourage departments to work closely together rather than to concentrate on departmental or divisional distinctions. • 鼓励各部门紧密的配合工作,而不是专注于部 门或小组的差异 • Do not adopt strictly numerical goals. • 不要制定严格的数量指标 • Require your workers to do quality work. • 要求你的工人高质量的完成工作 • Train your employees to understand statistical methods. • 训练你的雇员了解统计方法 • Train your employees in new skills as the need arises. • 当有新的需求时,训练你的雇员掌握新方法 • Make top managers responsible for implementing these principles. • 让高层管理者负责实施这些原则 Source: W.E. Deming, “Improvement of Quality and Productivity Through Action by Management,” National Productivity Review, Winter 1981–1982, pp. 12–22. With permission. Copyright 1981 by Executive Enterprises, Inc., 22 West 21st St., New York, NY 10010-6904. All rights reserved

Strategic Role of Operations Management 运作管理的战略作用 The era of modern manufacturing began in the U.S over 100 years ago. ·现代制造业起源于100年前的美国 After WWll,U.S.manufacturers'focused on functional areas other than manufacturing. ·在二战后,制造商开始关注其他职能领域而不是制造领域 By the 1970's,foreign competitors'integrated manufacturing technologies were producing quality goods at lower costs. ·到70年代末,外国竞争者提高制造技术,生产出低价高质的产品 U.S manufacturers responded by investing in updated technology, restructuring organizations,and including production requirements in their strategic planning. ·美国制造商做出反应,大量投资来改进制造技术,调整组织,将产品 需求融入到总体战略中 2007 Prentice Hall,Inc.All rights reserved. 19-9

© 2007 Prentice Hall, Inc. All rights reserved. 19–9 Strategic Role of Operations Management 运作管理的战略作用 • The era of modern manufacturing began in the U.S over 100 years ago. • 现代制造业起源于100年前的美国 • After WWII, U.S. manufacturers’ focused on functional areas other than manufacturing. • 在二战后,制造商开始关注其他职能领域而不是制造领域 • By the 1970’s, foreign competitors’ integrated manufacturing technologies were producing quality goods at lower costs. • 到70年代末,外国竞争者提高制造技术,生产出低价高质的产品 • U.S manufacturers responded by investing in updated technology, restructuring organizations, and including production requirements in their strategic planning. • 美国制造商做出反应,大量投资来改进制造技术,调整组织,将产品 需求融入到总体战略中

Value Chain Management 价值链管理 ·Value价值 The performance characteristics,features and attributes,and any other aspects of goods and services for which customers are willing to give up resources(i.e.,spend money). >行为的特征、特性和属性,以及顾客愿意放弃资源(通常是钱) 来换取的产品或服务的任何内容 ·The Value Chain价值链 The entire series of organizational work activities that add value at each step beginning with the processing of raw materials and ending with the finished product in the hands of end users. >就是从原材料加工到产成品到达最终顾客手中的过程中,所有增 加价值的步骤所组成的全部有组织的一系列活动 2007 Prentice Hall,Inc.All rights reserved. 19-10

© 2007 Prentice Hall, Inc. All rights reserved. 19–10 Value Chain Management 价值链管理 • Value 价值 ➢ The performance characteristics, features and attributes, and any other aspects of goods and services for which customers are willing to give up resources (i.e., spend money). ➢ 行为的特征、特性和属性,以及顾客愿意放弃资源(通常是钱) 来换取的产品或服务的任何内容 • The Value Chain 价值链 ➢ The entire series of organizational work activities that add value at each step beginning with the processing of raw materials and ending with the finished product in the hands of end users. ➢ 就是从原材料加工到产成品到达最终顾客手中的过程中,所有增 加价值的步骤所组成的全部有组织的一系列活动