Chapter 19 OPERATIONS DROB BI NS ACOULTER AND VALUE CHAIN MANAGEMENT ©Prentice Hall,2002 19-1

Chapter 19 OPERATIONS AND VALUE CHAIN MANAGEMENT © Prentice Hall, 2002 19-1

Learning Objectives You should learn to: -Describe the role of the transformation process in operations management Explain why operations management is important to all types of organizations Define value chain management Discuss the goal of value chain management Explain the organizational and managerial requirements for value chain management ©Prentice Hall,2002 19-2

Learning Objectives You should learn to: – Describe the role of the transformation process in operations management – Explain why operations management is important to all types of organizations – Define value chain management – Discuss the goal of value chain management – Explain the organizational and managerial requirements for value chain management © Prentice Hall, 2002 19-2

Learning Objectives (cont. You should learn to: Describe the benefits of and obstacles to value chain management Discuss technology's role in operations management Describe how quality affects operations management Explain ISO 9000 and Six Sigma ©Prentice Hall,2002 19-3

Learning Objectives (cont.) You should learn to: – Describe the benefits of and obstacles to value chain management – Discuss technology’s role in operations management – Describe how quality affects operations management – Explain ISO 9000 and Six Sigma © Prentice Hall, 2002 19-3

What Is Operations Management? Operations Management the design,operation,and control of the transformation process that converts such resources as labor and raw materials into goods and services that are sold to customers every organization has an operations system that creates value by transforming inputs into outputs every unit in an organization also has an operations system ©Prentice Hall,2002 19-4

What Is Operations Management? Operations Management – the design, operation, and control of the transformation process that converts such resources as labor and raw materials into goods and services that are sold to customers – every organization has an operations system that creates value by transforming inputs into outputs • every unit in an organization also has an operations system © Prentice Hall, 2002 19-4

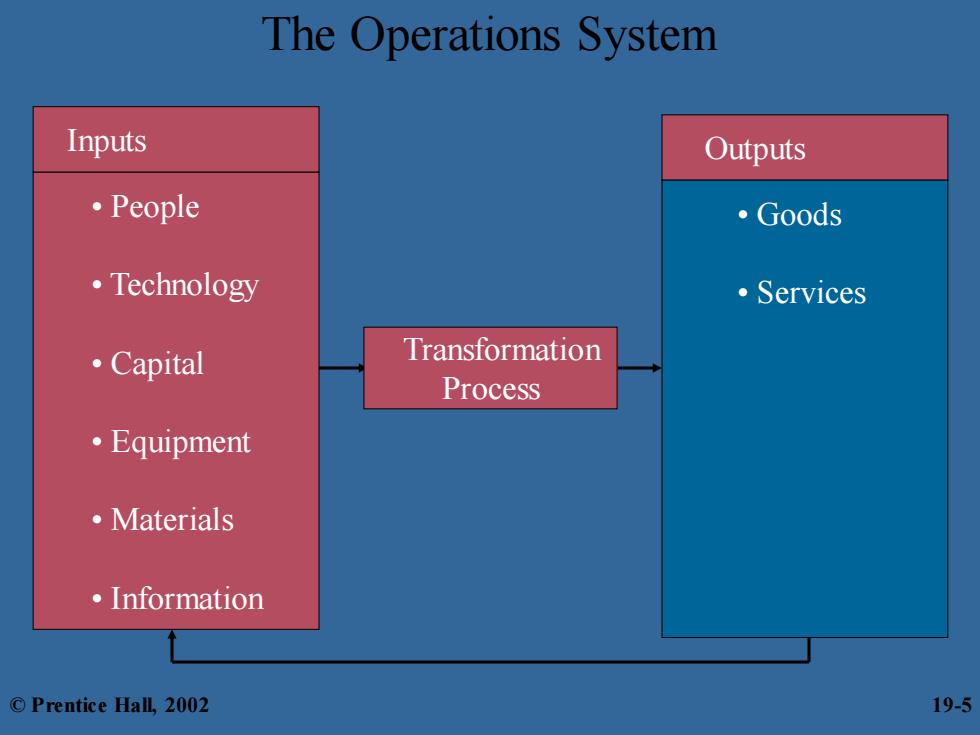

The Operations System Inputs Outputs ·People ·Goods ·Technology ·Services 。Capital Transformation Process ·Equipment ·Materials ·Information ©Prentice Hall,2002 19-5

The Operations System • People • Technology • Capital • Equipment • Materials • Information Inputs Outputs • Goods • Services Transformation Process © Prentice Hall, 2002 19-5

Why Is Operations Management Important? Encompasses Services and Manufacturing manufucturing organization-produces physical goods service organization-produces nonphysical outputs in the form of services U.S.economy currently dominated by the creation and sale of services Managing Productivity prodcv-overall output of goods or services divided by the inputs needed to generate that output increasing productivity is key to global competitiveness productivity is a composite of people and operations variables ©Prentice Hall,2002 19-6

Why Is Operations Management Important? Encompasses Services and Manufacturing – manufacturing organization - produces physical goods – service organization - produces nonphysical outputs in the form of services • U.S. economy currently dominated by the creation and sale of services Managing Productivity – productivity - overall output of goods or services divided by the inputs needed to generate that output – increasing productivity is key to global competitiveness – productivity is a composite of people and operations variables © Prentice Hall, 2002 19-6

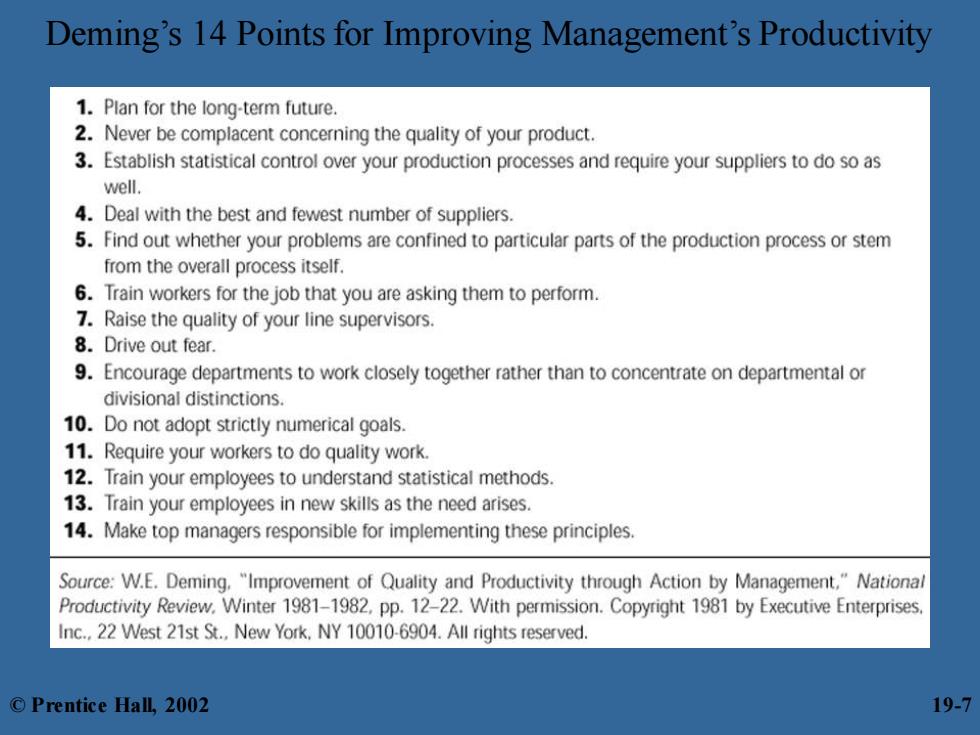

Deming's 14 Points for Improving Management's Productivity 1.Plan for the long-term future. 2.Never be complacent concerning the quality of your product. 3.Establish statistical control over your production processes and require your suppliers to do so as well. 4.Deal with the best and fewest number of suppliers. 5.Find out whether your problems are confined to particular parts of the production process or stem from the overall process itself. 6.Train workers for the job that you are asking them to perform. 7.Raise the quality of your line supervisors. 8.Drive out fear. 9.Encourage departments to work closely together rather than to concentrate on departmental or divisional distinctions. 10.Do not adopt strictly numerical goals. 11.Require your workers to do quality work. 12.Train your employees to understand statistical methods. 13.Train your employees in new skills as the need arises. 14.Make top managers responsible for implementing these principles. Source:W.E.Deming."Improvement of Quality and Productivity through Action by Management,"National Productivity Review.Winter 1981-1982.pp.12-22.With permission.Copyright 1981 by Executive Enterprises. Inc.22 West 21st St.New York.NY 10010-6904.All rights reserved. ©Prentice Hall,2002 19-7

Deming’s 14 Points for Improving Management’s Productivity © Prentice Hall, 2002 19-7

Importance Of Operations Management (cont. Strategic Role of Operations Management manufacturing operations taken for granted prior to1970 -in 1970s U.S.executives recognized that they were facing a crisis began incorporating existing and future production requirements into the organization's overall strategic plan ©Prentice Hall,2002 19-8

Importance Of Operations Management (cont.) Strategic Role of Operations Management – manufacturing operations taken for granted prior to 1970 – in 1970s U.S. executives recognized that they were facing a crisis • began incorporating existing and future production requirements into the organization’s overall strategic plan © Prentice Hall, 2002 19-8

Value Chain Management What is Value Chain Management? -vale-performance characteristics,features,and attributes,and any other aspects of goods and services for which customers are willing to give up resources organizations must provide value to attract and keep customers value provided through the transformation of raw materials into some product or service that end-users need where,when,and how they want it ©Prentice Hall,2002 19-9

Value Chain Management What is Value Chain Management? – value - performance characteristics, features, and attributes, and any other aspects of goods and services for which customers are willing to give up resources • organizations must provide value to attract and keep customers • value provided through the transformation of raw materials into some product or service that end-users need where, when, and how they want it © Prentice Hall, 2002 19-9

Value Chain Management (cont.) What is Value Chain Management?(cont.) valle chain entire series of work activities that add value at each step of the transformation process yalue chain management-process of managing an entire sequence of activities along the entire value chain is externally oriented -focuses on both incoming materials and outgoing products and services is effectiveness oriented and aims to create the highest value for customers supply chain management-is internally oriented ©Prentice Hall,2002 19-10

What is Value Chain Management? (cont.) – value chain - entire series of work activities that add value at each step of the transformation process – value chain management - process of managing an entire sequence of activities along the entire value chain • is externally oriented – focuses on both incoming materials and outgoing products and services • is effectiveness oriented and aims to create the highest value for customers – supply chain management - is internally oriented Value Chain Management (cont.) © Prentice Hall, 2002 19-10