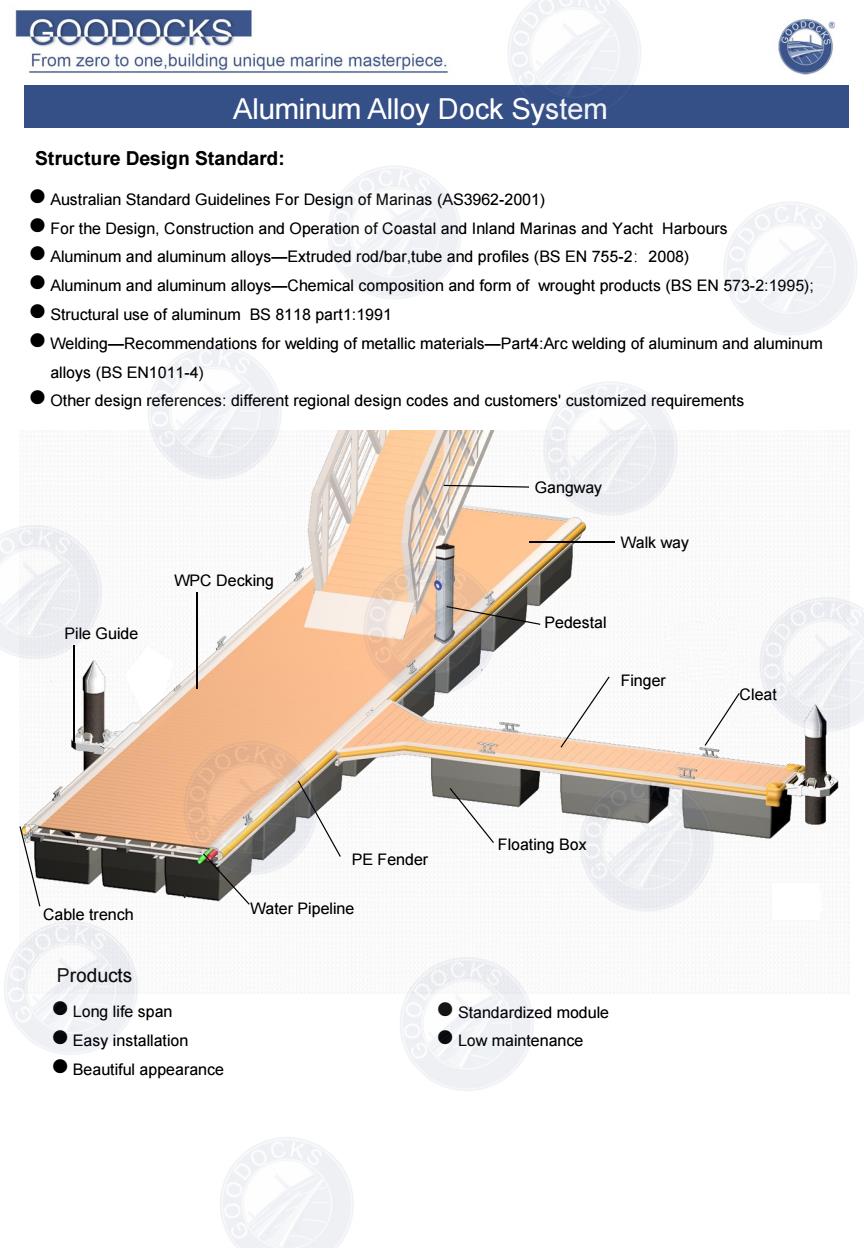

GOODOCKS From zero to one,building unique marine masterpiece. Aluminum Alloy Dock System Structure Design Standard: Australian Standard Guidelines For Design of Marinas(AS3962-2001) For the Design,Construction and Operation of Coastal and Inland Marinas and Yacht Harbours Aluminum and aluminum alloys-Extruded rod/bar,tube and profiles(BS EN 755-2:2008) Aluminum and aluminum alloys-Chemical composition and form of wrought products(BS EN 573-2:1995); Structural use of aluminum BS 8118 part1:1991 Welding-Recommendations for welding of metallic materials-Part4:Arc welding of aluminum and aluminum alloys(BS EN1011-4) Other design references:different regional design codes and customers'customized requirements Gangway Walk way WPC Decking Pedestal Pile Guide Finger Cleat Floating Box PE Fender Cable trench Water Pipeline Products ●Long life span ●Standardized module ●Easy installation ●Low maintenance OBeautiful appearance

Aluminum Alloy Dock System Products l Long life span l Easy installation l Beautiful appearance l Standardized module l Low maintenance cost Walk way l Australian Standard Guidelines For Design of Marinas (AS3962-2001) l For the Design, Construction and Operation of Coastal and Inland Marinas and Yacht Harbours l Aluminum and aluminum alloys—Extruded rod/bar,tube and profiles (BS EN 755-2:2008) l Aluminum and aluminum alloys—Chemical composition and form of wrought products (BS EN 573-2:1995); l Structural use of aluminum BS 8118 part1:1991 l Welding—Recommendations for welding of metallic materials—Part4:Arc welding of aluminum and aluminum alloys (BS EN1011-4) l Other design references: different regional design codes and customers' customized requirements Structure Design Standard: Gangway Cleat PE Fender Water Pipeline Finger Cable trench Pile Guide Pedestal Floating Box WPC Decking

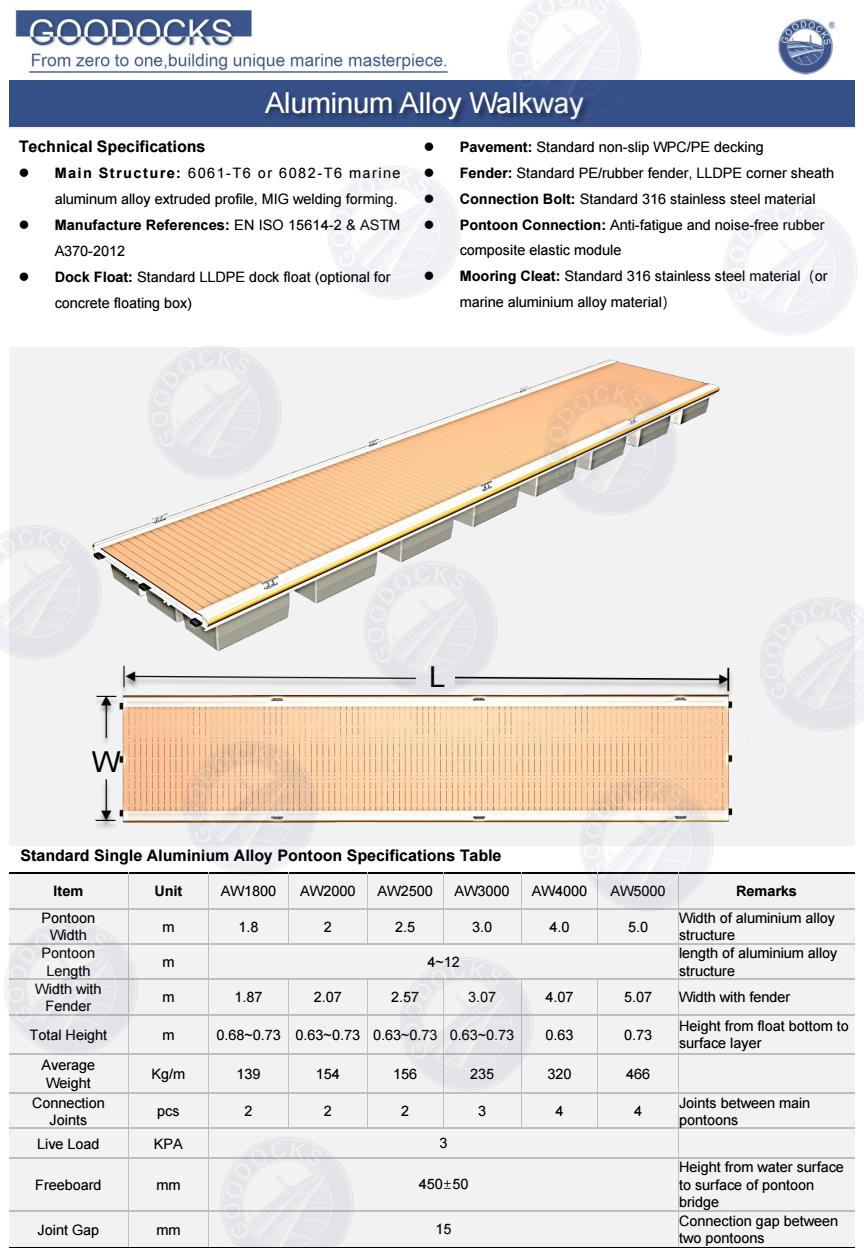

GOODOCKS From zero to one,building unique marine masterpiece Aluminum Alloy Walkway Technical Specifications ● Pavement:Standard non-slip WPC/PE decking ● Main Structure:6061-T6 or 6082-T6 marine ● Fender:Standard PE/rubber fender.LLDPE corner sheath aluminum alloy extruded profile,MIG welding forming. ● Connection Bolt:Standard 316 stainless steel material ● Manufacture References:EN ISO 15614-2 ASTM Pontoon Connection:Anti-fatigue and noise-free rubber A370-2012 composite elastic module ● Dock Float:Standard LLDPE dock float (optional for Mooring Cleat:Standard 316 stainless steel material (or concrete floating box) marine aluminium alloy material) W Standard Single Aluminium Alloy Pontoon Specifications Table Item Unit AW1800 AW2000 AW2500 AW3000 AW4000 AW5000 Remarks Pontoon Width of aluminium alloy Width m 1.8 2 2.5 3.0 4.0 5.0 structure Pontoon m 4-12 length of aluminium alloy Length structure Width with m 1.87 2.07 2.57 3.07 4.07 Fender 5.07 Width with fender Total Height Height from float bottom to m 0.68-0.73 0.63-0.73 0.63-0.730.63-0.73 0.63 0.73 surface layer Average Weight Kg/m 139 154 156 235 320 466 Connection pcs 2 2 2 3 4 Joints between main 4 Joints pontoons Live Load KPA 3 Height from water surface Freeboard mm 450±50 to surface of pontoon bridge Joint Gap Connection gap between mm 15 two pontoons

L W Standard Single Aluminium Alloy Pontoon Specifications Table Item Unit AW1800 AW2000 AW2500 AW3000 AW4000 AW5000 Remarks Pontoon Width m 1.8 2 2.5 3.0 4.0 5.0 Width of aluminium alloy structure Pontoon Length m 4~12 length of aluminium alloy structure Width with Fender m 1.87 2.07 2.57 3.07 4.07 5.07 Width with fender Total Height m 0.68~0.73 0.63~0.73 0.63~0.73 0.63~0.73 0.63 0.73 Height from float bottom to surface layer Average Weight Kg/m 139 154 156 235 320 466 Connection Joints pcs 2 2 2 3 4 4 Joints between main pontoons Live Load KPA 3 Freeboard mm 450±50 Height from water surface to surface of pontoon bridge Joint Gap mm 15 Connection gap between two pontoons Aluminum Alloy Walkway Technical Specifications l Main Structure: 6061-T6 or 6082-T6 marine aluminum alloy extruded profile, MIG welding forming. l Manufacture References: EN ISO 15614-2 & ASTM A370-2012 l Dock Float: Standard LLDPE dock float (optional for concrete floating box) l Pavement: Standard non-slip WPC/PE decking l Fender: Standard PE/rubber fender, LLDPE corner sheath l Connection Bolt: Standard 316 stainless steel material l Pontoon Connection: Anti-fatigue and noise-free rubber composite elastic module l Mooring Cleat: Standard 316 stainless steel material(or marine aluminium alloy material)

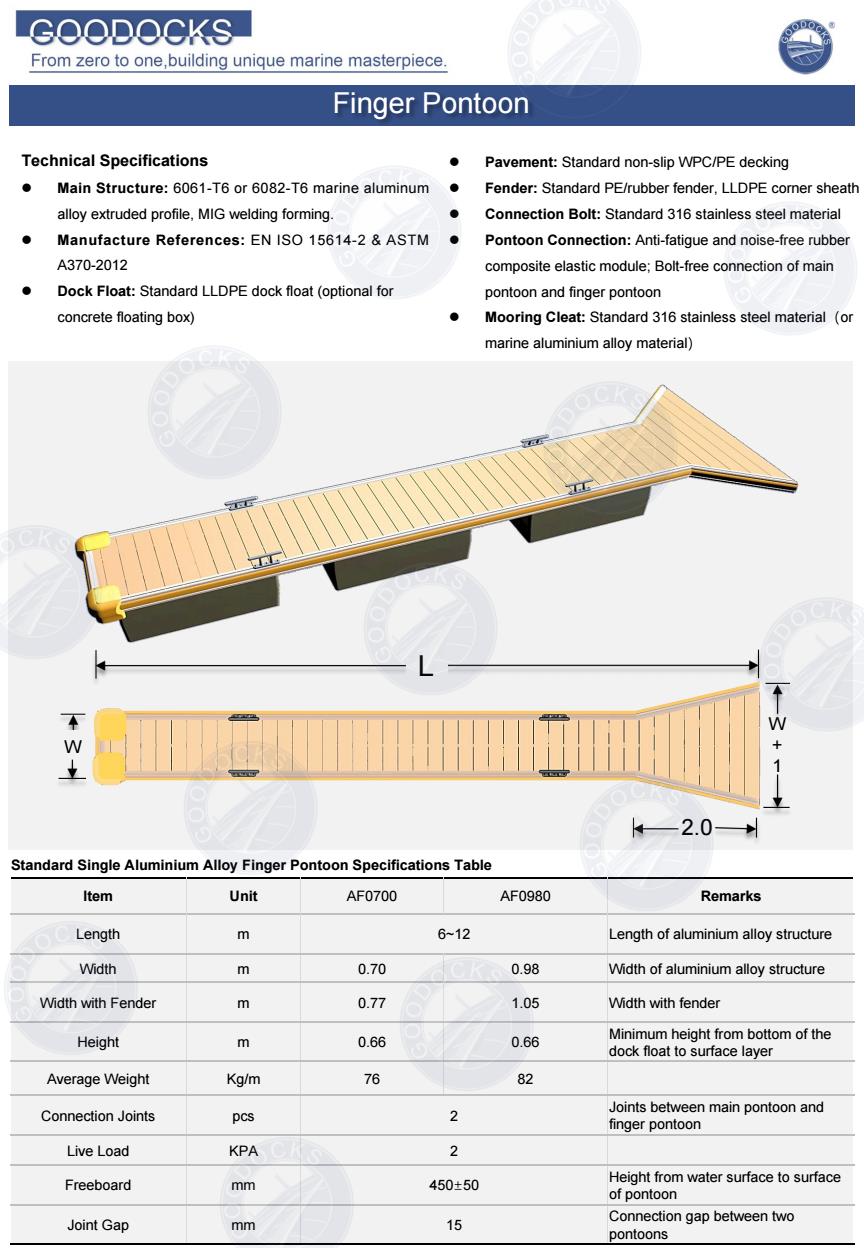

GOODOCKS From zero to one,building unique marine masterpiece. Finger Pontoon Technical Specifications ● Pavement:Standard non-slip WPC/PE decking ● Main Structure:6061-T6 or 6082-T6 marine aluminum ● Fender:Standard PE/rubber fender.LLDPE corner sheath alloy extruded profile,MIG welding forming. ● Connection Bolt:Standard 316 stainless steel material ● Manufacture References:EN ISO 15614-2 ASTM ● Pontoon Connection:Anti-fatique and noise-free rubber A370-2012 composite elastic module:Bolt-free connection of main ● Dock Float:Standard LLDPE dock float(optional for pontoon and finger pontoon concrete floating box) ● Mooring Cleat:Standard 316 stainless steel material (or marine aluminium alloy material) W —2.0+ Standard Single Aluminium Alloy Finger Pontoon Specifications Table Item Unit AF0700 AF0980 Remarks Length m 6-12 Length of aluminium alloy structure Width m 0.70 0.98 Width of aluminium alloy structure Width with Fender m 0.77 1.05 Width with fender Height m 0.66 0.66 Minimum height from bottom of the dock float to surface layer Average Weight Kg/m 76 82 Connection Joints pcs 2 Joints between main pontoon and finger pontoon Live Load KPA 2 Freeboard 450±50 Height from water surface to surface mm of pontoon Joint Gap mm 15 Connection gap between two pontoons

Finger Pontoon Standard Single Aluminium Alloy Finger Pontoon Specifications Table Item Unit AF0700 AF0980 Remarks Length m 6~12 Length of aluminium alloy structure Width m 0.70 0.98 Width of aluminium alloy structure Width with Fender m 0.77 1.05 Width with fender Height m 0.66 0.66 Minimum height from bottom of the dock float to surface layer Average Weight Kg/m 76 82 Connection Joints pcs 2 Joints between main pontoon and finger pontoon Live Load KPA 2 Freeboard mm 450±50 Height from water surface to surface of pontoon Joint Gap mm 15 Connection gap between two pontoons L W + 1 2.0 W Technical Specifications l Main Structure: 6061-T6 or 6082-T6 marine aluminum alloy extruded profile, MIG welding forming. l Manufacture References: EN ISO 15614-2 & ASTM A370-2012 l Dock Float: Standard LLDPE dock float (optional for concrete floating box) l Pavement: Standard non-slip WPC/PE decking l Fender: Standard PE/rubber fender, LLDPE corner sheath l Connection Bolt: Standard 316 stainless steel material l Pontoon Connection: Anti-fatigue and noise-free rubber composite elastic module; Bolt-free connection of main pontoon and finger pontoon l Mooring Cleat: Standard 316 stainless steel material(or marine aluminium alloy material)

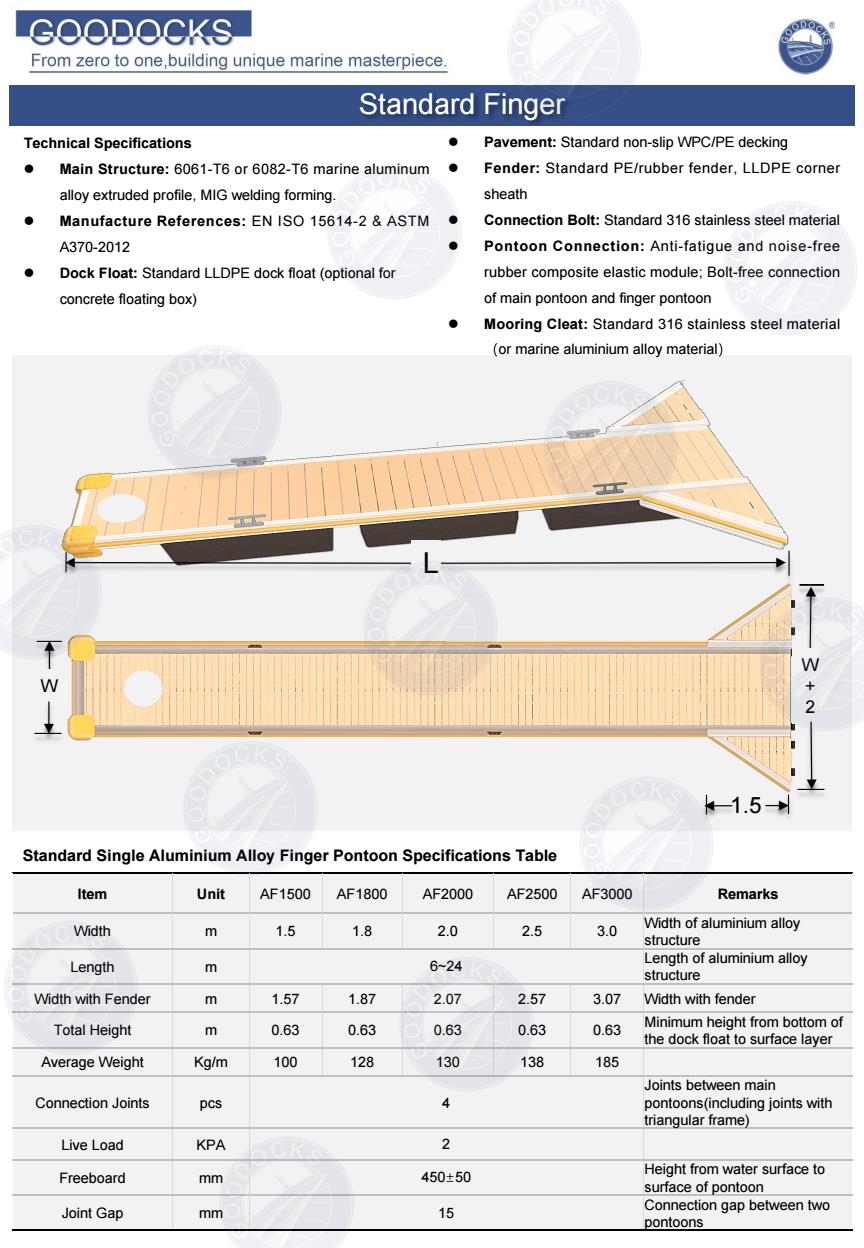

GOODOCKS From zero to one,building unique marine masterpiece. Standard Finger Technical Specifications ● Pavement:Standard non-slip WPC/PE decking ● Main Structure:6061-T6 or 6082-T6 marine aluminum ● Fender:Standard PE/rubber fender,LLDPE corner alloy extruded profile,MIG welding forming. sheath ● Manufacture References:EN ISO 15614-2 ASTM Connection Bolt:Standard 316 stainless steel material A370-2012 ● Pontoon Connection:Anti-fatigue and noise-free Dock Float:Standard LLDPE dock float (optional for rubber composite elastic module:Bolt-free connection concrete floating box) of main pontoon and finger pontoon ● Mooring Cleat:Standard 316 stainless steel material (or marine aluminium alloy material) -1.5 Standard Single Aluminium Alloy Finger Pontoon Specifications Table Item Unit AF1500 AF1800 AF2000 AF2500 AF3000 Remarks Width m 1.5 1.8 2.0 2.5 3.0 Width of aluminium alloy structure Length m 6-24 Length of aluminium alloy structure Width with Fender m 1.57 1.87 2.07 2.57 3.07 Width with fender Total Height m 0.63 0.63 0.63 0.63 0.63 Minimum height from bottom of the dock float to surface layer Average Weight Kg/m 100 128 130 138 185 Joints between main Connection Joints pcs pontoons(including joints with triangular frame) Live Load KPA 2 Freeboard 450±50 Height from water surface to mm surface of pontoon Joint Gap mm 15 Connection gap between two pontoons

Standard Finger Standard Single Aluminium Alloy Finger Pontoon Specifications Table Item Unit AF1500 AF1800 AF2000 AF2500 AF3000 Remarks Width m 1.5 1.8 2.0 2.5 3.0 Width of aluminium alloy structure Length m 6~24 Length of aluminium alloy structure Width with Fender m 1.57 1.87 2.07 2.57 3.07 Width with fender Total Height m 0.63 0.63 0.63 0.63 0.63 Minimum height from bottom of the dock float to surface layer Average Weight Kg/m 100 128 130 138 185 Connection Joints pcs 4 Joints between main pontoons(including joints with triangular frame) Live Load KPA 2 Freeboard mm 450±50 Height from water surface to surface of pontoon Joint Gap mm 15 Connection gap between two pontoons L W + 2 1.5 W Technical Specifications l Main Structure: 6061-T6 or 6082-T6 marine aluminum alloy extruded profile, MIG welding forming. l Manufacture References: EN ISO 15614-2 & ASTM A370-2012 l Dock Float: Standard LLDPE dock float (optional for concrete floating box) l Pavement: Standard non-slip WPC/PE decking l Fender: Standard PE/rubber fender, LLDPE corner sheath l Connection Bolt: Standard 316 stainless steel material l Pontoon Connection: Anti-fatigue and noise-free rubber composite elastic module; Bolt-free connection of main pontoon and finger pontoon l Mooring Cleat: Standard 316 stainless steel material (or marine aluminium alloy material)

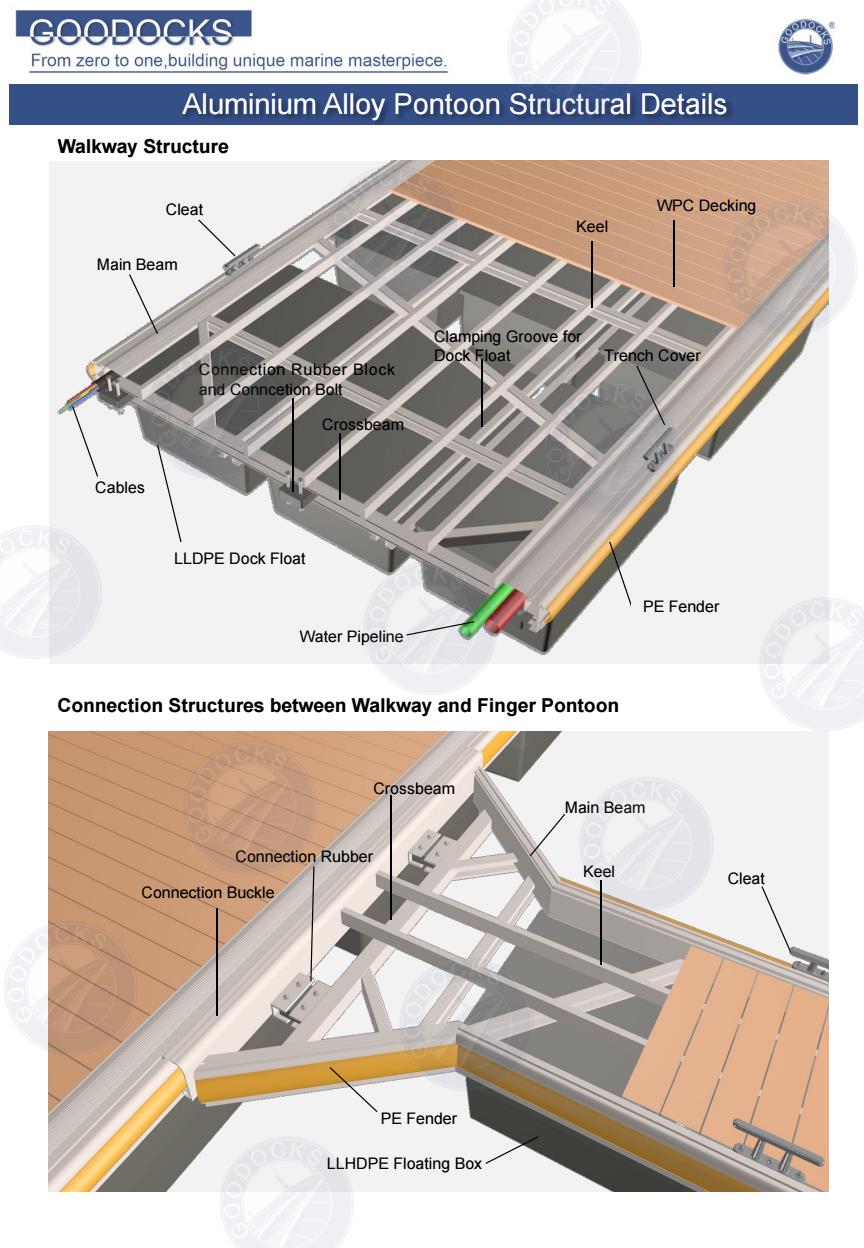

GOODOCKS From zero to one,building unique marine masterpiece. Aluminium Alloy Pontoon Structural Details Walkway Structure Cleat WPC Decking Keel Main Beam Clamping Groove for Dock Float Trench Cover Connection Rubber Block and Conncetion Bolt Crossbeam Cables LLDPE Dock Float PE Fender Water Pipeline Connection Structures between Walkway and Finger Pontoon Crossbeam Main Beam Connection Rubber Keel Cleat Connection Buckle PE Fender LLHDPE Floating Box

Aluminium Alloy Pontoon Structural Details Walkway Structure Connection Structures between Walkway and Finger Pontoon PE Fender LLHDPE Floating Box Cleat Main Beam Connection Rubber Connection Buckle Keel Crossbeam Water Pipeline Cables LLDPE Dock Float PE Fender Cleat Trench Cover Main Beam Keel Crossbeam Connection Rubber Block and Conncetion Bolt Clamping Groove for Dock Float WPC Decking

GOODOCKS From zero to one,building unique marine masterpiece. Triangular Frame Tripod Structure Frame on Finger Pontoon: Tripod structure:6061-T6 or 6082-T6 maritime aluminum alloy extruded profile,tripod and finger pontoon are integrally welded and MIG welded. ● The manufacturing process conforms to the standards of EN ISO 15614-2 and ASTM A370- 2012. Paving:WPC non-slip plastic wood floor Fender:PE fender is standard(or rubber fender is optional) ● Bolt:316 stainless steel. ● Bolt-free connection between tripod and main bridge. Standard Tripod Structure Frame on Finger Pontoon: Tripod structure:6061-T6 or 6082-T6 maritime aluminum alloy extruded profile,tripod and finger pontoon are integrally welded and MIG welded. .The manufacturing process conforms to the standards of EN ISO 15614-2 and ASTM A370-2012. Paving:WPC non-slip plastic wood floor. Fender:PE fender is standard(or rubber fender is optional) Bolt:316 stainless steel. ● Bolt-free connection between tripod and main bridge. Tripod Structure Frame on Finger Pontoon Standard Tripod Structure Frame on Finger Pontoon Item Unit TF0520 Remarks Item Unit TF1515 TF1015 Remarks Length m 2.0 Length m 1.5 1.5 Width m 0.5 Width m 1.5 1.0 Height mm 198 Height of bevel edge Height mm 218 218 Height of bevel edge Average Weight Kg/pcs 29 Average Weight Kg/pcs 38 35 Joints between main Joints between Connection Connection pcs 1 pontoon and finger pcs 1 Joints main pontoon and Joints pontoon finger pontoon Joints Gap mm 15 Joints gap between two pontoons Joints Gap mm 15 Joints gap between two pontoons

Triangular Frame 主体结构: l 浮桥主结构:6061-T6或6082-T6海事铝合金挤压型 材,MIG焊接成型。 l 制造工艺符合 CSA W47.2 和 ANSI/AWS D1.2 标准。 l 浮箱:标配PE浮箱(可选混凝土浮箱)。 l 铺板:WPC防滑塑木地板及PE防滑地板。 Tripod Structure Frame on Finger Pontoon: l Tripod structure: 6061-T6 or 6082-T6 maritime aluminum alloy extruded profile, tripod and finger pontoon are integrally welded and MIG welded. l The manufacturing process conforms to the standards of EN ISO 15614-2 and ASTM A370- 2012. l Paving: WPC non-slip plastic wood floor. l Fender: PE fender is standard (or rubber fender is optional) l Bolt: 316 stainless steel. l Bolt-free connection between tripod and main bridge. l Standard Tripod Structure Frame on Finger Pontoon: l Tripod structure: 6061-T6 or 6082-T6 maritime aluminum alloy extruded profile, tripod and finger pontoon are integrally welded and MIG welded. l The manufacturing process conforms to the standards of EN ISO 15614-2 and ASTM A370-2012. l Paving: WPC non-slip plastic wood floor. l Fender: PE fender is standard (or rubber fender is optional) l Bolt: 316 stainless steel. l Bolt-free connection between tripod and main bridge. Tripod Structure Frame on Finger Pontoon Item Unit TF0520 Remarks Length m 2.0 Width m 0.5 Height mm 198 Height of bevel edge Average Weight Kg/pcs 29 Connection Joints pcs 1 Joints between main pontoon and finger pontoon Joints Gap mm 15 Joints gap between two pontoons Standard Tripod Structure Frame on Finger Pontoon Item Unit TF1515 TF1015 Remarks Length m 1.5 1.5 Width m 1.5 1.0 Height mm 218 218 Height of bevel edge Average Weight Kg/pcs 38 35 Connection Joints pcs 1 Joints between main pontoon and finger pontoon Joints Gap mm 15 Joints gap between two pontoons

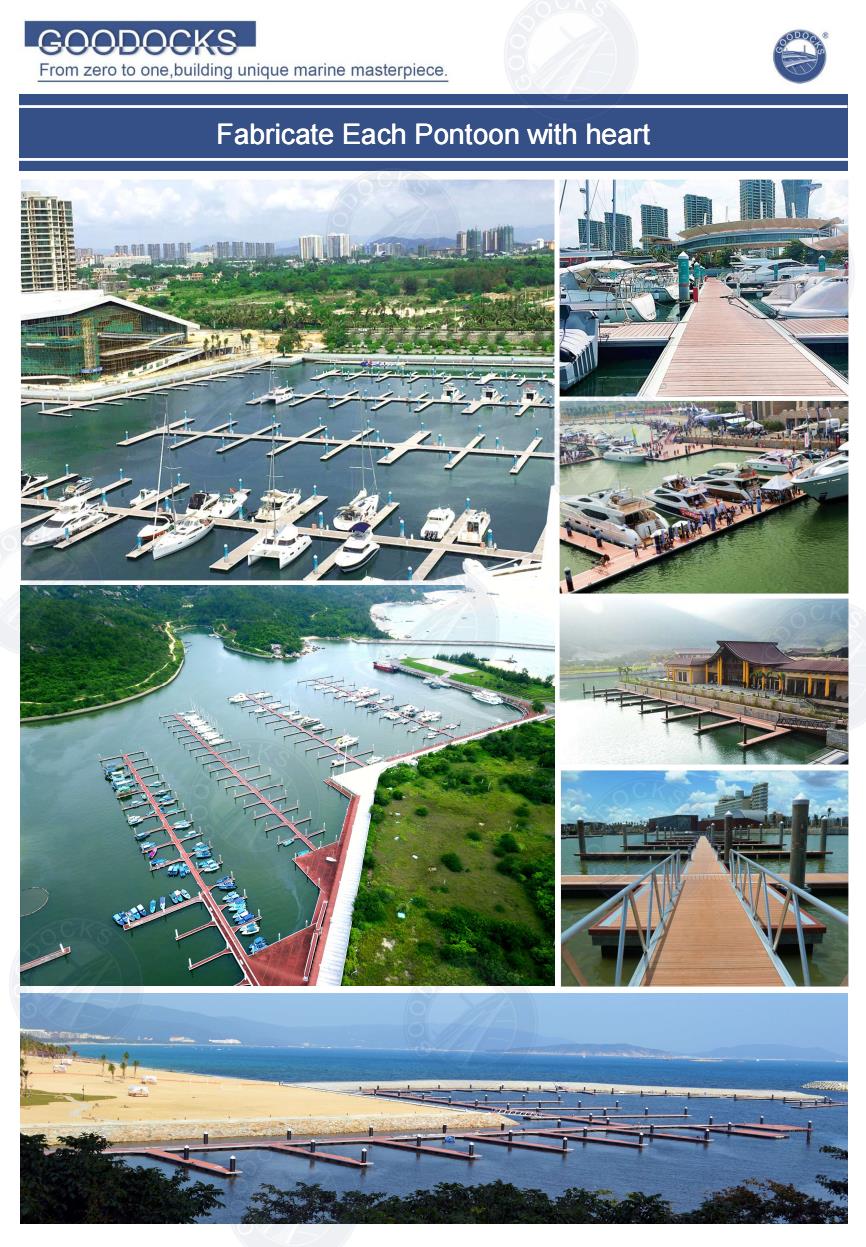

GOODOCKS From zero to one,building unique marine masterpiece. Fabricate Each Pontoon with heart B2的

Fabricate Each Pontoon with heart