2018/3/11 圆上活大学 Overview of Lectures 国上清大学 0.Overview 14/15 Performance(a,b) 1.Introduction 16.Aircraft certification 2.Overall configuration (a,b) 17 Aviation economics 3.Preliminary weight estimation 18.Svstem integration and Aircraft Design 4.Refined weight estimation confiquration management 5.Fuselage design (飞行器设计) 6.Aerodynamic design(a,b) 9.Thrust/Weight ratio and wing loading0.Military aircraft design- 10.Landing gear and Aircraft systems overview 21.Environmental issues 11.Power plant Wenbin Song 12.Stability and control 22.Design skills School of Aeronautics and Astronautics 13.Loads,materials and structures oorornenin ong Content 国上活美大坐 International Standard Atmosphere (ISA) 圆上清道大坐 Aerodynamic Design (2) An atmospheric model of how pressure,density,temperature,and Airfoil viscosity relate to altitudes (ISO 2533:1975) -Wing ·Basic law -Fuselage -Tail Ge etry Buoyancy Equation Aerodynamic Forces and Moments (2) ·Troposphere -Lift Estimation -Drag Estimation -Moment Estimation (not included Stratosphere (Temperature Constant,about 10-50km) CFD-based aerodynamic shape design (2) netry Param terization 2=e 卫-★ -CFD Sim lation % Reverse Design and Numerical Optimization Sea-level data 4-1SC五-23.150A-1225k1we-340294eh&-0665R-270527J-g.k 3 oerandenn ong 4 ISA Data Chart 国上洋大坐 Topics Covered 园上海发大坐 1.000 ·t Clean configuration -Effect of high lift devices on aero coefficients 0.80 ·Dag a70 -Drag breakdown-according to physical mechanisms form drag friction drag wave drag 0.500 Drag breakdown-component based 0500 ·Use of form factors Trim drag 0.400 ·Methods and software 0.3000 DATCOM,ESDU 02800 -Coding it yourselr 0.000 0 5000 10000 15000 30a0 Shanghal Jlao Tong Universty-Dr.Wenbin Song rslty-Dr.V(enbin Song 1

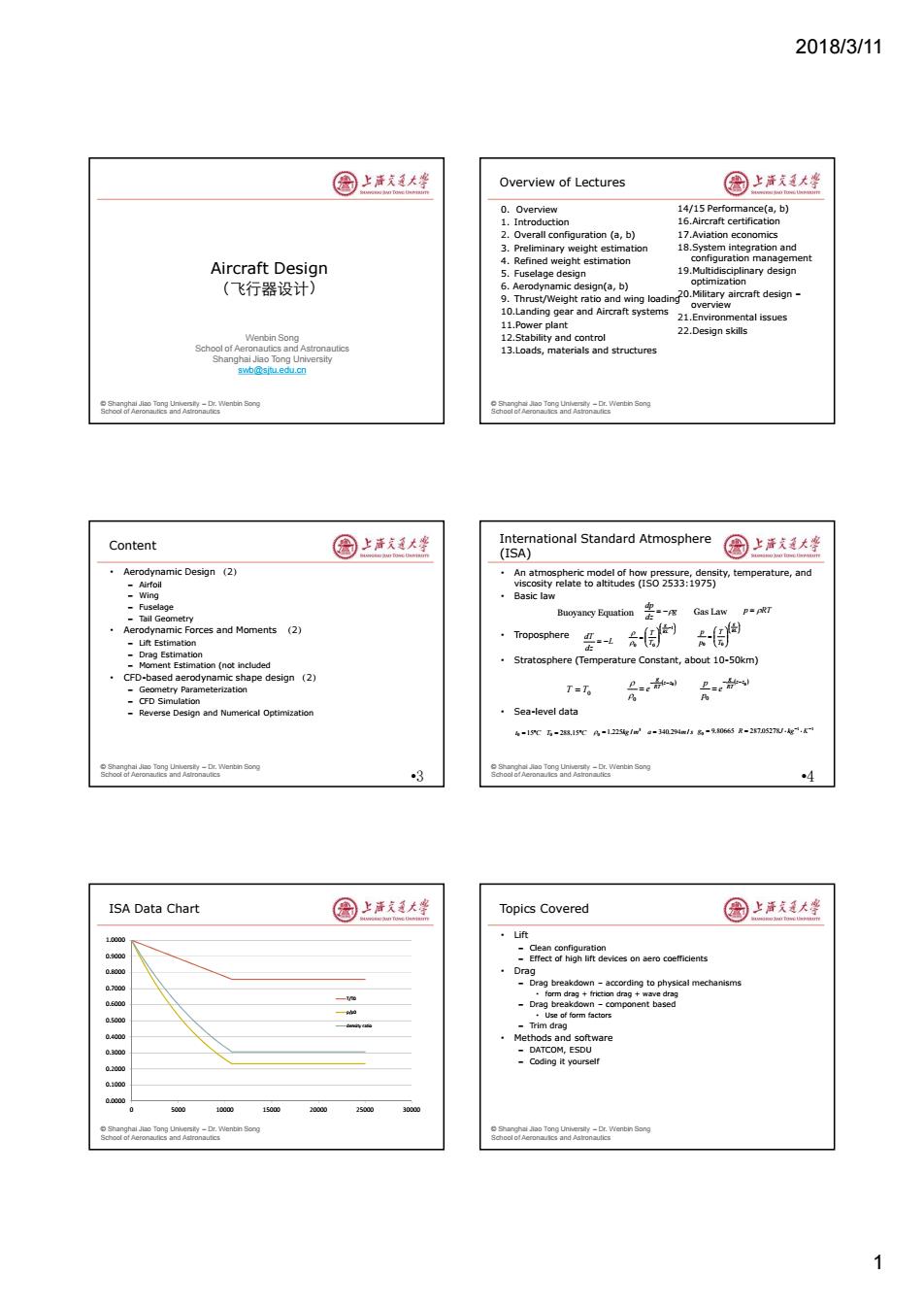

2018/3/11 1 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Wenbin Song School of Aeronautics and Astronautics Shanghai Jiao Tong University swb@sjtu.edu.cn Aircraft Design (飞行器设计) © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Overview of Lectures 0. Overview 1. Introduction 2. Overall configuration (a, b) 3. Preliminary weight estimation 4. Refined weight estimation 5. Fuselage design 6. Aerodynamic design(a, b) 9. Thrust/Weight ratio and wing loading 10.Landing gear and Aircraft systems 11.Power plant 12.Stability and control 13.Loads, materials and structures 14/15 Performance(a, b) 16.Aircraft certification 17.Aviation economics 18.System integration and configuration management 19.Multidisciplinary design optimization 20.Military aircraft design – overview 21.Environmental issues 22.Design skills © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Content • Aerodynamic Design (2) – Airfoil – Wing – Fuselage – Tail Geometry • Aerodynamic Forces and Moments (2) – Lift Estimation – Drag Estimation – Moment Estimation (not included • CFD-based aerodynamic shape design (2) – Geometry Parameterization – CFD Simulation – Reverse Design and Numerical Optimization •3 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics International Standard Atmosphere (ISA) • An atmospheric model of how pressure, density, temperature, and viscosity relate to altitudes (ISO 2533:1975) • Basic law • Troposphere • Stratosphere (Temperature Constant, about 10-50km) • Sea-level data •4 g dz dp Buoyancy Equation Gas Law p RT L dz dT 1 0 0 RL g T T RL g T T p p 0 0 0 0 z z RT g e 0 0 z z RT g e p p T T0 t0 15C T0 288.15C 3 0 1.225kg / m a 340.294m/s g0 9.80665 1 1 287.05278 R J kg K © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics ISA Data Chart 0.0000 0.1000 0.2000 0.3000 0.4000 0.5000 0.6000 0.7000 0.8000 0.9000 1.0000 0 5000 10000 15000 20000 25000 30000 T/T0 p/p0 density ratio © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Topics Covered • Lift – Clean configuration – Effect of high lift devices on aero coefficients • Drag – Drag breakdown – according to physical mechanisms • form drag + friction drag + wave drag – Drag breakdown – component based • Use of form factors – Trim drag • Methods and software – DATCOM, ESDU – Coding it yourself

2018/3/11 Origins of Aerodynamic Forces 图上活大学 Factors that influence aerodynamic forces 国上清大学 Shear forces->skin friction drag Geometry Pressure difference.>lift,pressure drag Surface roughness Supersonic flight->wave drag ·Flight speed Altitude(air density,temperature,pressure) 。Reynolds Number(Re) SHEAR MOLECULES Wind tunnel -CFD (numerical wing tunnel) O是ZTw保s.OUTWARDO oorn enin Song 圆上清文大些 Lift 圆上洋文廷大蜂 Lift-Aerodynamic force perpendicular to the flow direction 地m业c.G-(侷) CL-essentially linear before reaching the stall angle For setting the wing incidence angle Section B-1 For calculatingdrag-due-to lift AERODYNAMIC FORCES-LIFT -For longitudinalstability analysis For cruise condition,the lift requirement can be calculated from CL=L/q Srer =W/gSrer nwentin ong Effect of Camber and AR on CLa 圈上洋文通大坐 Subsonic Lift-Curve Slope 园上海发大坐 2元A EFFECT OF CAMBER EFFECT OF ASPECT RATIO CLa=- 2+ B ASPECT RATIO 4+ l+tan2 3 B2 where B2=1-M2 7= C 2π/ airfoil efficiency (o.95) fuselage lift factor F=min(1.071+d/b)2,0.98) Wing effective aspect ratio Aegecme =4(1+1.9h/b)Endplate due to wing tip modifications Aee≈l.2 Winglet A is the geometric aspect ratio of the complete reference wing ry-ur.wwennn song 2

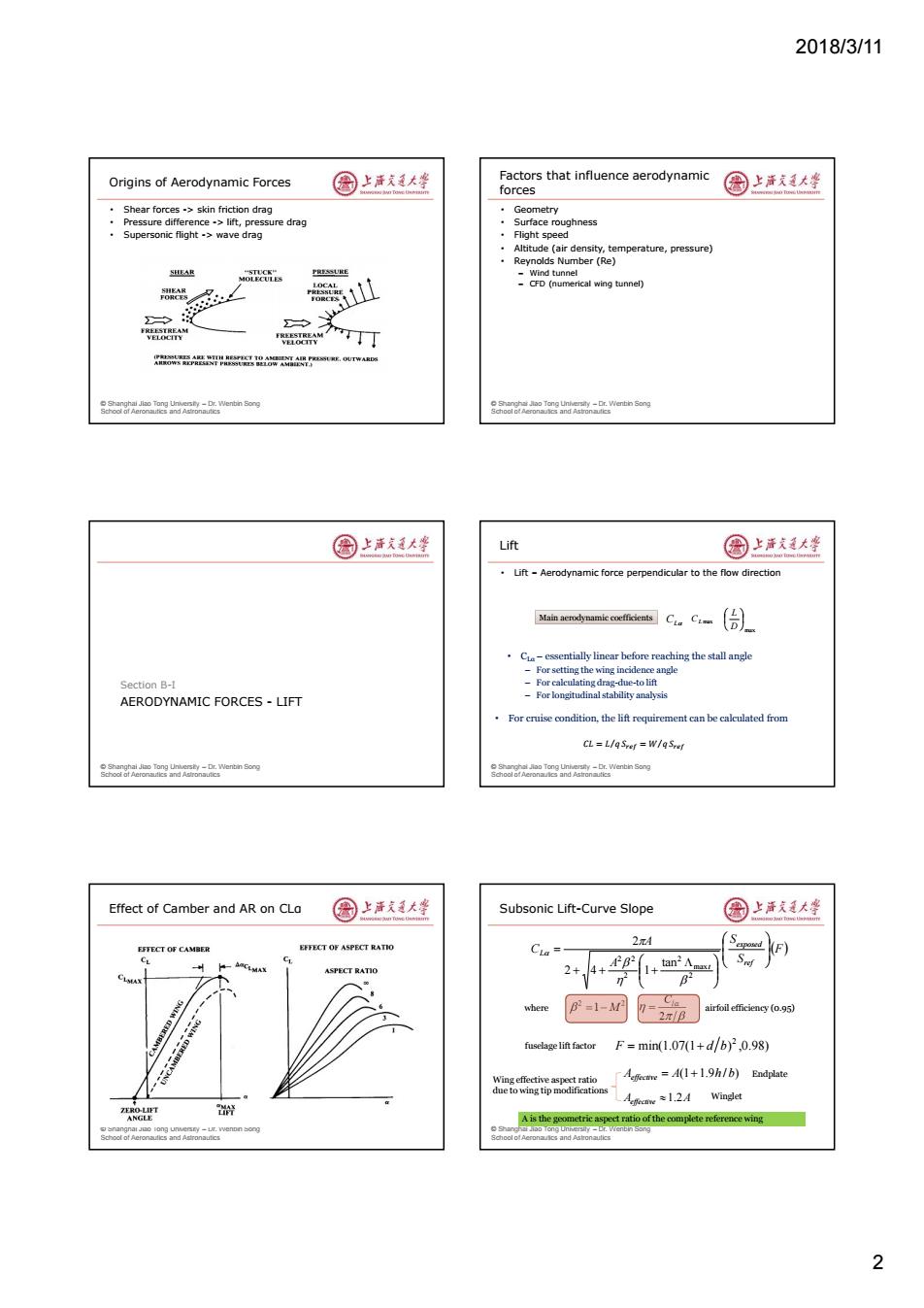

2018/3/11 2 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Origins of Aerodynamic Forces • Shear forces -> skin friction drag • Pressure difference -> lift, pressure drag • Supersonic flight -> wave drag © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Factors that influence aerodynamic forces • Geometry • Surface roughness • Flight speed • Altitude (air density, temperature, pressure) • Reynolds Number (Re) – Wind tunnel – CFD (numerical wing tunnel) © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics AERODYNAMIC FORCES - LIFT Section B-I © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Lift • Lift – Aerodynamic force perpendicular to the flow direction CL Main aerodynamic coefficients CL max max D L • CLα – essentially linear before reaching the stall angle – For setting the wing incidence angle – For calculating drag-due-to lift – For longitudinal stability analysis 𝐶𝐿 = 𝐿 𝑞⁄ 𝑆 = 𝑊 𝑞⁄ 𝑆 • For cruise condition, the lift requirement can be calculated from © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Effect of Camber and AR on CLα © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Subsonic Lift-Curve Slope F S S A A C ref exposed t L 2 max 2 2 2 2 tan 2 4 1 2 2 2 1 M 2 Cl where airfoil efficiency (0.95) fuselage lift factor min(1.07(1 ) ,0.98) 2 F d b A A(1 1.9h / b) effective Aeffective 1.2A Endplate Winglet Wing effective aspect ratio due to wing tip modifications A is the geometric aspect ratio of the complete reference wing

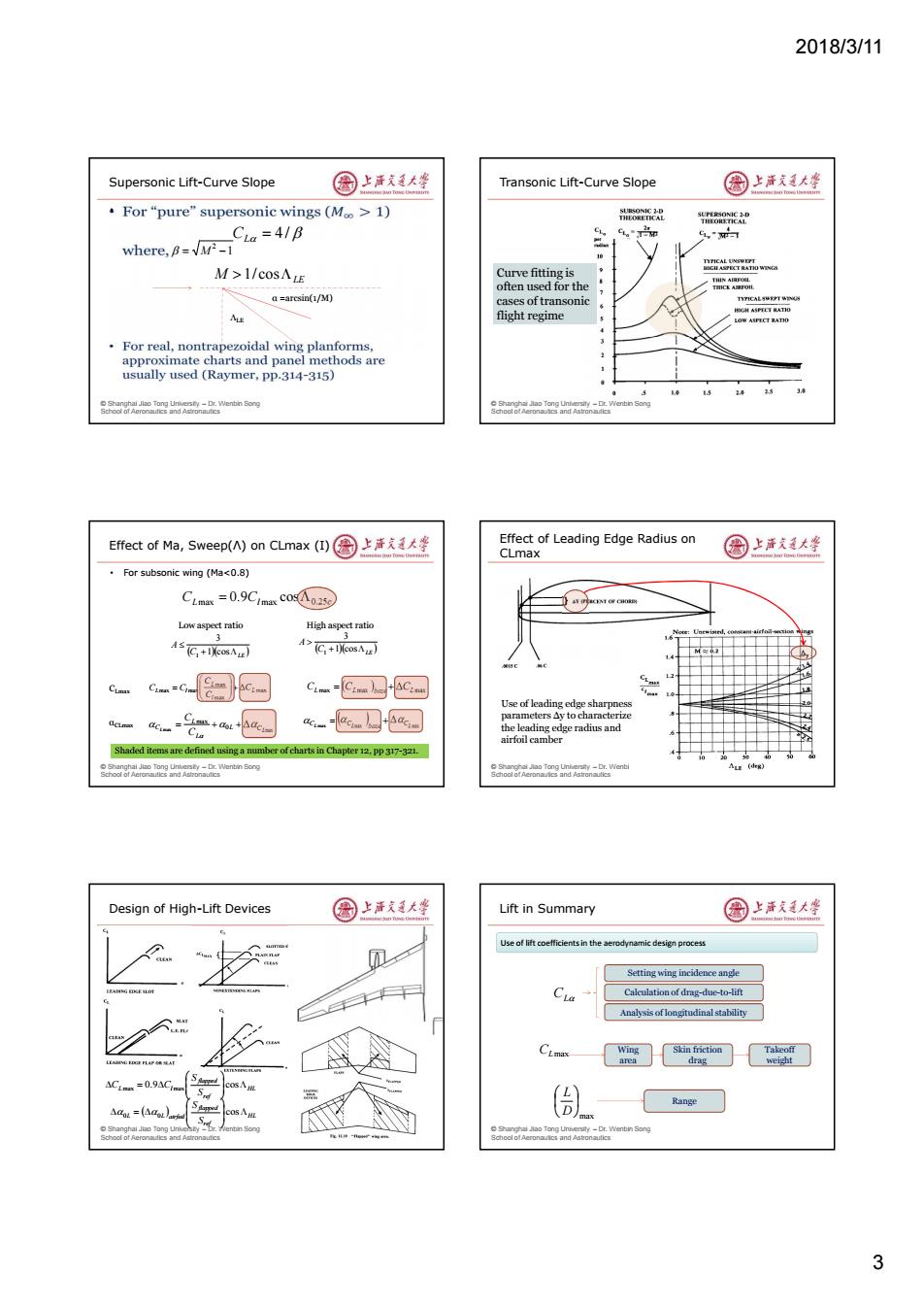

2018/3/11 Supersonic Lift-Curve Slope 国上唐美大坐 Transonic Lift-Curve Slope 国上清大学 ·For“pure”supersonic wings(Mo>l) 8a2提 THEDRO TICAL La=41B 5,"m- where,B=M-1 M>1/COsALE Curve fitting is SICI AL BCT RATIO WIMA often used for the a =aresin(1/M) cases oftransonic flight regime OW ASPECT RAT For real,nontrapezoidal wing planforms, approximate charts and panel methods are usually used (Raymer,pp.314-315) 15 5 Erfect of Ma,Sweep()on CLmax()圈上活支道大坐 Effect of Leading Edge Radius on CLmax 园上活道大整 For subsonic wing (Ma<0.8) CLmas=0.9C1mxco个025 Low aspect ratio High aspect ratio 3 4 C.+lcosA 16 45C.+IXcOsAu) -o C-CAC. Use of leading edge sharpness _C+a+小e parameters Ay to characterize eratsad Shaded items are defined using a number ofcharts in Chapter 12.pp317-321. Design of High-Lift Devices 国上洋大坐 Lift in Summary 园上海发大坐 Use of lift coefficients in the aerodynamic design process Setting wing incidence angle C Caleulation of drag-due-to-lift Analysis of longitudinal stability CLma Takeoff weight △CLm=0.9AC D Range Aau=(△au) slty-Dr.V(enbin Song 3

2018/3/11 3 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Supersonic Lift-Curve Slope • CL 4 / 1 2 M α =arcsin(1/M) ΛLE M LE 1/ cos © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Transonic Lift-Curve Slope Curve fitting is often used for the cases of transonic flight regime © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Effect of Ma, Sweep(Λ) on CLmax (I) • For subsonic wing (Ma<0.8) CLmax Cl max 0.25c 0.9 cos C LE A 1 cos 3 1 C LE A 1 cos 3 1 Low aspect ratio High aspect ratio CLmax αCLmax max max max max max L l L L l C C C C C max max 0 max L L CL L L C C C CLmax CLmax base CLmax CL max CL max base CLmax Shaded items are defined using a number of charts in Chapter 12, pp 317-321. © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Effect of Leading Edge Radius on CLmax Use of leading edge sharpness parameters Δy to characterize the leading edge radius and airfoil camber © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Design of High-Lift Devices HL ref flapped L l S S C C 0.9 cos max max HL ref flapped L L airfoil S S cos 0 0 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Lift in Summary CL CLmax max D L Wing area Skin friction drag Takeoff weight Range Setting wing incidence angle Calculation of drag-due-to-lift Analysis of longitudinal stability Use of lift coefficients in the aerodynamic design process

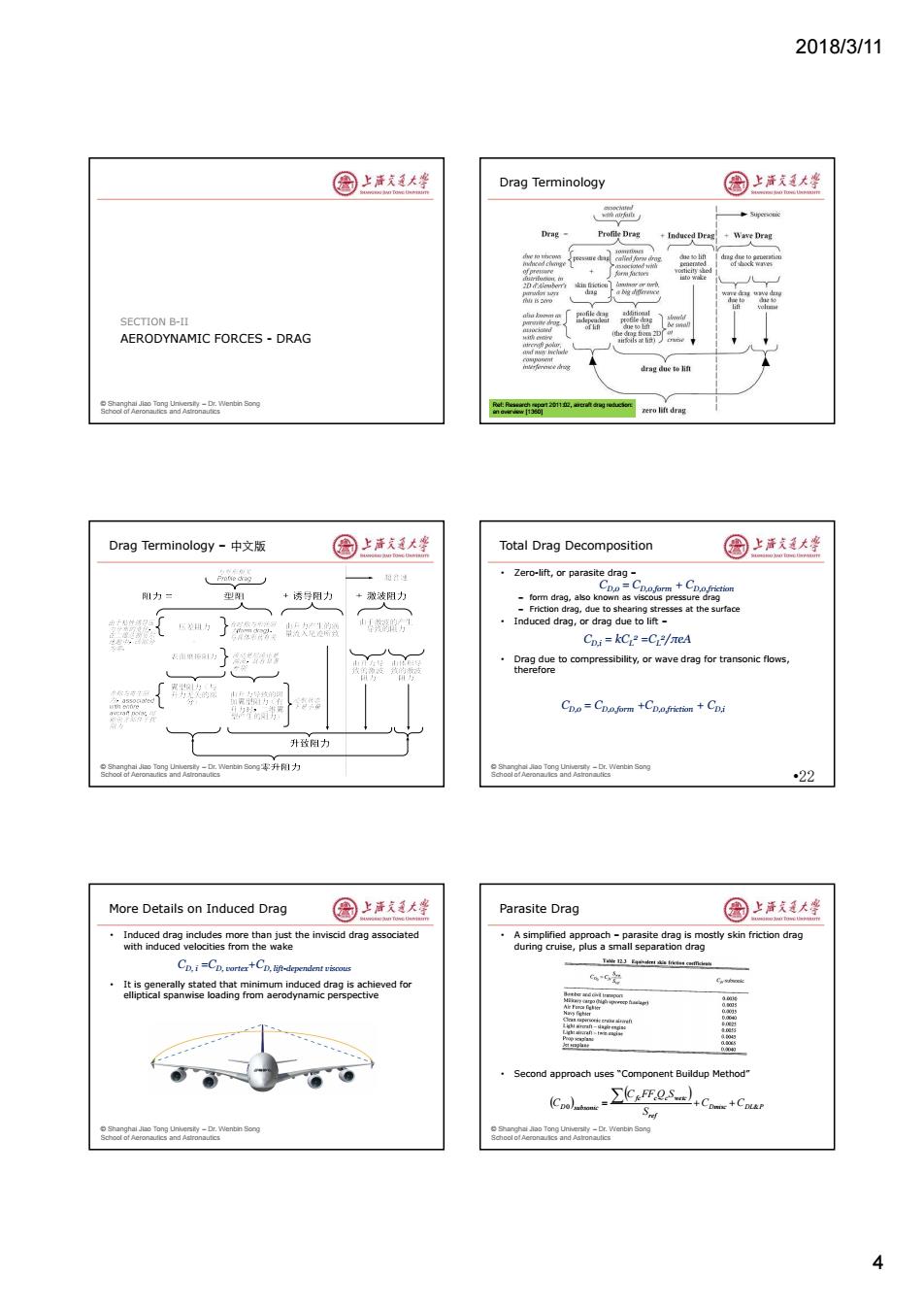

2018/3/11 圆上活大学 Drag Terminology 国上清大学 Drag- Profile Drag +Induced Drag!+Wave Drag 恤rg然am SECTION B-II AERODYNAMIC FORCES-DRAG oorornenin ong zero lift drag Drag Terminology-中文版 国上活大坐 Total Drag Decomposition 圆上洋廷大整 Fratve dag 日过 Zero-lift,or parasite drag- 即力二 型用 +诱导阻力 +激波阻力 农 1 Induced drag,or drag due to lift- Cni=kC2=CLπeA Drag due to compressibility,or wave drag for transonic flows, therefore Cpo=Cpoform +Cpofriction+Cpi 升致阳力 nbin Song零升阴力 oerandenn ong 22 More Details on Induced Drag 国上洋大坐 Parasite Drag 国上洋大学 with induced Cp.i-Cp.Cp. CoC Second approach uses"Component Buildup Method" CccCr Shanghal Jao Tong Universty-Dr.Wenbin Soog erslty-Dr.Wrenbin Song 4

2018/3/11 4 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics AERODYNAMIC FORCES - DRAG SECTION B-II © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Drag Terminology Ref: Research report 2011:02, aircraft drag reduction: an overview [1360] © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Drag Terminology – 中文版 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Total Drag Decomposition • Zero-lift, or parasite drag – – form drag, also known as viscous pressure drag – Friction drag, due to shearing stresses at the surface • Induced drag, or drag due to lift – • Drag due to compressibility, or wave drag for transonic flows, therefore •22 CD,0 = CD,0,form + CD,0,friction CD,i = kCL 2 =CL 2 /πeA CD,0 = CD,0,form +CD,0,friction + CD,i © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics More Details on Induced Drag • Induced drag includes more than just the inviscid drag associated with induced velocities from the wake • It is generally stated that minimum induced drag is achieved for elliptical spanwise loading from aerodynamic perspective CD, i =CD, vortex+CD, lift-dependent viscous © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Parasite Drag • A simplified approach – parasite drag is mostly skin friction drag during cruise, plus a small separation drag • Second approach uses “Component Buildup Method” Dmisc DL P ref fc c c wetc D subsonic C C S C FF Q S C 0 &

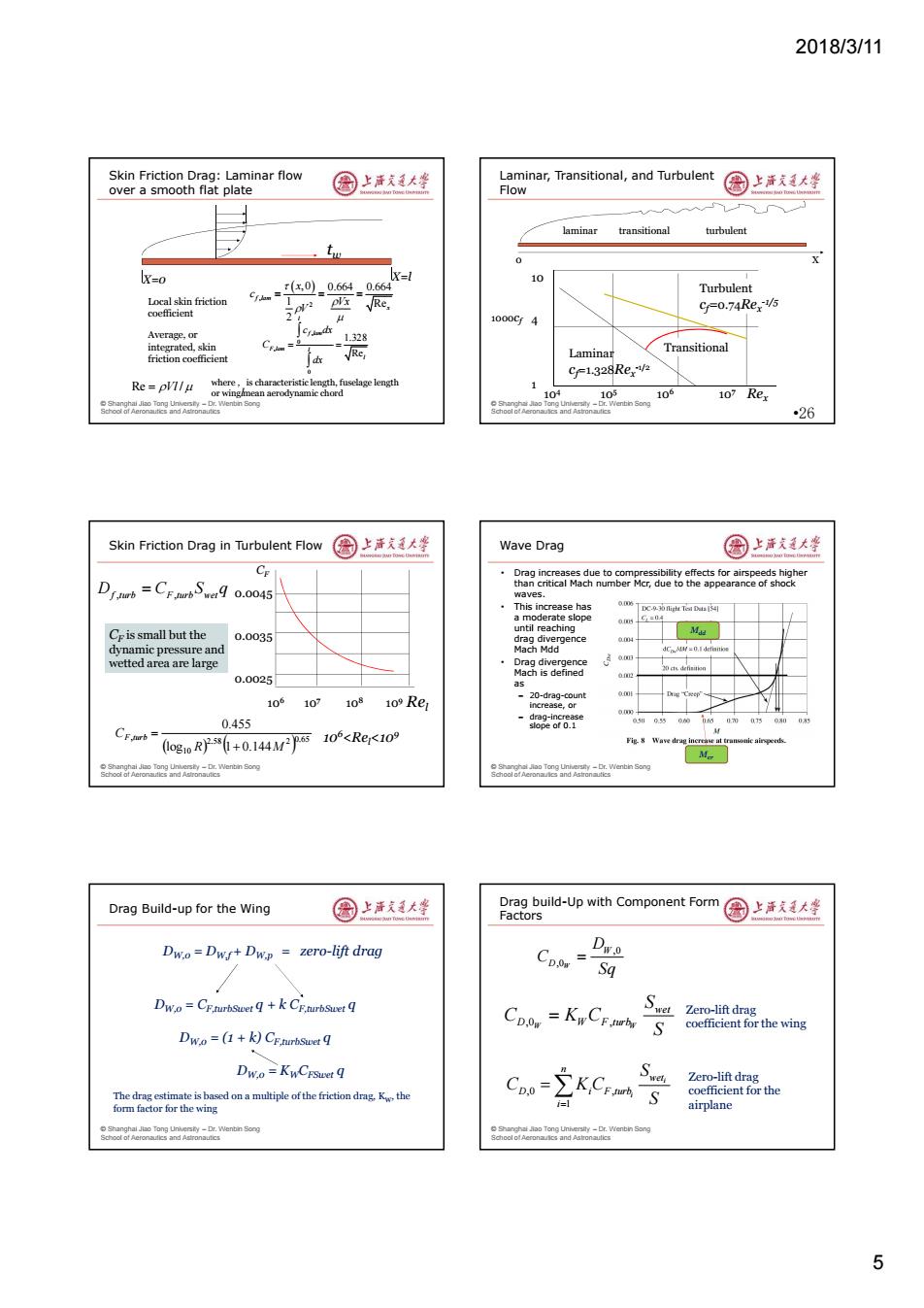

2018/3/11 Skin Friction Drag:Laminar flow Laminar,Transitional,and Turbulent over a smooth flat plate 图上清大华 Flow 圈上清文大华 laminar transitional turbulent X=0 X=1 9=0.064.06 10 Turbulent Local skin friction 1 Re, coefficient -0.74Rex6 1000C4 Average,or C= 1.328 Transitional friction coefficient Rer Laminar C=1.328Rex12 Re=pV1/u where,is characteristic length,fuselage length 1 or winglean aerodynamic chord 104 105 106 107 Rex ong 26 Skin Friction Drag in Turbulent Flow 国上活大蜂 Wave Drag 国上活支大峰 Drag increases due to compressibility effects for airspeeds higher DI=CFASq 0.0045 than critical Mach number Mcr,due to the appearance of shock waves. ·This increase has a moderate slope 05 until reachina Cris small but the 0.0035 drag divergence dynamic pressure and Mach Mdd wetted area are large ·Drag diverge Mach is defined 0.0025 02 as 70- 106107 nt ge or 0.455 CFhrb (l0gR)s1+0.144M2p65 106<Re<109 Fig.8 Wave drag inerease at transonie airxpeeds. M。 Drag Build-up for the Wing 国上清大学 Drag build-Up with Component Form Factors 园上清天大学 Dw.o=Dwr+Dw.p zero-lift drag CD.or= wg Sq Dwo=CEnurbswet q+k CEnurbswet q Cooe -KyCrah SeZer- coefficient for the wing Dwo=(1+k)CEnirbSwet q Dw.o=KwCrsuet q CD.o= KC S Zero-lift drag The drag estimate is based on a multiple of the friction drag.K,the coefficient for the form factor for the wing -1 airplane erslty-Dr.V(enbin Song 5

2018/3/11 5 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Skin Friction Drag: Laminar flow over a smooth flat plate tw , 2 , 0 0.664 0.664 1 Re 2 f lam x x c Vx V , 0 , 0 1.328 Re l f lam F lam l l c dx C dx Local skin friction coefficient Average, or integrated, skin friction coefficient X=0 X=l Re Vl / where , is characteristic length, fuselage length or wing mean aerodynamic chord l © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Laminar, Transitional, and Turbulent Flow •26 laminar transitional turbulent 104 105 106 107 Rex 10 4 1 1000cf Turbulent cf=0.74Rex -1/5 Laminar cf=1.328Rex -1/2 Transitional 0 X © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Skin Friction Drag in Turbulent Flow D C S q f turb F turb wet , , 106<Rel<109 CF is small but the dynamic pressure and wetted area are large 0.65 2.58 2 10 , log 1 0.144 0.455 R M CF turb 106 107 108 109 Rel 0.0045 0.0035 0.0025 CF © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Wave Drag • Drag increases due to compressibility effects for airspeeds higher than critical Mach number Mcr, due to the appearance of shock waves. • This increase has a moderate slope until reaching drag divergence Mach Mdd • Drag divergence Mach is defined as – 20-drag-count increase, or – drag-increase slope of 0.1 Mcr Mdd © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Drag Build-up for the Wing DW,0 = DW,f + DW,p = zero-lift drag DW,0 = CF,turbSwet q + k CF,turbSwet q DW,0 = (1 + k) CF,turbSwet q DW,0 = KWCFSwet q The drag estimate is based on a multiple of the friction drag, KW, the form factor for the wing © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Drag build-Up with Component Form Factors ,0 ,0W W D D C Sq ,0 , W W wet D W F turb S C K C S ,0 , 1 i i n wet D i F turb i S C K C S Zero-lift drag coefficient for the wing Zero-lift drag coefficient for the airplane

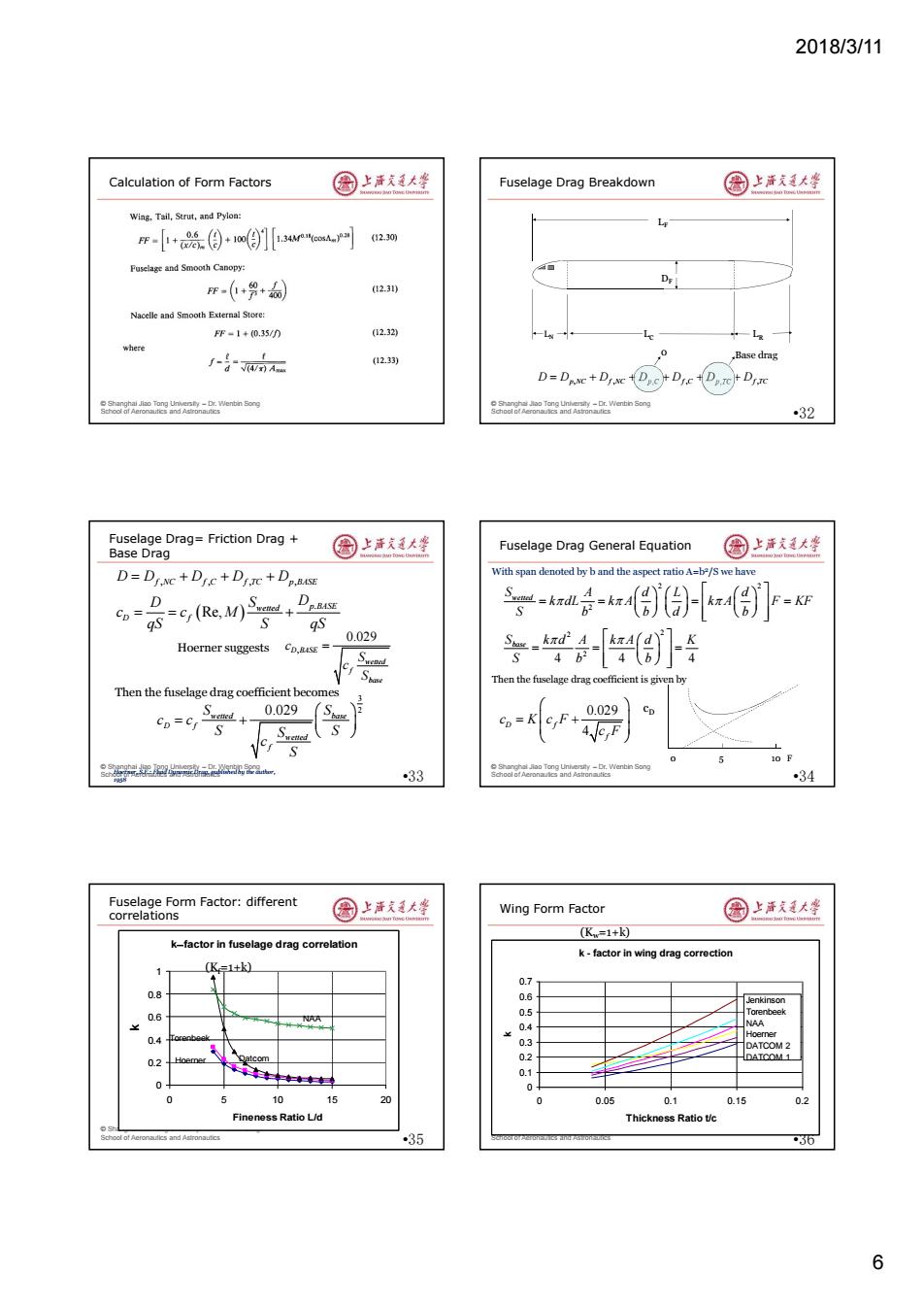

2018/3/11 Calculation of Form Factors 园上清大华 Fuselage Drag Breakdown 国上清大学 Wing,Tail,Strut,and Pylon F-+0(自+m目】儿网 2.30 Fuselage and Smooth Canopy: m-(+9+ 123) Nacelle and Smooth External Store: FF-1+(0.35/n 02.32 where 了-导mA (12.33) 0 .Base drag D=DANC+DINC DC DIcD.rC DiTe oorornenin ong oorn enin Song 32 Fuselage Drag=Friction Drag Base Drag 圆上清大坐 Fuselage Drag General Equation 圈上活大整 D=DINC DIc+Di+Dp.BuSE With span denoted by b and the aspect ratio A=b2/S we have D Dp.BASE 学-业会a份)xd8)]F- 0.029 Hoerner suggests Co,auSE= Then the fuselage drag coefficient is given by Then the fuselage drag coefficient becomes 0.029 s Co-K cyF+ 0.029 10F s是20器,aw 33 34 Fuselage Form Factor:different correlations 图上洋大峰 Wing Form Factor 圆上清大学 (Kw=1+) k-factor in fuselage drag correlation k-factor in wing drag correction K=1+k) 01 0.8 nkinson 0.6 0.5 0.4 8 0.2 Qatcom 0.1 0 ★★三 10 15 20 0 0.05 0.1 0.15 0.2 Fineness Ratio Ud Thickness Ratio tc 35 36 6

2018/3/11 6 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Calculation of Form Factors © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Fuselage Drag Breakdown •32 LN LF LC LR DF D D D D D D D p NC f NC p C f C p TC f TC , , , , , , 0 Base drag © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Fuselage Drag= Friction Drag + Base Drag •33 , , , , . Re, f NC f C f TC p BASE wetted p BASE D f D D D D D D S D c c M qS S qS , 0.029 D BASE wetted f base c S c S Hoerner suggests 3 0.029 2 wetted base D f wetted f S S c c S S S c S Then the fuselage drag coefficient becomes Hoerner, S.F.: Fluid Dynamic Drag, published by the author, 1958 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Fuselage Drag General Equation •34 2 2 2 2 2 2 4 4 4 wetted base S A d L d k dL k A k A F KF S b b d b S k d A k A d K S b b With span denoted by b and the aspect ratio A=b2 /S we have 0.029 4 D f f c K c F c F Then the fuselage drag coefficient is given by 0 5 10 F cD © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Fuselage Form Factor: different correlations •35 kfactor in fuselage drag correlation 0 0.2 0.4 0.6 0.8 1 0 5 10 15 20 Fineness Ratio L/d k NAA Datcom Torenbeek Hoerner(Kf=1+k) © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Wing Form Factor •36 k - factor in wing drag correction 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0 0.05 0.1 0.15 0.2 Thickness Ratio t/c k Jenkinson Torenbeek NAA Hoerner DATCOM 2 DATCOM 1 (Kw=1+k)

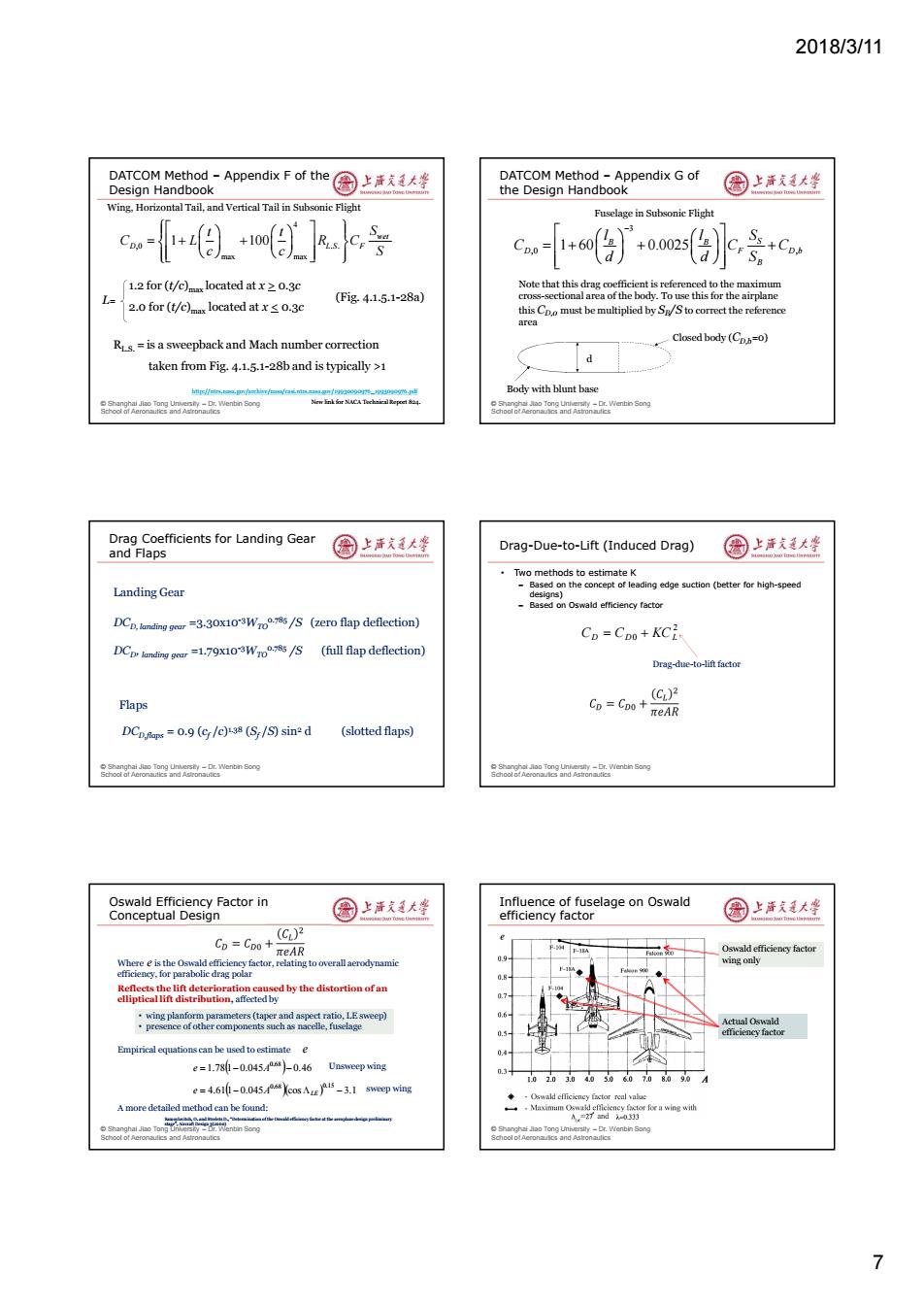

2018/3/11 DATCOM Method-AppendixFof the国上活支美大聋 DATCOM Method -Appendix G of Design Handbook the Design Handbook 国上清大学 Wing.Horizontal Tail,and Vertical Tail in Subsonic Flight Fuselage in Subsonic Flight 1.2 for(t/e)located atx0.3c Note that this drag coefficient is referenced to the maximum (Fig4.1.5.1-28a) cross-sectional area of the body.To use this for the airplane 2.0 for (t/c)located at x1 Body with blunt base oandn ong Drag Coefficients for Landing Gear and Flaps 圆上清道大坐 Drag-Due-to-Lift (Induced Drag) 园上活道大整 Two methods to estimate K Landing Gear -Based on the concept of leading edge suction(better for high-speed designs) -Based on Oswald efficiency factor DCp.ding=3-30x103Wro/(zero flap deflection) Cp=Cpo+KCi DCp.lndin r=179x103Wo/S (full flap deflection) Drag-due-to-lift factor Flaps Cp=CDo+ C)2 eAR DCpnaps=0.9(c/c)(S/S)sind (slotted flaps) nwentin ong oerandenn ong Oswald Efficiency Factor in Influence of fuselage on Oswald Conceptual Design 国上清大学 efficiency factor 园上海发大坐 Cp=Cpo+ (C)2 Oswald efficiency factor wing onlv 0.8 Reflects the lift deterioration eaused by the distortion of an elliptical lift distribution,affected by wing planform parameters (taper and aspect ratio,LE sweep) 06 .presence of other components such as nacelle,fuselage Actual Oswald 0.5 efficiency factor Empirical equations can be used to estimate e 0.4- e=1.78l-0.0454-0.46 Unsweep wing 1.3 0203.04030607.08090A e=4.611-0.045Ycos AL)15-3.1 sweep wing Oswald efficieney factor real value A more detailed method can be found: 。一,Maximum Oswald eficiency ctorfowing with A=27d00 slty-Dr.W(enbin Song 7

2018/3/11 7 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics DATCOM Method – Appendix F of the Design Handbook Wing, Horizontal Tail, and Vertical Tail in Subsonic Flight 4 ,0 . . max max 1 100 wet D L S F t t S C L R C c c S L= 1.2 for (t/c)max located at x > 0.3c 2.0 for (t/c)max located at x 1 (Fig. 4.1.5.1-28a) http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19930090976_1993090976.pdf New link for NACA Technical Report 824. © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics DATCOM Method – Appendix G of the Design Handbook Fuselage in Subsonic Flight 3 ,0 , 1 60 0.0025 B B S D F D b B l l S C C C d d S Note that this drag coefficient is referenced to the maximum cross-sectional area of the body. To use this for the airplane this CD,0 must be multiplied by SB /S to correct the reference area Body with blunt base Closed body (CD,b=0) d © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Drag Coefficients for Landing Gear and Flaps DCD, landing gear =3.30x10-3WTO 0.785 /S (zero flap deflection) DCD, landing gear =1.79x10-3WTO 0.785 /S (full flap deflection) DCD,flaps = 0.9 (cf /c)1.38 (Sf /S) sin2 d (slotted flaps) Landing Gear Flaps © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Drag-Due-to-Lift (Induced Drag) • Two methods to estimate K – Based on the concept of leading edge suction (better for high-speed designs) – Based on Oswald efficiency factor 2 CD CD0 KCL Drag-due-to-lift factor © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Oswald Efficiency Factor in Conceptual Design Samoylovitch, O. and Strelets D., “Determination of the Oswald efficiency factor at the aeroplane design preliminary stage”, Aircraft Design 3(2000) Where is the Oswald efficiency factor, relating to overall aerodynamic efficiency, for parabolic drag polar Reflects the lift deterioration caused by the distortion of an elliptical lift distribution, affected by • wing planform parameters (taper and aspect ratio, LE sweep) • presence of other components such as nacelle, fuselage e Empirical equations can be used to estimate e 1.781 0.045 0.46 0.68 e A 4.611 0.045 cos 3.1 0.68 0.15 e A LE Unsweep wing sweep wing A more detailed method can be found: © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Influence of fuselage on Oswald efficiency factor Oswald efficiency factor wing only Actual Oswald efficiency factor

2018/3/11 Oswald Factors of Some Aeroplanes 圈上声哀道大学 Trim Drag 国上清大学 Horizontal tail force is typically required to balance(trim)the aircraft A For conve downlo -t0- 41 Trim drag can be reduced using techniques such as relaxed static stability (RSS) △L ornenin Song Summary 国上道大峰 国上清支大峰 Aerodynamic efficiency 。 Aerodynamic forces in preliminary design icients, CLa High-lift devices (L D) -Estimation of drag coefficients Cp=CpoformCpafriction CDi=kC2=CL2/teA SECTION C CFD-BASED AERODYNAMIC SHAPE Commonly used methods OPTIMISATION -DATCOM method -ESDU -Some textbook orandenn ong Table of Contents 图上洋大峰 Design Process And CFD 园上海发大坐 Development of computational fluid dynamics(CFD) Use of computational tools in design CFD-based aerodynamic design -Objectives and constraints 品 design Shape parameterization methods Figure 2 The Agroeyame Desgn Process 8

2018/3/11 8 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Oswald Factors of Some Aeroplanes © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Trim Drag • Horizontal tail force is typically required to balance (trim) the aircraft • For conventional configurations, tails often operate in producing download force, leads to higher required lift from wing, therefore higher drag-due-to-lift • Trim drag can be reduced using techniques such as relaxed static stability (RSS) W L ΔL ΔL © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Summary • Aerodynamic efficiency • Aerodynamic forces in preliminary design – Estimation of lift coefficients, • Clean configuration • High-lift devices – Estimation of drag coefficients • Commonly used methods – DATCOM method – ESDU – Some textbook C L C L max max D L CD,0 = CD,0,form + CD,0,friction CD,i = kCL 2 =CL 2 /π𝑒𝐴 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics CFD-BASED AERODYNAMIC SHAPE OPTIMISATION SECTION C © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Table of Contents • Development of computational fluid dynamics (CFD) • Use of computational tools in design • CFD-based aerodynamic design – Objectives and constraints – Inverse design – Optimization methods – Shape parameterization methods © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Design Process And CFD Aerodynamic Shape Optimization: Exploring the Limits of Design, Jameson, et al., KSAS2003

2018/3/11 Typical Features of Aircraft Aerodynamic Design 圆上活大学 Use of CFD at Different Design Stages 国上清大学 Plays leading role in preliminary design ·Conceptual design Extemal shape determined during preliminary design ction of configurations 2-4 iterations with each taking 4-6 months ANriolselection -Starts with the definition of clean wing Wing planform wing-body or wing-body-nacelle-pylon follows Fuselage Tail sizing Key points in flight envelope ·Project design -cruise,climb,long-range cruise,cruise at high/low lift,etc. Buffett conditions with 1.3g -Both airfoil sections and wing planform parameters considered Detail design Fine-tuning of detail shapes -Minor modifications rrcn ein o oorn enin Song Role of Aerodynamic Design 圈上活文大些 Applications of CFD in Civil Aircraft Design 国上活道大坐 Aerodynamic Design Wind-Tunnel Deelgn Raynolds-Number Wind Tunnel Testing Stability and Wingand Tail Control Design Aeroelastic and Loads,Stresses fatigue and Deflections Structural Design Ref:432. Timeline of CFD methods and its applications 国圆上清发大坐 Use of CFD in aerodynamic design nA380y大¥ w品常三 15 Po E a380 Figure 3.Effect of CFDon Configunation Lines Wind Tunnel Development Testing slty-Dr.W(enbin Song Source:x265c 9

2018/3/11 9 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Typical Features of Aircraft Aerodynamic Design • Plays leading role in preliminary design • External shape determined during preliminary design • 2-4 iterations with each taking 4-6 months – Starts with the definition of clean wing – wing-body or wing-body-nacelle-pylon follows – Whole aircraft simulation • Key points in flight envelope – cruise, climb, long-range cruise, cruise at high/low lift, etc. – Buffett conditions with 1.3g – Both airfoil sections and wing planform parameters considered © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Use of CFD at Different Design Stages • Conceptual design – Selection of configurations – Airfoil selection – Wing planform – Fuselage – Tail sizing • Project design – Shape design of components – Interference simulation • Detail design – Fine-tuning of detail shapes – Minor modifications © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Role of Aerodynamic Design Wind Tunnel Testing Computational Fluid Dynamics Stability and Control Wing and Tail Design Aeroelastic and fatigue Loads, Stresses, and Deflections Aerodynamic Design Structural Design © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Applications of CFD in Civil Aircraft Design Ref: 432. © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Timeline of CFD methods and its applications © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Use of CFD in aerodynamic design on A380 54 Source: x265c

2018/3/11 Where are we going 园上声哀通大学 CFD Simulation Models 国上清大学 CED has hecome a Lifting-line theory major de Panel codeAlsoknown as boundaryelement methods,fast,2D/3D Full Potential code Rotational terms dropped atom Navier-Stokes Equations Euler codes Viscous terms dropped Various turbulence models.RANS MDA and MDO in Cannot be analytically 品e solved so far Large Eddy Used on simplified geometries mprovements Supercomputing Direct Numerical Siulation (DNS) Largely research topic CFD simulation is usually a tradeoff among model fidelity,numerical accuracy and setup/computing time.Book to read "Computational Fluid Dynamics"by Anderson Aerodynamic Design Methods 圆上清文大些 Inverse design methods 圆上洋廷大蜂 Inverse design In inverse design methods,many designers prescribe the airfoil :eenet -Different flow models can be used f and define the o 0BI-8cnn-4p了 A baseline airfoil is selected as the starting point-some expertise is necessary to choose a good starting point -Two categor uasi-ewton,etc An iteration process is required to achieve convergence ary Methods: set as objectives and corstraints oernan Wen ong CFD-based Shape Optimization 国上清大学 How aircraft geometry was modelled 园上洋文大学 Input parameters(length,width,etc) Overall procedure used in CFD-based CAD Geometry aerodynamic optimization Mesh Generation Updated parameters (length,width,ete) Flow Solvers rslty-Dr.V(enbin Song 10

2018/3/11 10 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Where are we going 55 • CFD has become a major design tool, shape optimization is becoming more affordable • CFD needs to be developed in collaboration between Universities and Industry into a system of tools of various fidelity • MDA and MDO in industry settings will be one the key enablers for further improvements • Supercomputing continues to be an enabling factor © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics CFD Simulation Models Navier-Stokes Equations Cannot be analytically solved so far Lifting-line theory Panel code Euler codes Various N- S models Direct Numerical Simulation (DNS) Large Eddy Simulation Viscous terms dropped Various turbulence models, RANS Used on simplified geometries Also known as boundary element methods, fast, 2D/3D Largely research topic CFD simulation is usually a trade off among model fidelity, numerical accuracy and setup/computing time. Book to read “Computational Fluid Dynamics” by Anderson Full Potential code Rotational terms dropped © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Aerodynamic Design Methods • Inverse design – Different flow models can be used • Incompressible inviscid flow • Transonic potential flow • Euler and Navier-Stokes Model – Features: • Matching prescribed pressure distribution given by experienced engineers • Depends on the pressure distribution • More efficient compared to optimization methods • Optimization design – Two categories of methods • Gradient based approach: quasi-newton, etc – Control theory approach (Jameson) – Gradient computed using finite difference • Evolutionary Methods: genetic algorithms, etc – Features • Aerodynamic performances set as objectives and constraints • Optimized by shape modification based on different shape representations 57 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Inverse design methods • In inverse design methods, many designers prescribe the airfoil pressure distribution cp on the airfoil and define the objective function to be minimized as • A baseline airfoil is selected as the starting point – some expertise is necessary to choose a good starting point • An iteration process is required to achieve convergence OBJ (cpdesigni i1 N cpactuali ) 2 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics CFD-based Shape Optimization CAD Geometry Parameterization Mesh Generation (Discretization) Flow Solvers Input parameters (length, width, etc) Objective function and Constraints (lift, drag) Updated parameters (length, width, etc) Overall procedure used in CFD-based aerodynamic optimization Optimizers © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics How aircraft geometry was modelled Source: D.G. Clark and A. Gibson, Concord, Phoebus Publishing Company, 1976/77