2018/5/16 国上活大坐 Overview of Lectures 国上清大学 0.Overview 14/15 Performance(a,b) 16.Aircraft certification 2.Overall configuration 17.Aviation economics weight estimation 18.System integration and eigh estimation configuration management Aircraft Design Fuselage design 19.Multidisciplinary design 6/7/8 Aerodynamic design(a,b,c) ootimization (飞行器设计) .hat and ing 20.Military aircraft design-overview 21.Environmental issues 10.Landing gear and Aircraft systems 22.Design skills 11.Power plant Wenbin Song 12.Stability and control School of Aeronautics and Astronautics 13.Loads,materials and structures Shangy oorornenin ong Content 国上活大峰 国上清道大坐 Aircraft Configuration Management (CM) -Configuration definition (Definition Dossier) -CM plan,policies,and procedures Audits and Status Report Internal functions and External Suppliers System Integration-Concurrent Engineering Distributed engineering and manufacturing Digital Mock-Up -Virtual Reality (VR)and human simulations CONFIGURATION MANAGEMENT oerandenn ong What is Configuration Management 园上洋文通大学 Aircraft Life-Cycle Management 国上洋大学 。 Configuration management(构型管型)is the discipline that proper identification and versioning of the Objectives:Reduce operational cost and increase operational readiness of aircraft,while at the same time to ensure safety of passengers,staff and cargo urrent status of physical and functional component ·Ampea8nagsaemahetRegi6neaiaeeanmg9and /substructure,and eq Configura ation mana re is the means through which integrit tin ability are recorde Key Capabilities Configuration Management Configuration management efforts result in complete audit Component Life Accounting traceability of decisions and design modifications Operational Status Management erslty-Dr.V(enbin Song 1

2018/5/16 1 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Wenbin Song School of Aeronautics and Astronautics Shanghai Jiao Tong University swb@sjtu.edu.cn Aircraft Design (飞行器设计) © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Overview of Lectures 0. Overview 1. Introduction 2. Overall configuration 3. Preliminary weight estimation 4. Refined weight estimation 5. Fuselage design 6/7/8 Aerodynamic design(a, b, c) 9. Thrust/Weight ratio and wing loading 10.Landing gear and Aircraft systems 11.Power plant 12.Stability and control 13.Loads, materials and structures 14/15 Performance(a, b) 16.Aircraft certification 17.Aviation economics 18.System integration and configuration management 19.Multidisciplinary design optimization 20.Military aircraft design – overview 21.Environmental issues 22.Design skills © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Content • Aircraft Configuration Management (CM) – Configuration definition (Definition Dossier) – CM plan, policies, and procedures – Audits and Status Report – Internal functions and External Suppliers • System Integration – Concurrent Engineering – Distributed engineering and manufacturing – Digital Mock-Up – Virtual Reality (VR) and human simulations 3 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics CONFIGURATION MANAGEMENT 4 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics What is Configuration Management • Configuration management (构型管理) is the discipline that ensures the proper identification and versioning of the configuration – It controls current status of physical and functional component – It controls change, and records the change implementation status of the physical and functional characteristics of the structure, system/substructure, and equipment • Configuration management therefore is the means through which integrity and continuity of the design, systems engineering and supportability are recorded, communicated, and controlled 5 Configuration management efforts result in complete audit traceability of decisions and design modifications © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Aircraft Life-Cycle Management • Objectives: Reduce operational cost and increase operational readiness of aircraft, while at the same time to ensure safety of passengers, staff and cargo • Although targeted mainly at operational stage, the planning and implementation of such system is done at the design stage 6 Key Capabilities • Configuration Management • Component Life Accounting • Operational Status Management

2018/5/16 Concepts and Definitions 园上声克大婆 Concepts and Definitions (cont.) 国上清大学 ·Configuration(构型) ·Baseline(基线) s a complete definition with regard to a product, -It is formulated in design,and used in manufacture,MRO,after-sale, and updated along its complete life cycle ·Configuration Item(为型项) Configuration Management(构型管理) Develop management plans,policies and procedures yin the doumntaion manaemeprce Preparation of audit plan Example of What is a configuration guB.eeegntolhichpatisvaianvhiehposicnonanaircratsnuetureor Tocls,software. It is used to co ·Change(更改) Any design shall be considered asa change CM is underpinned by technical records It requires a robust,efficient process supported by a IT system process. CM Functions and Principles 圈上清文大坐 Aircraft Configuration 国上清我道大孝 Five functions can be identified within the CM procedures Aireraft Configuration (MSNxxx) Each aircraft is 5Verification and Audit CA.. Each function is Functional Functional also uniquely dentified (FI) Technical Technical Solutions (TS) Solutions (TS) Solutions (TS) 院dindieren 1Planning and Management Definition Summary Table including configuration hange table Definition of Configuration Structure 图上洋天通大学 CM in Design 图上活大坐 What level of details are required in aircraft configuration for A configuration is set of drawings,specifications,and data. manufacturers -Drawing set -Engineering Reference Data:is defined in design and contains all the Schedule automatic part list) details relating to aircraft components Engineering Change Note(ECN) eutabse on Flowchart for defining the configuration document Airlines may need a different configuration definition based on the type of contract and level of maintenance work carried out 一时作与生用子生r作化一 interally 世门 珠重万 -More detailed configuration information is required if more maintenance work is done intemally 一4支挎图问 -Maintenance work maybe outsourced to MROs 系视参零文件 阁1定义文件定制过程 erslty-Dr.V(enbin Song 2

2018/5/16 2 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Concepts and Definitions • Configuration (构型) – Configuration provides a complete definition with regard to a product, for its entire life cycle – It is formulated in design, and used in manufacture, MRO, after-sale, and updated along its complete life cycle • Configuration Management (构型管理) – Establish the aircraft configuration – Develop management plans, policies and procedures – Preparation of audit plan 7 What is a configuration It is used to control ‘which part is valid in which position on an aircraft structure or sub-assembly’ CM is underpinned by technical records It requires a robust, efficient process supported by a IT system © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Concepts and Definitions (cont.) • Baseline (基线) – An agreed definition of the equipment at a point of time, including all approved documents that represent its definition, which serve as a reference for further activities • Configuration Item (构型项) – An aggregation of hardware, software, processed materials, services, documents that is designated for Configuration Management and treated as a single entity in the documentation management process. Example of CI include • Equipment, sub assembly, electronic board, software component… • Specification, plans… • Tools, software utilities… • Change (更改) – Any alteration to an equipment design shall be considered as a change. – The word "change" is the generic term for equipment modification, amendment or "other change" to the design or to the production process. 8 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics CM Functions and Principles • Five functions can be identified within the CM procedures 9 ⑤Verification and Audit ①Planning and Management ②Identification ③Change Management ④Status Accounting © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Aircraft Configuration • Each aircraft is uniquely identified using MSN001, 002… • Aircraft is a set of unique CAs • Each function is also uniquely identified (FI) • Each FI can have several different TSs • Technical solutions can be used in different FIs 10 Aircraft Configuration (MSNxxx) Constituent Assembly/CA Constituent Assembly/CA Constituent Assembly/CA CA… Functional Identifiers/FI Functional Identifiers/FI Functional Identifiers/FI Functional Identifiers/FI Technical Solutions (TS) Technical Solutions (TS) Technical Solutions (TS) Definition Summary Table including configuration change table © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Definition of Configuration Structure • What level of details are required in aircraft configuration for manufacturers – Engineering Reference Data: is defined in design and contains all the details relating to aircraft components – Can be based on customized structures, but is usually based on standard structures (ATA chapter) • Airlines may need a different configuration definition based on the type of contract and level of maintenance work carried out internally – More detailed configuration information is required if more maintenance work is done internally – Maintenance work maybe outsourced to MROs 11 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics CM in Design • A configuration is set of drawings, specifications, and data. – Drawing set – Schedule ( automatic part list) – Engineering Change Note (ECN) • Flowchart for defining the configuration document 12

2018/5/16 Change Management 园上声大学 Configuration Modification Procedure 周上洋文大学 Change management process before and after the initial delivery 。Change Proposals rers including third 次型球他变议料E aaheal -From customers-version modificati Investigation 两数中及 Feasibility -Deadline constraint 和格有□ -Airworthiness regulations,etc PRS-CH -Cost implications Technical Retumn Sheet 空多经可清汉象有合+用 一地红士双特0b ·Evaluation Implementation after approval CM for Manufacturing 圈上活大坐 CM for MRO 国上洋道大警 Digital factory (e-manufacturing) The aircraft configuration master layout,defined as a tree -Manufacturing data maintained in a centralized e-Manufacturing Server structure in AURA*,typical of most CM software systems database -Available to all authorized engineers regardless of their physical ocation Spirent Systems on wenin ong Deliverables for a Configuration Management 国圆上清发大坐 Configuration Management Plan 园上海发大坐 The following items should be included: Configuration Management Procedures Configuration Management Plan(CMP) -Problem Reporting -Configuration Management Assurance Interface with the Purchaser Configuration Management Configuration Index Document(CID) Interface with Sub-Contractors Configuration Management -CMP Template Equipment Definition Evolution Sheet(EDES) Vendor Service Bulletin 3

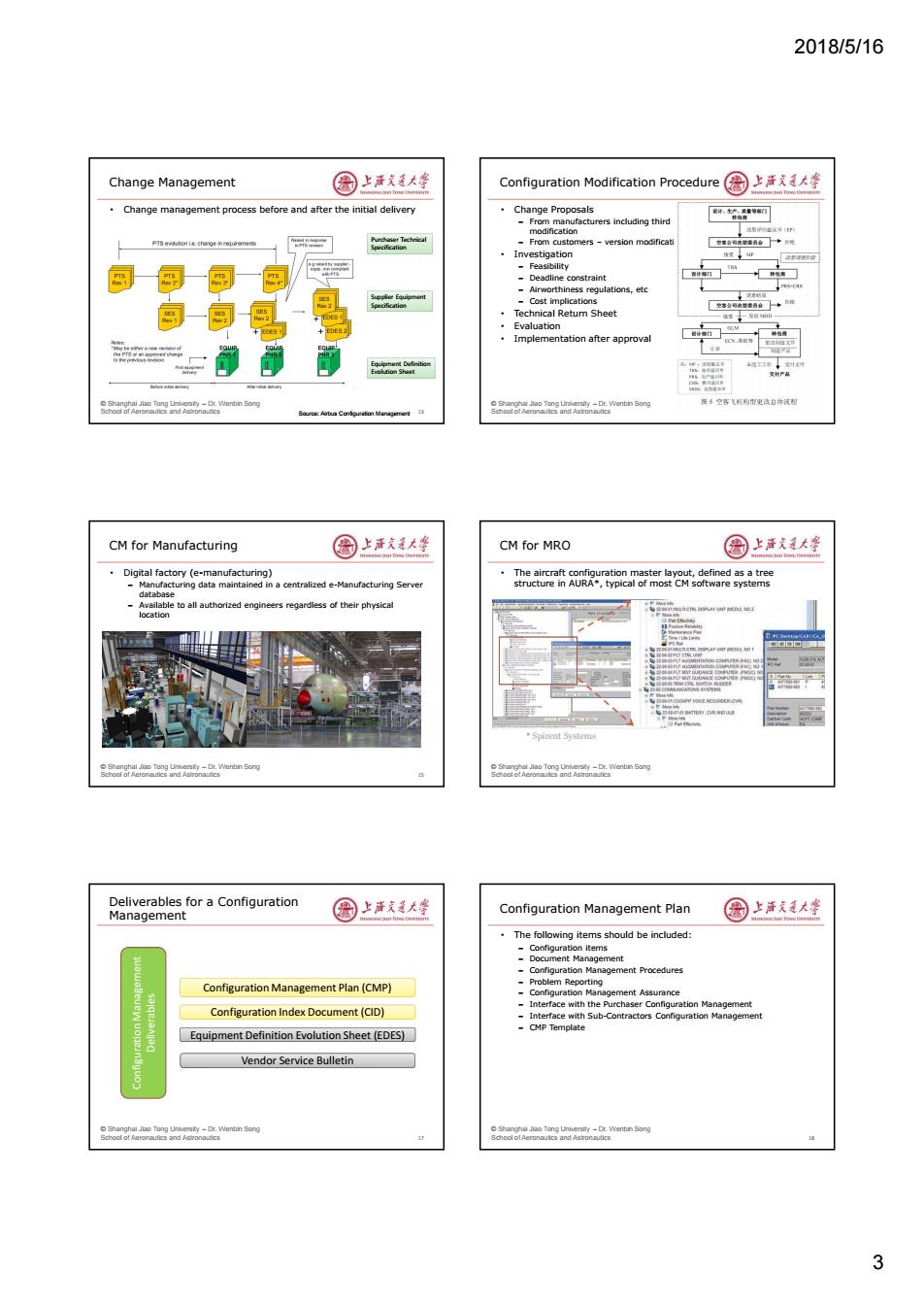

2018/5/16 3 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Change Management • Change management process before and after the initial delivery Source: Airbus Configuration Management 13 Purchaser Technical Specification Supplier Equipment Specification Equipment Definition Evolution Sheet © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Configuration Modification Procedure • Change Proposals – From manufacturers including third party suppliers – standard modification – From customers – version modification • Investigation – Feasibility – Deadline constraint – Airworthiness regulations, etc – Cost implications • Technical Return Sheet • Evaluation • Implementation after approval 14 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics CM for Manufacturing • Digital factory (e-manufacturing) – Manufacturing data maintained in a centralized e-Manufacturing Server database – Available to all authorized engineers regardless of their physical location 15 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics CM for MRO • The aircraft configuration master layout, defined as a tree structure in AURA*, typical of most CM software systems * Spirent Systems © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Deliverables for a Configuration Management 17 Configuration Management Plan (CMP) Configuration Index Document (CID) Equipment Definition Evolution Sheet (EDES) Vendor Service Bulletin Configuration Management Deliverables © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Configuration Management Plan • The following items should be included: – Configuration items – Document Management – Configuration Management Procedures – Problem Reporting – Configuration Management Assurance – Interface with the Purchaser Configuration Management – Interface with Sub-Contractors Configuration Management – CMP Template 18

2018/5/16 CM today status 园上声克大学 Looking ahead for CM 国上清大学 CM is closely linked with development of IT infrastructure CM in Product Life-Cycle Management(PLM)tools Technology-intensive Become more data tric and work-centri Implementation of CM is also a culture issue intelligence mainly for AFROSPACE INDUSTRY ENVIRONMENT rnennon oo andn ng 圆上清文大些 System Integration mission 园上活道大整 Scope:integrate data and information,satisfying the following requirements -Performance Reliability and maintenance -Airworthiness requirements Low cost and on time process,metl SYSTEM ENGINEERING INTEGRATION nwentin ong oernan Wen ong Example AIRBUS production distribution 国上清大坐 System Integration I what(1) 圆上清文大等 AIKBUS-Prance Distributed engineering and manufacture Design flowchart RBUS-UX A340-300 shown Production sharing by the Centres of Competence erslty-Dr.V(enbin Song 4

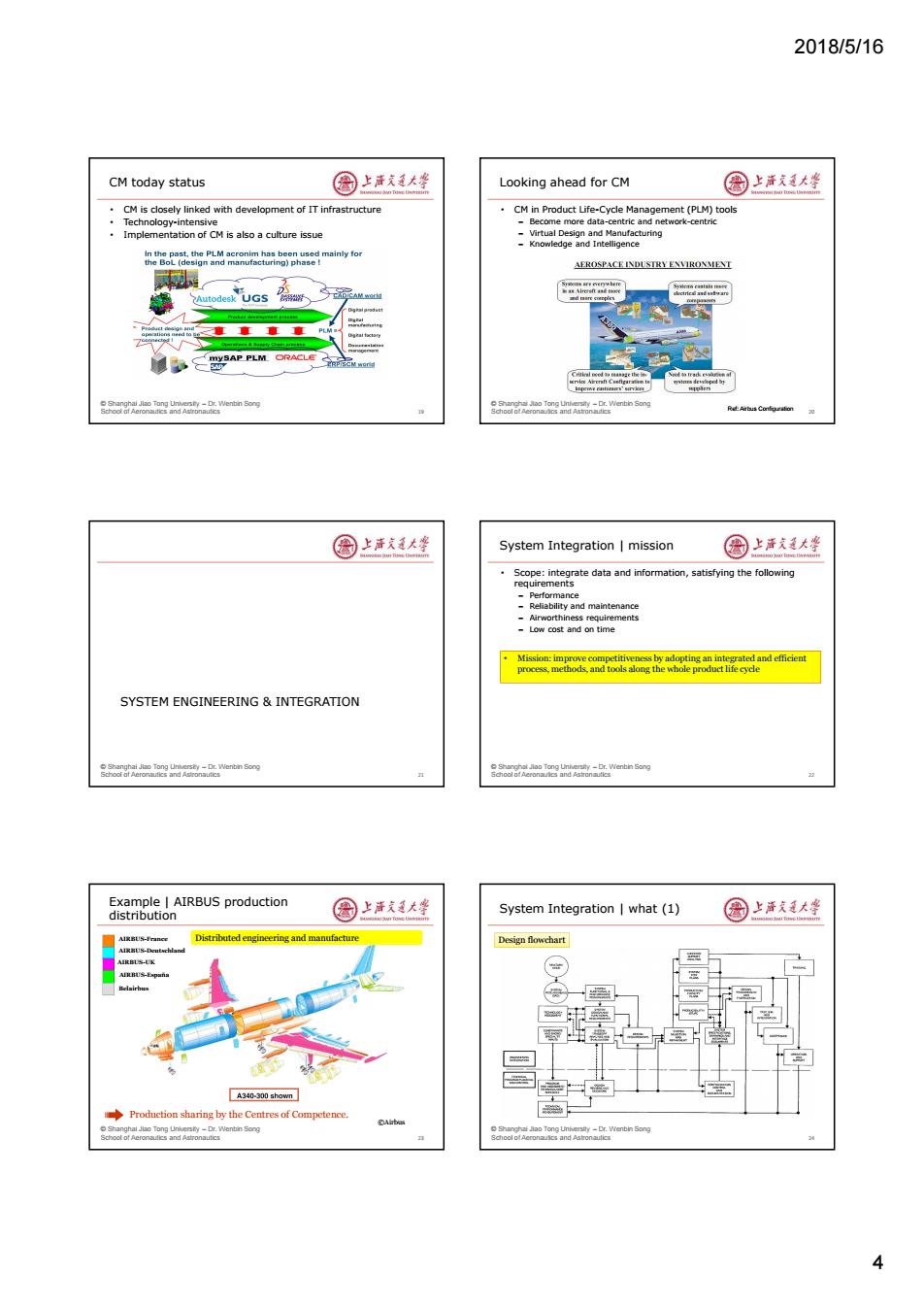

2018/5/16 4 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics CM today status • CM is closely linked with development of IT infrastructure • Technology-intensive • Implementation of CM is also a culture issue 19 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Looking ahead for CM • CM in Product Life-Cycle Management (PLM) tools – Become more data-centric and network-centric – Virtual Design and Manufacturing – Knowledge and Intelligence 20 Ref: Airbus Configuration © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics SYSTEM ENGINEERING & INTEGRATION 21 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics System Integration | mission • Scope: integrate data and information, satisfying the following requirements – Performance – Reliability and maintenance – Airworthiness requirements – Low cost and on time 22 • Mission: improve competitiveness by adopting an integrated and efficient process, methods, and tools along the whole product life cycle © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Example | AIRBUS production distribution 23 AIRBUS-France AIRBUS-Deutschland AIRBUS-UK Belairbus AIRBUS-España Production sharing by the Centres of Competence. Distributed engineering and manufacture ©Airbus © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics System Integration | what (1) 24 Design flowchart

2018/5/16 System Integration what(2) 园上声克大学 System Integration what (3) 国上清大学 aircraft hierarchy definition Integration testing approach orn enin Song System Integration I what (4) 圈上活大坐 System Integration principles and methods 园上活道大整 Store integration Top-down approach in establishing the technical specification Airworthiness a priority Cost and schedulecontrol (WBS) Use of master model in the design process Multidisciplinary approach 。 Digital mock-up Human research using virtual reality Process integration Networked collaboration environment System Integration System Integration Top-down Approach 国上清大学 Cost and Schedule Control 园上海发大坐 Design specification in top down manner Work Breakdown Structure(WBS) breakdown structure or the WBs Balance between technology innovation, performance and cost Use of mature t onties.and measurement and contrh 网 四 密岛密 -Dr.W(enbin Song 5

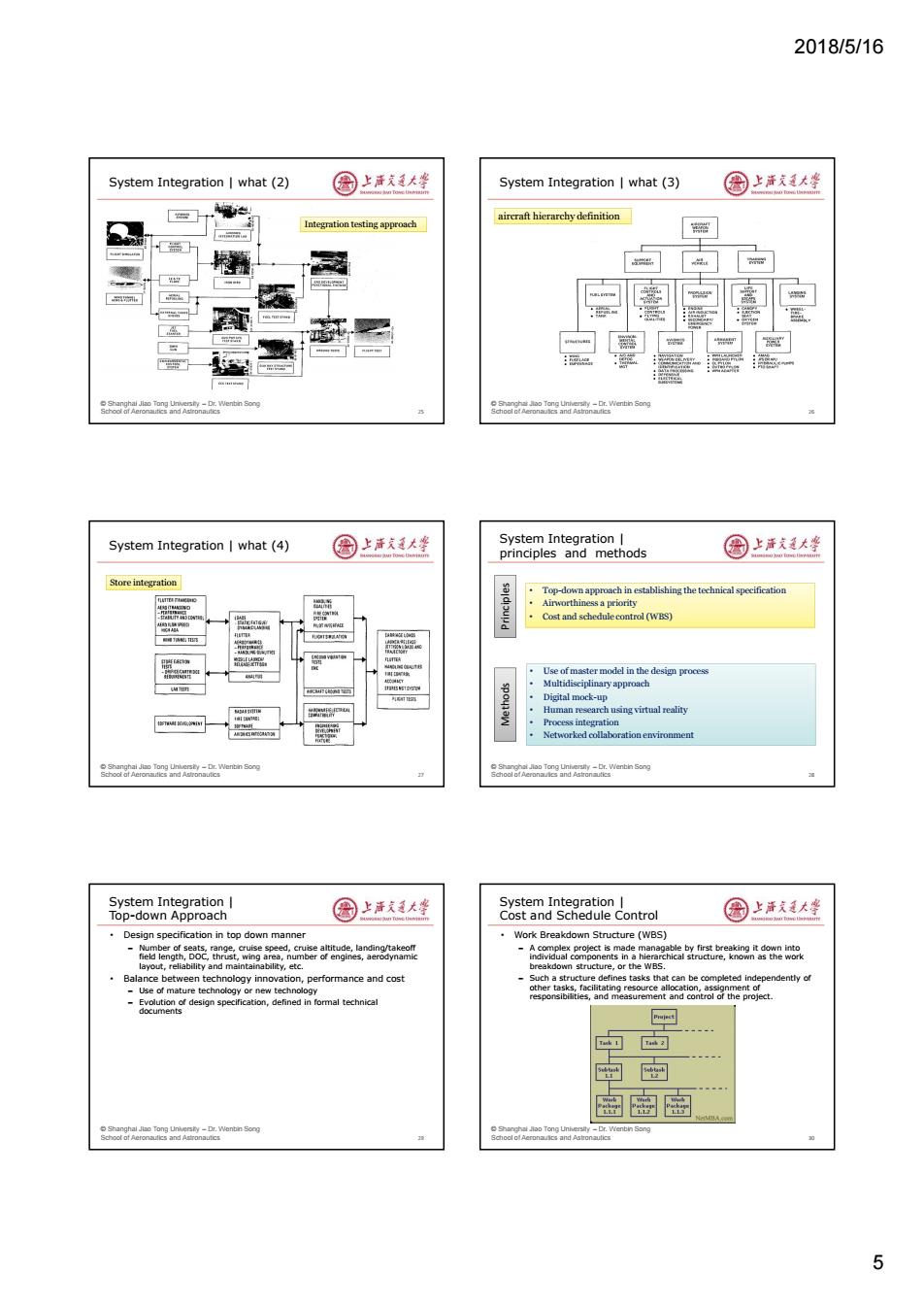

2018/5/16 5 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics System Integration | what (2) 25 Integration testing approach © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics System Integration | what (3) 26 aircraft hierarchy definition © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics System Integration | what (4) 27 Store integration © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics System Integration | principles and methods 28 • Top-down approach in establishing the technical specification • Airworthiness a priority • Cost and schedule control (WBS) • Use of master model in the design process • Multidisciplinary approach • Digital mock-up • Human research using virtual reality • Process integration • Networked collaboration environment Principles Methods © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics System Integration | Top-down Approach • Design specification in top down manner – Number of seats, range, cruise speed, cruise altitude, landing/takeoff field length, DOC, thrust, wing area, number of engines, aerodynamic layout, reliability and maintainability, etc. • Balance between technology innovation, performance and cost – Use of mature technology or new technology – Evolution of design specification, defined in formal technical documents 29 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics System Integration | Cost and Schedule Control • Work Breakdown Structure (WBS) – A complex project is made managable by first breaking it down into individual components in a hierarchical structure, known as the work breakdown structure, or the WBS. – Such a structure defines tasks that can be completed independently of other tasks, facilitating resource allocation, assignment of responsibilities, and measurement and control of the project. 30

2018/5/16 System Integration Compatibility Issues 圆上清文大华 Interactions Between Disciplines 国上清大学 Building the data link between discipline analysis module of various fidelity Structure,space,mechanic systems M Space consistency GAP -Mechanic systems GAP GAP Environmental issues CFD AN Example Evolution of Models in Design Process 国上活大蜂 Digital Mock-Up? 圆上洋发廷大坐 What is a Digital Mock-Up? Why using a Digital Mock-Up? -A Digital Mock-Up is a To support the analysis of the meea8cgtal models that represents partially or globally a product -DMU is used to ease design product(airframe, understanding,validation, nic,-.) mation, -DMU is used to replace CAD partially or totally the physical FEA CAD Examples Human simulation. 国上洋大坐 Examples Process Definition Validation 园上海发大坐 Validate an assembly operation with engineers in the scene Validation of the assembly of a big structure. 5 Validate th ised in g tool Con Tong Uni ty -Dr.Wenbin Song 6

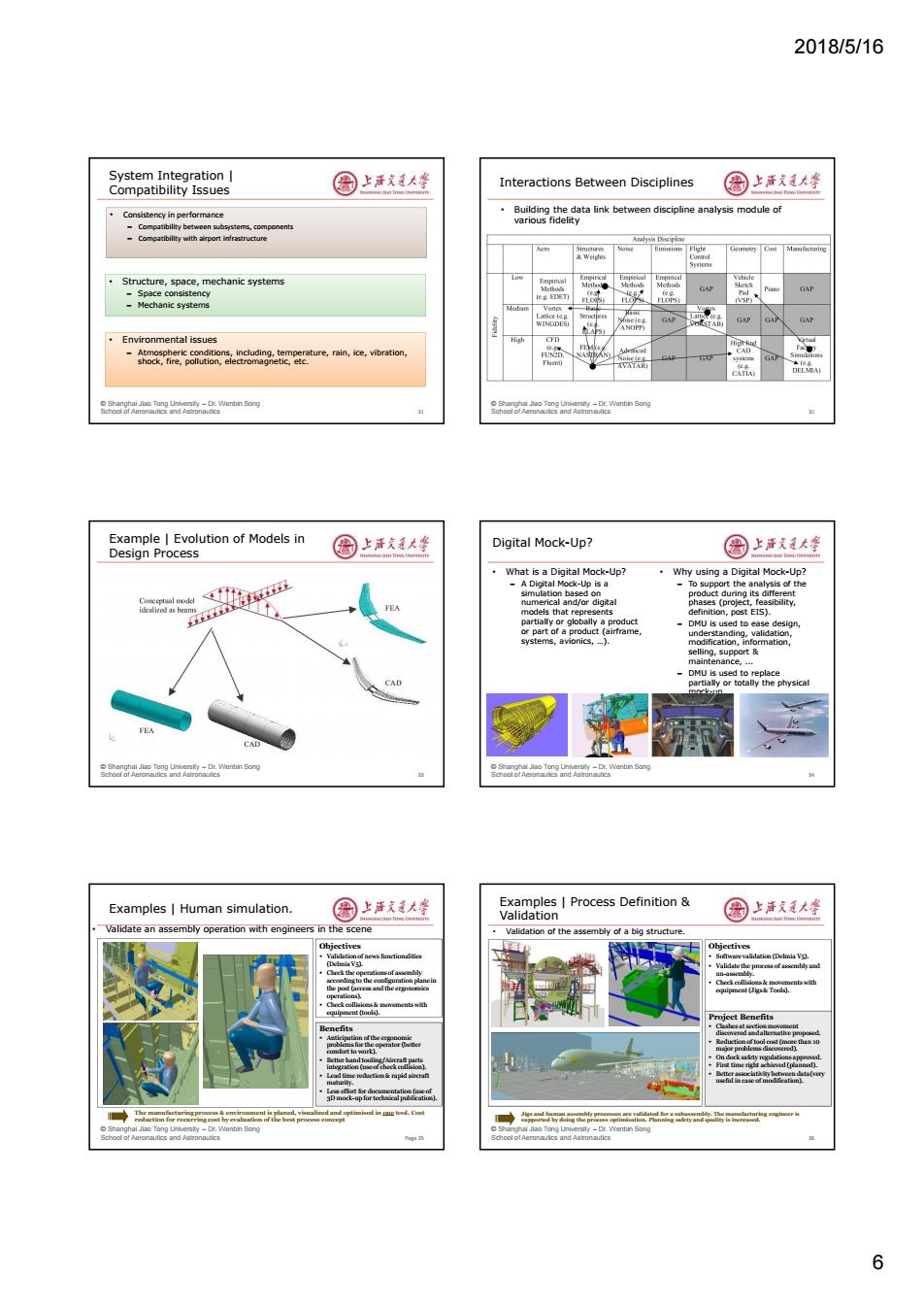

2018/5/16 6 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics System Integration | Compatibility Issues • Consistency in performance – Compatibility between subsystems, components – Compatibility with airport infrastructure 31 • Structure, space, mechanic systems – Space consistency – Mechanic systems • Environmental issues – Atmospheric conditions, including, temperature, rain, ice, vibration, shock, fire, pollution, electromagnetic, etc. © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Interactions Between Disciplines • Building the data link between discipline analysis module of various fidelity 32 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Example | Evolution of Models in Design Process 33 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Digital Mock-Up? • What is a Digital Mock-Up? – A Digital Mock-Up is a simulation based on numerical and/or digital models that represents partially or globally a product or part of a product (airframe, systems, avionics, …). • Why using a Digital Mock-Up? – To support the analysis of the product during its different phases (project, feasibility, definition, post EIS). – DMU is used to ease design, understanding, validation, modification, information, selling, support & maintenance, ... – DMU is used to replace partially or totally the physical mock-up. 34 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Examples | Human simulation. Page 35 • Validate an assembly operation with engineers in the scene The manufacturing process & environment is planed, visualized and optimised in one tool. Cost reduction for recurring cost by evaluation of the best process concept Objectives • Validation of news functionalities (Delmia V5). • Check the operations of assembly according to the configuration plane in the post (access and the ergonomics operations). • Check collisions & movements with equipment (tools). Benefits • Anticipation of the ergonomic problems for the operator (better comfort to work). • Better hand tooling/Aircraft parts integration (use of check collision). • Lead time reduction & rapid aircraft maturity. • Less effort for documentation (use of 3D mock-up for technical publication). © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Examples | Process Definition & Validation • Validation of the assembly of a big structure. 36 Objectives • Software validation (Delmia V5). • Validate the process of assembly and un-assembly. • Check collisions & movements with equipment (Jigs & Tools). Project Benefits • Clashes at section movement discovered and alternative proposed. • Reduction of tool cost (more than 10 major problems discovered). • On dock safety regulations approved. • First time right achieved (planned). • Better associativity between data (very useful in case of modification). Jigs and human assembly processes are validated for a subassembly. The manufacturing engineer is supported by doing the process optimisation. Planning safety and quality is increased

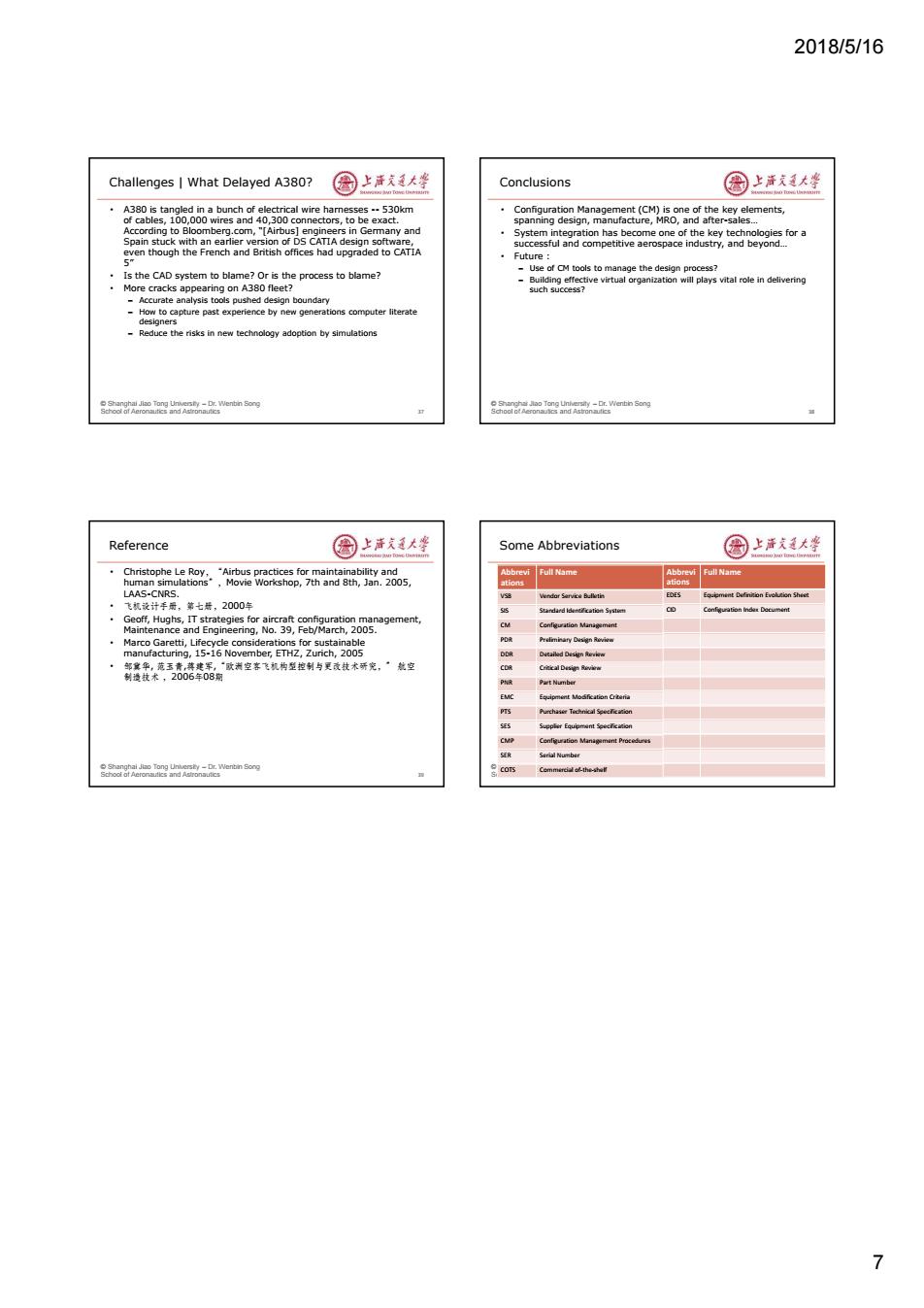

2018/5/16 Challenges What Delayed A380? 因上声克大警 Conclusions 国上活大学 A380 is tangled in a bunch of electrical wire hamnesses--530km Configuration Management(CM)is one of the key elements, of cables,100,000 wires and 40.300 connectors.to be exact. spanning design,manufacture,MRO,and after-sales. According to Bloomberg.com,"[Airbus]engineers in Germany and Spain stuck with an earlier version of DS CATIA design software System egrat tion has become one of he n ecoryora o British off ·Future: -Use of CM tools to manage the design process? Is the CAD system to blame?Or is the process to blame? -Building effective virtual organization will plays vital role in delivering More cracks appearing on A380 fleet? such success? -Accurate analysis tools pushed design boundary -How to capture past experience by new generations computer literate designers -Reduce the risks in new technology adoption by simulations orn enin Song Reference 国上活道大峰 Some Abbreviations 国上清大坐 Christophe Le Roy, "Airbus practices for maintainability and Abbrevi Full Name AbbreviFull Name human simulations Movie Workshop,7th and 8th,Jan.2005, ations ations LAAS-CNRS. vsa Vendor Service B.llotin EDES Eqemint Defntion Evolution Sheet ·飞就设计手册,第七册,2000年 Stardard ldentfcation Systoem CM Marco Garetti,Lifecycle considerations for sustainable PDR manufacturing,15-16 November,ETHZ,Zurich,2005 DDR O说ailed Design Reviw 邮冀华,范玉青,蒋建军,“欧满空客飞机构型控制与更成技术研究,·越空 CDR 制造技术,2006年08物 PNR Part Number EMC PTS Purha Tecnieicon S级5 经R Cemmereil of-the-she 7

2018/5/16 7 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Challenges | What Delayed A380? • A380 is tangled in a bunch of electrical wire harnesses -- 530km of cables, 100,000 wires and 40,300 connectors, to be exact. According to Bloomberg.com, “[Airbus] engineers in Germany and Spain stuck with an earlier version of DS CATIA design software, even though the French and British offices had upgraded to CATIA 5” • Is the CAD system to blame? Or is the process to blame? • More cracks appearing on A380 fleet? – Accurate analysis tools pushed design boundary – How to capture past experience by new generations computer literate designers – Reduce the risks in new technology adoption by simulations 37 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Conclusions • Configuration Management (CM) is one of the key elements, spanning design, manufacture, MRO, and after-sales… • System integration has become one of the key technologies for a successful and competitive aerospace industry, and beyond… • Future : – Use of CM tools to manage the design process? – Building effective virtual organization will plays vital role in delivering such success? 38 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Reference • Christophe Le Roy,“Airbus practices for maintainability and human simulations”,Movie Workshop, 7th and 8th, Jan. 2005, LAAS-CNRS. • 飞机设计手册,第七册,2000年 • Geoff, Hughs, IT strategies for aircraft configuration management, Maintenance and Engineering, No. 39, Feb/March, 2005. • Marco Garetti, Lifecycle considerations for sustainable manufacturing, 15-16 November, ETHZ, Zurich, 2005 • 邹冀华, 范玉青,蒋建军,“欧洲空客飞机构型控制与更改技术研究,” 航空 制造技术 ,2006年08期 39 © Shanghai Jiao Tong University – Dr. Wenbin Song School of Aeronautics and Astronautics Some Abbreviations Abbrevi ations Full Name VSB Vendor Service Bulletin SIS Standard Identification System CM Configuration Management PDR Preliminary Design Review DDR Detailed Design Review CDR Critical Design Review PNR Part Number EMC Equipment Modification Criteria PTS Purchaser Technical Specification SES Supplier Equipment Specification CMP Configuration Management Procedures SER Serial Number COTS Commercial of-the-shelf 40 Abbrevi ations Full Name EDES Equipment Definition Evolution Sheet CID Configuration Index Document