先进材料疑固实验室 路 Laboratory of Advanced Materials Solidification 1896 1920 1987 2006 Solidification of single phase alloys(3) Dr.Mingxu Xia anced Mate 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

1896 1920 1987 2006 Solidification of single phase alloys (3) Dr. Mingxu Xia

先进材料疑固实验室 References Laboratory of Advanced Materials Solidification M.C.Flemings,凝固过程 W.Kurz,凝固原理 介万奇,凝固技术 JA Dantzig and M Rappaz,Solidification r of pavanced 上降充通大学 SHANGHAI JIAO TONG UNIVERSITY

References M.C.Flemings, 凝固过程 W.Kurz,凝固原理 介万奇,凝固技术 JA Dantzig and M Rappaz, Solidification

先进材料疑固实验室 OUTLINE Laboratory of Advanced Materials Solidification Solute Redistribution Solute distribution coefficient Solute redistribution in equilibrium state Solute redistribution in non-equilibrium state Solute distribution in front of S/L interface Application:Zone melting Morphology Instability of a S/L interface Constitutional undercooling Morphological instability of a S/L interface Solidification microstructure:Cells and dendrites ·Constrained growth Preferred growth direction ·Dendrite arm spacing Formation of equiaxed grains 。Cast microstructure 上降充通大学 SHANGHAI JIAO TONG UNIVERSITY

OUTLINE Solute Redistribution • Solute distribution coefficient • Solute redistribution in equilibrium state • Solute redistribution in non-equilibrium state • Solute distribution in front of S/L interface • Application: Zone melting Morphology Instability of a S/L interface • Constitutional undercooling • Morphological instability of a S/L interface • Solidification microstructure: Cells and dendrites • Constrained growth • Preferred growth direction • Dendrite arm spacing • Formation of equiaxed grains • Cast microstructure

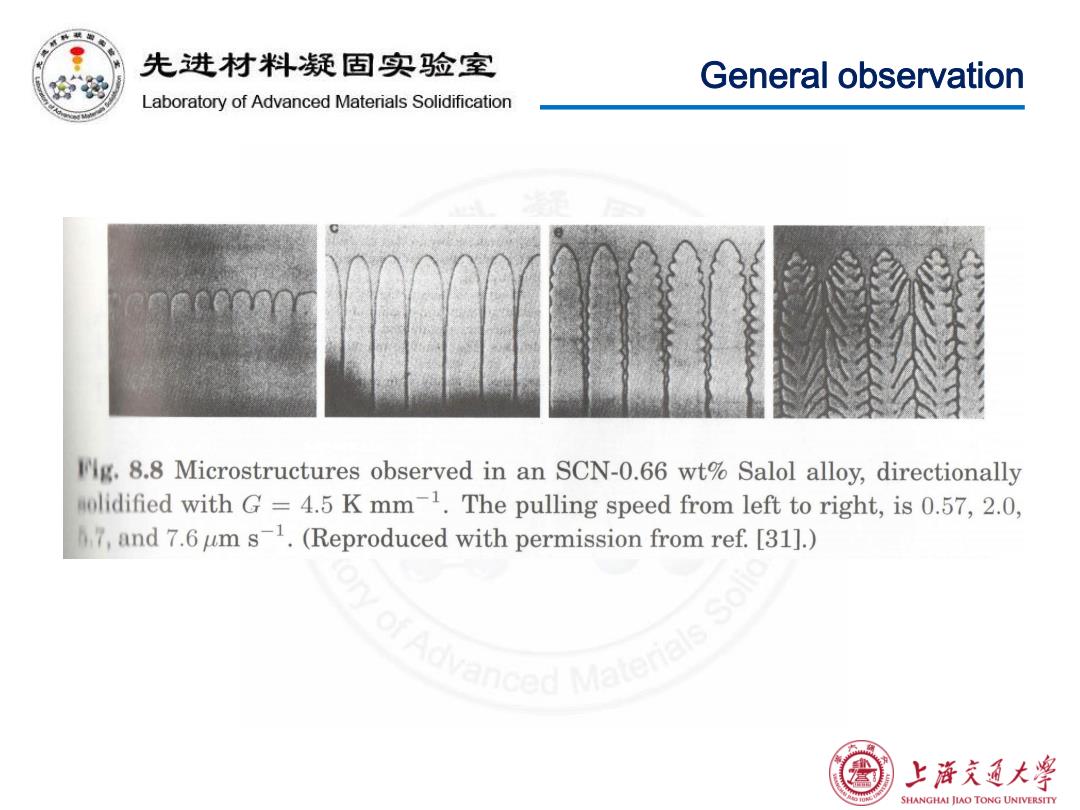

先进材料疑固实验室 General observation Laboratory of Advanced Materials Solidification Ig.8.8 Microstructures observed in an SCN-0.66 wt%Salol alloy,directionally olidified with G=4.5 K mm-1.The pulling speed from left to right,is 0.57,2.0, 7,and 7.6 um s-1.(Reproduced with permission from ref.[31].) anced Mat 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

General observation

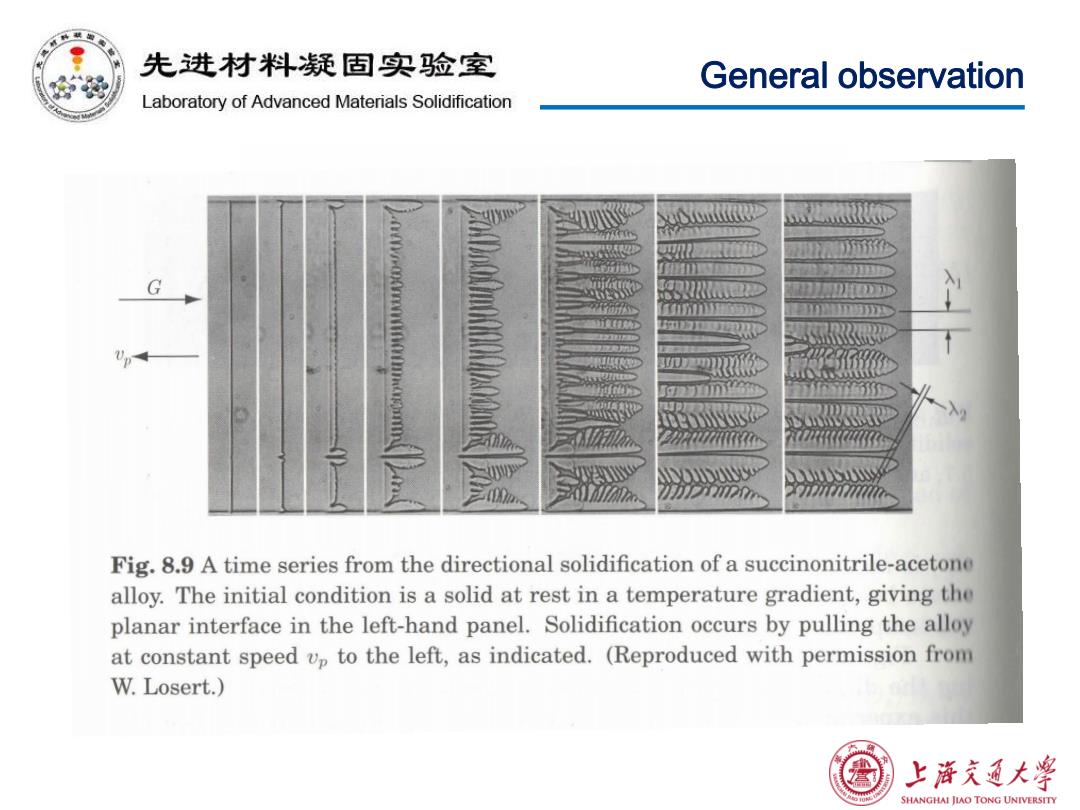

先进材料疑固实验室 General observation Laboratory of Advanced Materials Solidification Fig.8.9 A time series from the directional solidification of a succinonitrile-acetone alloy.The initial condition is a solid at rest in a temperature gradient,giving the planar interface in the left-hand panel.Solidification occurs by pulling the alloy at constant speed vp to the left,as indicated.(Reproduced with permission from W.Losert.) 上游充通大学 SHANGHAI JIAO TONG UNIVERSITY

General observation

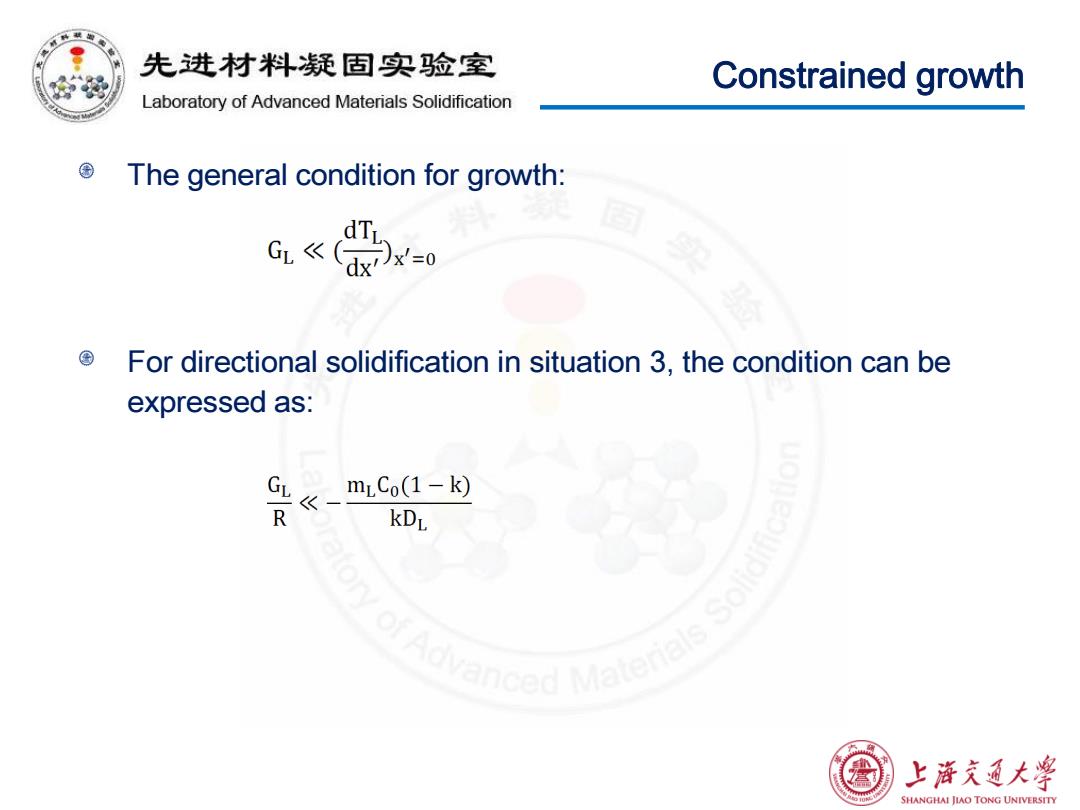

先进材料疑固实验室 Constrained growth Laboratory of Advanced Materials Solidification The general condition for growth: For directional solidification in situation 3,the condition can be expressed as: - LCo(1-k) R kDL of Advanced Materials Solic 上降充通大学 SHANGHAI JIAO TONG UNIVERSITY

Constrained growth The general condition for growth: For directional solidification in situation 3, the condition can be expressed as:

先进材料疑固实验室 Constrained growth Laboratory of Advanced Materials Solidification The initiation of dendritic growth: Breakdown of unstable planar S/L interface perturbations. The tips of perturbations grow faster than their depressions due to constitutional undercooling the perturbations change from sinusoidal to cellular. The cell growth direction deviates towards the preferred crystallographic direction. For metals with a cubic crystal structure,this direction is . nced 上游充〔大¥ SHANGHAI JIAO TONG UNIVERSITY

Constrained growth The initiation of dendritic growth: Breakdown of unstable planar S/L interface perturbations. The tips of perturbations grow faster than their depressions due to constitutional undercooling the perturbations change from sinusoidal to cellular. The cell growth direction deviates towards the preferred crystallographic direction. For metals with a cubic crystal structure, this direction is

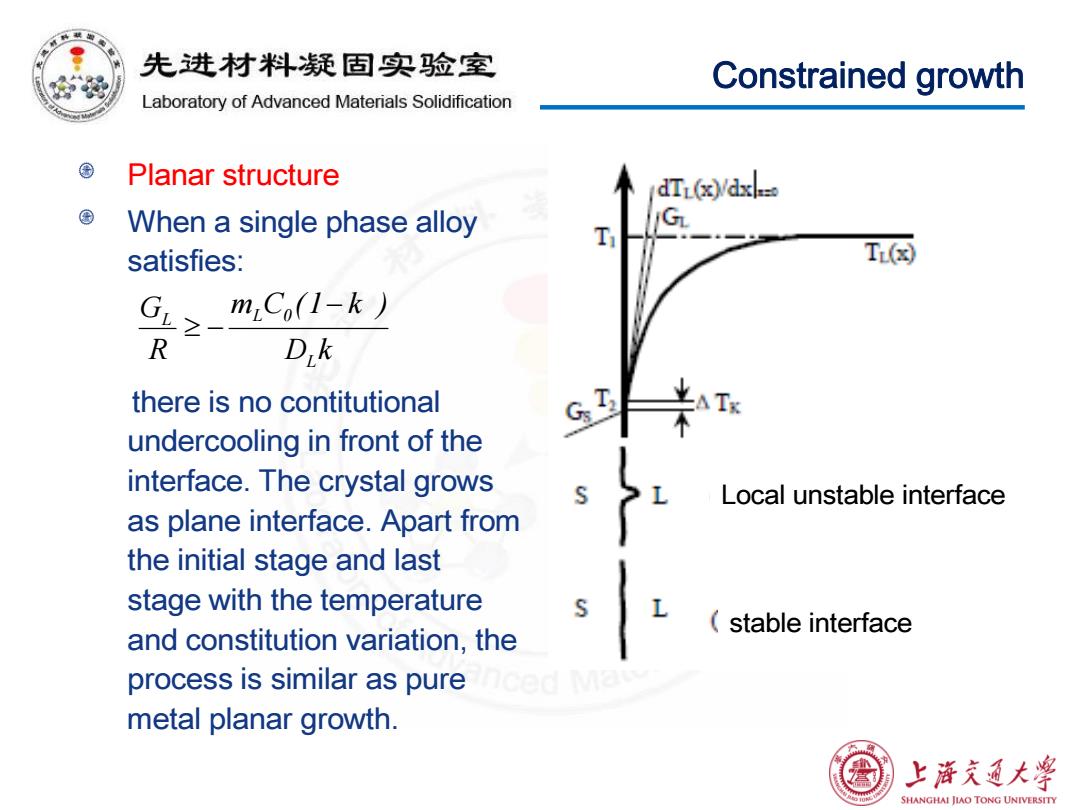

先进材料疑固实验室 Constrained growth Laboratory of Advanced Materials Solidification Planar structure dTL(x)/dxl When a single phase alloy G T satisfies: T(⑧ G>- mCo(1-k R Dk there is no contitutional undercooling in front of the interface.The crystal grows Local unstable interface as plane interface.Apart from the initial stage and last stage with the temperature stable interface and constitution variation,the process is similar as pure metal planar growth. 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

Planar structure When a single phase alloy satisfies: there is no contitutional undercooling in front of the interface. The crystal grows as plane interface. Apart from the initial stage and last stage with the temperature and constitution variation, the process is similar as pure metal planar growth. Constrained growth D k m C (1 k ) R G L L L 0 Local unstable interface stable interface

先进材料疑固实验室 Constrained growth Laboratory of Advanced Materials Solidification For pure metal or single phase alloy,the crystal growth speed can be deduced from the heat transfer at interface: GsAs =GLAL RpL where As,AL are the thermal conductivity coefficient of solid and liquid.Gs and GL are the temperature gradient in solid and in liquid, respectively.p is the area density and L is latent heat. vanced Materd 上降充通大学 SHANGHAI JIAO TONG UNIVERSITY

Constrained growth For pure metal or single phase alloy, the crystal growth speed can be deduced from the heat transfer at interface: where λS , λL are the thermal conductivity coefficient of solid and liquid. Gs and GL are the temperature gradient in solid and in liquid, respectively. ρ is the area density and L is latent heat

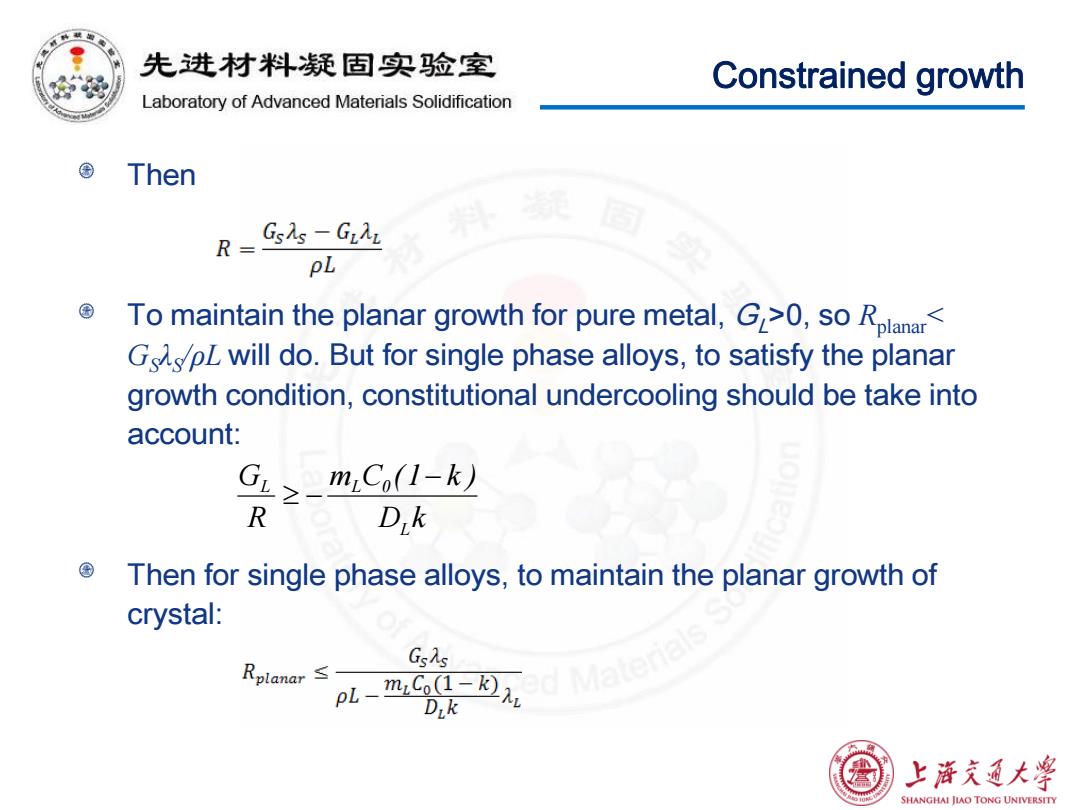

先进材料疑固实验室 Constrained growth Laboratory of Advanced Materials Solidification Then R= GsAs-GLAL pL To maintain the planar growth for pure metal,G>0,so Rplanar GpL will do.But for single phase alloys,to satisfy the planar growth condition,constitutional undercooling should be take into account: 2- miCo(1-k) R Dik Then for single phase alloys,to maintain the planar growth of crystal: GsAs Rplanar≤一 - miCo1-R d Me Dik 上游充通大学 SHANGHAI JIAO TONG UNIVERSITY

Constrained growth Then To maintain the planar growth for pure metal, GL>0, so Rplanar< GS λS /ρL will do. But for single phase alloys, to satisfy the planar growth condition, constitutional undercooling should be take into account: Then for single phase alloys, to maintain the planar growth of crystal: D k m C (1 k ) R G L L L 0