先进材料疑固实验室 Laboratory of Advanced Materials Solidification 1896 1920 1987 2006 Metal Casting Technology (3) Dr.Mingxu Xia ® 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

1896 1920 1987 2006 Metal Casting Technology (3) Dr. Mingxu Xia

先进材料疑固实验室 Outline Laboratory of Advanced Materials Solidification Introduction Casting practice Design considering in casting Design for expendable-mold casting Major casting processes ory of Advanced M 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

Outline Introduction Casting practice Design considering in casting Design for expendable-mold casting Major casting processes

先进材料疑固实验室 Laboratory of Advanced Materials Solidification 1896 1920 1987 2006 SINGLE CRYSTAL GROWTH 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

1896 1920 1987 2006 SINGLE CRYSTAL GROWTH

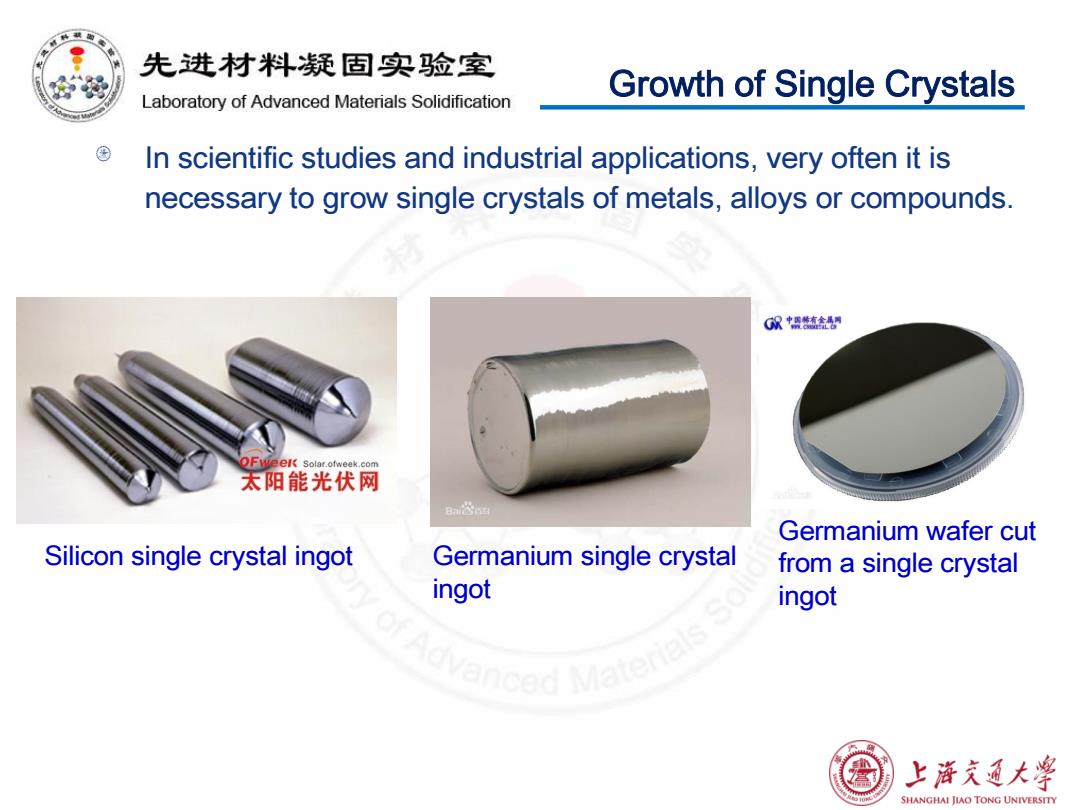

先进材料疑固实验室 Growth of Single Crystals Laboratory of Advanced Materials Solidification In scientific studies and industrial applications,very often it is necessary to grow single crystals of metals,alloys or compounds. GR中摄随会 Fweel Solar.ofweek.com 太阳能光伏网 Germanium wafer cut Silicon single crystal ingot Germanium single crystal from a single crystal ingot ingot 上浒充通大 SHANGHAI JIAO TONG UNIVERSITY

Growth of Single Crystals In scientific studies and industrial applications, very often it is necessary to grow single crystals of metals, alloys or compounds. Silicon single crystal ingot Germanium single crystal ingot Germanium wafer cut from a single crystal ingot

先进材料疑固实验室 Growth of Single Crystals Laboratory of Advanced Materials Solidification Typical methods of growing single crystals: Normal freezing method:move the crucible(or boat)containing molten metal or alloy relative to the furnace in one direction to allow the crystal grow in only one direction. If the crucible is vertical,the method is also called Bridgeman method. Zone melting method:melt a small part of an ingot and move the molten zone along the ingot from one end to the other end. Sometime,zone melting is done without using crucible,in this case,the method is also called floating zone method. Crystal pulling method(also called Czochraski method):pull a crystal seed from a pool of liquid. 上游充通大学 SHANGHAI JIAO TONG UNIVERSITY

Typical methods of growing single crystals: Normal freezing method: move the crucible (or boat) containing molten metal or alloy relative to the furnace in one direction to allow the crystal grow in only one direction. • If the crucible is vertical, the method is also called Bridgeman method. Zone melting method: melt a small part of an ingot and move the molten zone along the ingot from one end to the other end. • Sometime, zone melting is done without using crucible, in this case, the method is also called floating zone method. Crystal pulling method (also called Czochraski method): pull a crystal seed from a pool of liquid. Growth of Single Crystals

先进材料疑固实验室 Growth of Single Crystals Laboratory of Advanced Materials Solidification 000000000 SOLID LIQUID TO INERT GAS SOURCE OR VACUUM 0000Q0000 HEATING COILS CRYSTAL (a) TO INERT GAS SOURCE OR VACUUM .CRYSTAL WITHDRAWAL AND ROTATION CRYSTAL TO INERT GAS -FLOATING"LIQUID SOURCE OR ZONE VACUUM HEATING COILS 0000000000 8 8 0 LIQUID HEATING COILS (b) (c) FIGURE I-1 Examples of crystal-growing mcthods.(a)Boat mcthod;(b)crystal pulling; (c)floating zone. 上浒充通大淫 SHANGHAI JIAO TONG UNIVERSITY

Growth of Single Crystals

先进材料疑固实验室 Laboratory of Advanced Materials Solidification 1896 1920 1987 2006 UNIDIRECTIONAL SOLIDIFICATION 、a伦。 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

1896 1920 1987 2006 UNIDIRECTIONAL SOLIDIFICATION

先进材料疑固实验室 Unidirectional Solidification Laboratory of Advanced Materials Solidification Unidirectional solidification is a solidification process(or technology)in which thermal fields are controlled to only allow the crystal (or crystals)to grow along one direction. This technology is used to make parts such as turbine blades which consist of only columnar grains or a single crystal.Such microstructure can significantly improve the creep resistance of the parts. nced Matere 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

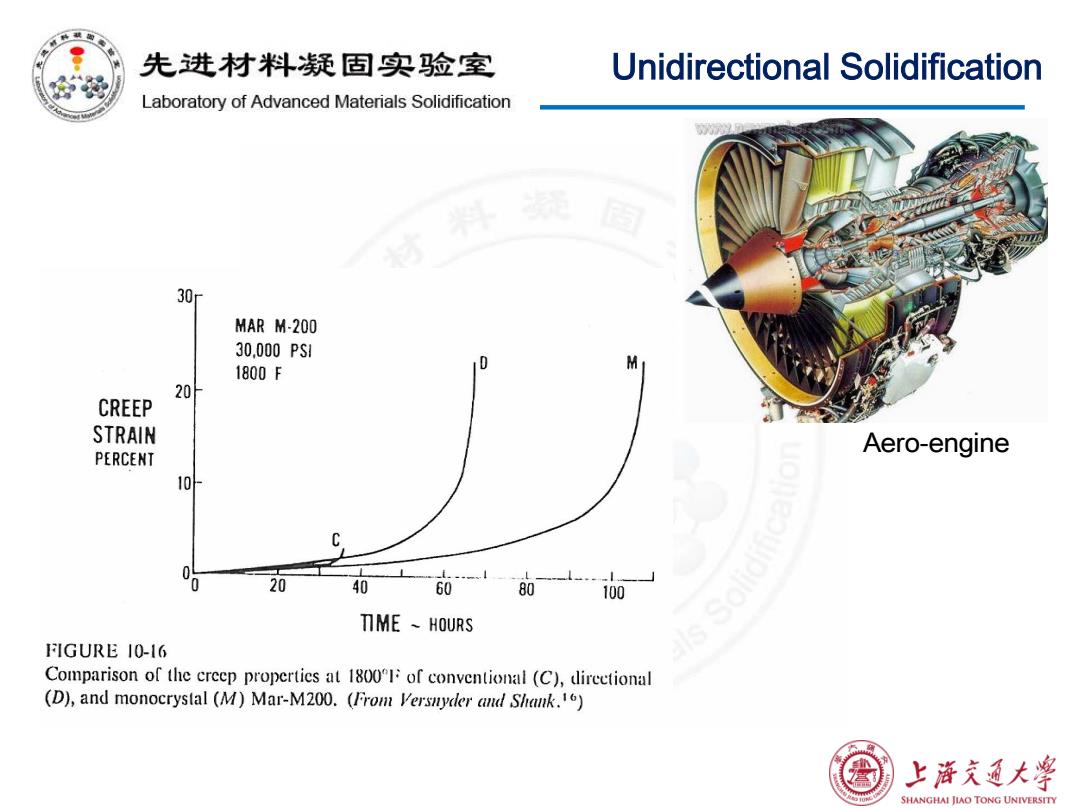

Unidirectional Solidification Unidirectional solidification is a solidification process (or technology) in which thermal fields are controlled to only allow the crystal (or crystals) to grow along one direction. This technology is used to make parts such as turbine blades which consist of only columnar grains or a single crystal. Such microstructure can significantly improve the creep resistance of the parts

先进材料疑固实验室 Unidirectional Solidification Laboratory of Advanced Materials Solidification 30r MAR M-200 30.000PS1 1800F M 20 CREEP STRAIN PERCENT Aero-engine 10 C 0 0 20 40 60 80 100 TIME HOURS FIGURE 10-16 Comparison of the creep properties at 18001:of conventional (C),directional (D),and monocrystal (M)Mar-M200.(From Versuyder and Shank.6) 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

Aero-engine Unidirectional Solidification

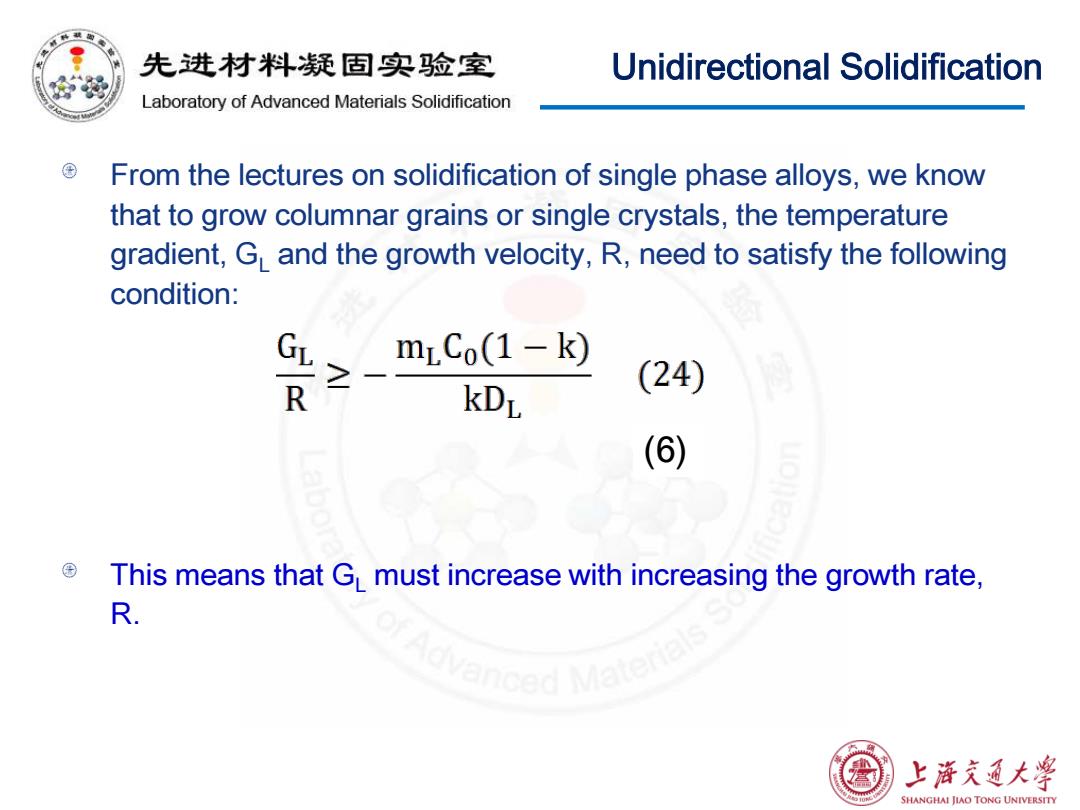

先进材料疑固实验室 Unidirectional Solidification Laboratory of Advanced Materials Solidification From the lectures on solidification of single phase alloys,we know that to grow columnar grains or single crystals,the temperature gradient,G and the growth velocity,R,need to satisfy the following condition: L mLCo(1-k) ≥ (24) kDL (6) This means that G must increase with increasing the growth rate, R. 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

From the lectures on solidification of single phase alloys, we know that to grow columnar grains or single crystals, the temperature gradient, GL and the growth velocity, R, need to satisfy the following condition: This means that GL must increase with increasing the growth rate, R. (6) Unidirectional Solidification