先进材料疑固实验室 Laboratory of Advanced Materials Solidification 1896 1920 1987 2006 Metal Casting Technology(1) Dr.Mingxu Xia anced Mat 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

1896 1920 1987 2006 Metal Casting Technology (1) Dr. Mingxu Xia

先进材料疑固实验室 OUTLINE Laboratory of Advanced Materials Solidification Introduction Casting practice Design considering in casting Design for expendable-mold casting Major casting processes ory of vanced Materials Solidif 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

OUTLINE Introduction Casting practice Design considering in casting Design for expendable-mold casting Major casting processes

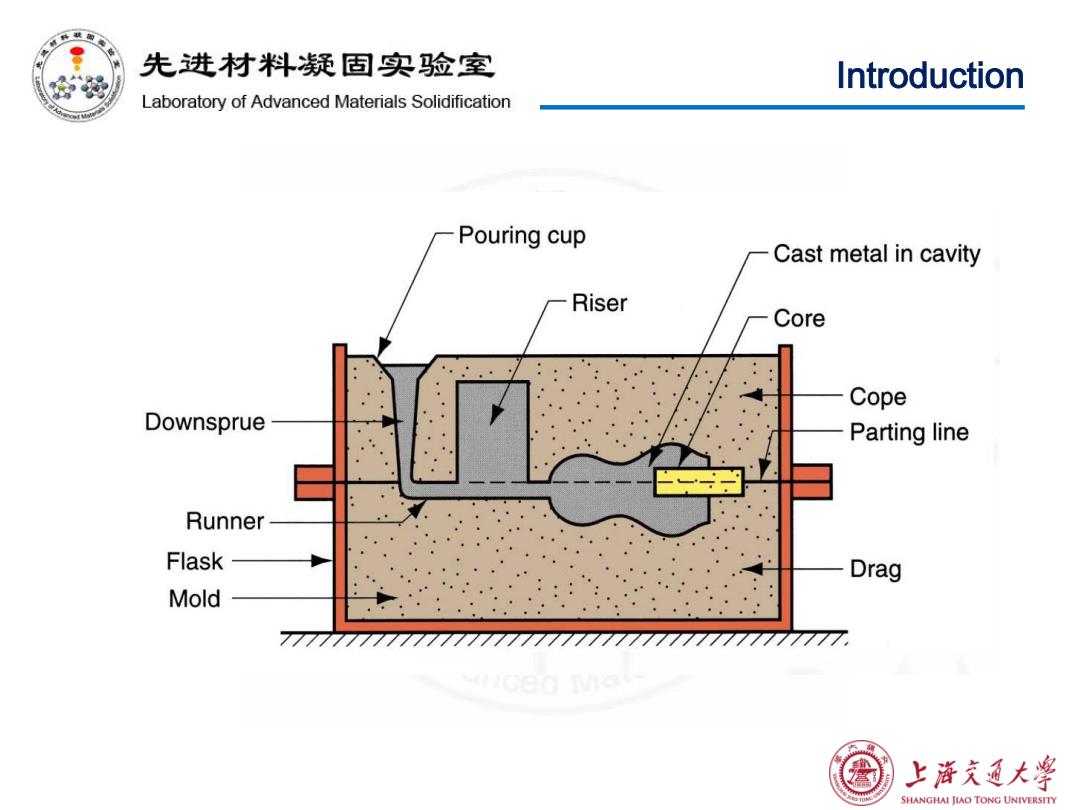

先进材料疑固实验室 Introduction Laboratory of Advanced Materials Solidification Pouring cup Cast metal in cavity Riser Core Cope Downsprue Parting line Runner Flask Drag Mold 77777777777777 77777777777777777 上游文通大学 SHANGHAI JIAO TONG UNIVERSITY

Introduction

先进材料疑固实验室 Introduction Laboratory of Advanced Materials Solidification So far,successful casting practice requires the proper control of a large number of variables: Characteristics of the metals (or alloys), ·Method of casting, ·Mold/die materials, ·Mold/die design,. ·Process parameters, The flow of the molten in the mold cavities, ·The gating systems, The rate of cooling,and The gases evolved all influence the quality of a casting 上海充通大¥ SHANGHAI JIAO TONG UNIVERSITY

Introduction So far, successful casting practice requires the proper control of a large number of variables: • Characteristics of the metals (or alloys) , • Method of casting, • Mold/die materials, • Mold/die design, • Process parameters, • The flow of the molten in the mold cavities, • The gating systems, • The rate of cooling, and • The gases evolved all influence the quality of a casting

先进材料疑固实验室 OUTLINE Laboratory of Advanced Materials Solidification Introduction Casting practice Design considering in casting Design for expendable-mold casting Major casting processes tory of vanced Materials Solidif 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

OUTLINE Introduction Casting practice Design considering in casting Design for expendable-mold casting Major casting processes

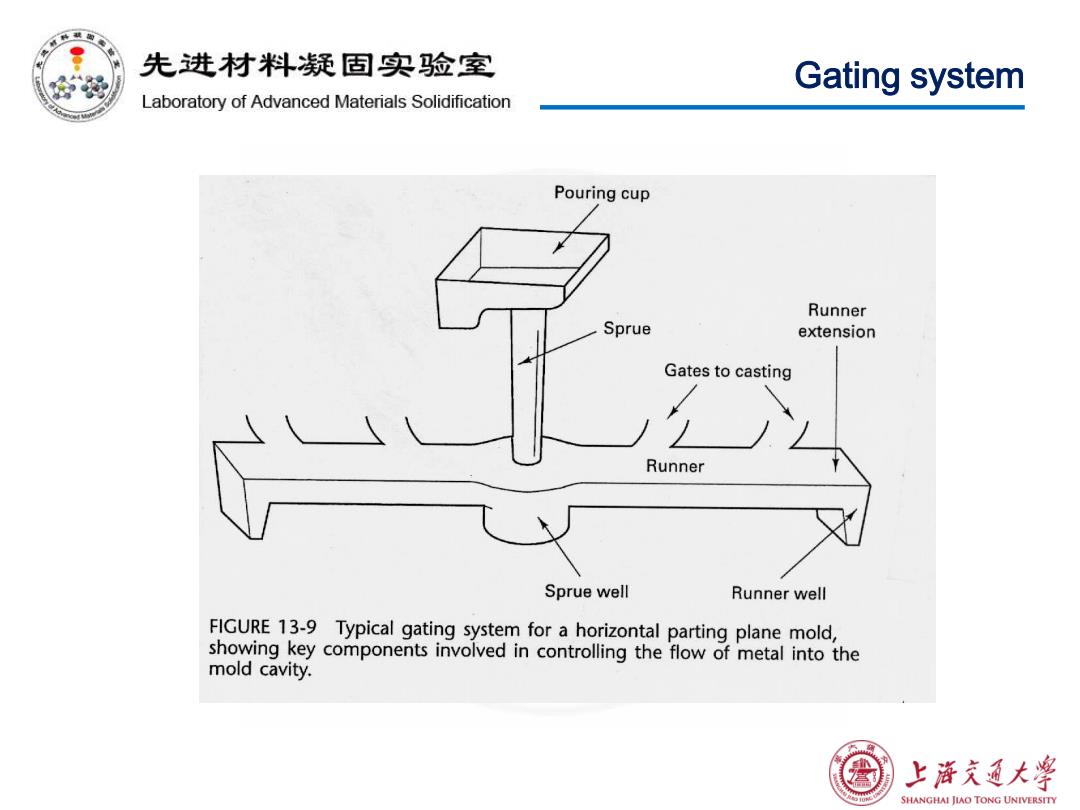

先进材料疑固实验室 Gating system Laboratory of Advanced Materials Solidification Pouring cup Runner Sprue extension 、 Gates to casting Runner Sprue well Runner well FIGURE 13-9 Typical gating system for a horizontal parting plane mold, showing key components involved in controlling the flow of metal into the mold cavity. 熟 上游文通大学 SHANGHAI JIAO TONG UNIVERSITY

Gating system

先进材料疑固实验室 Gating system Laboratory of Advanced Materials Solidification How to deliver liquid metal fast? By using a sufficient large cross sectional area; By using multiple runners. How to minimize turbulent flow? By using tapered sprue and runners. By bottom filling of the liquid into the mould cavity. e By regulating the change of cross sectional area of the channels according to fluid dynamics principles. 上浒充通大学 SHANGHAI JIAO TONG UNIVERSITY

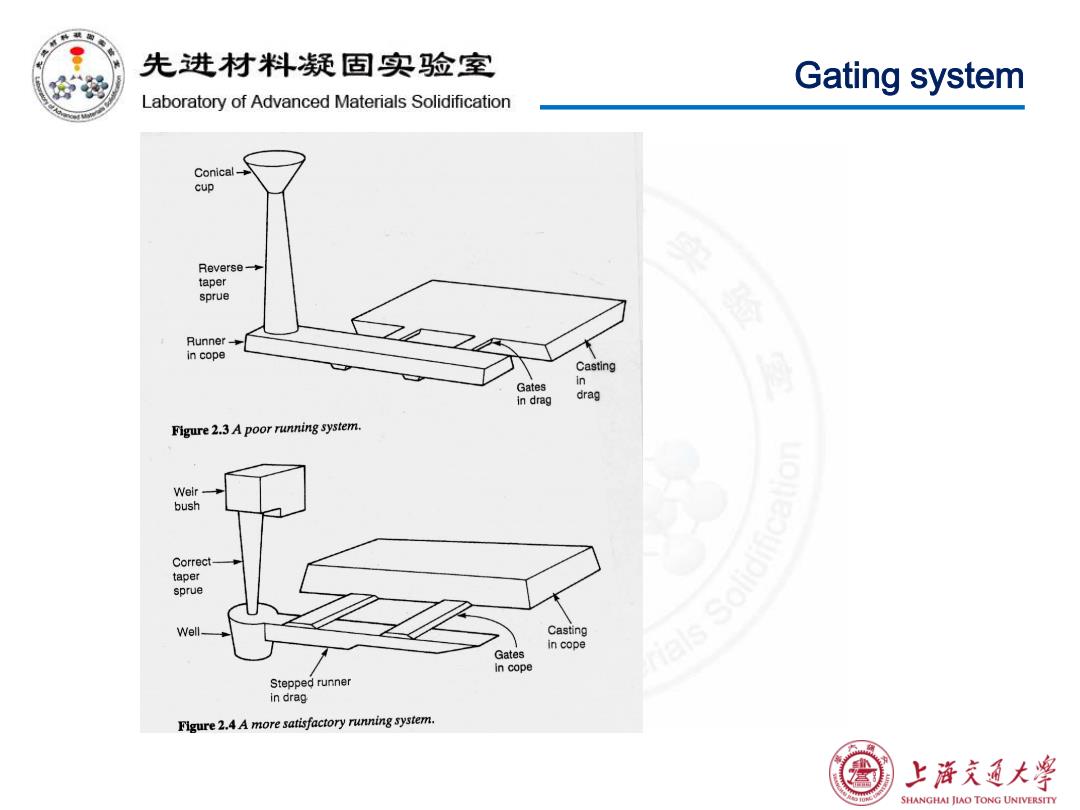

Gating system How to deliver liquid metal fast? • By using a sufficient large cross sectional area; • By using multiple runners. How to minimize turbulent flow? • By using tapered sprue and runners. • By bottom filling of the liquid into the mould cavity. • By regulating the change of cross sectional area of the channels according to fluid dynamics principles

先进材料疑固实验室 Gating system Laboratory of Advanced Materials Solidification How to keep dross and inclusion particles from entering mould cavity? ·By using dross traps. ·By using filters. ory of ivanced Materials Solid 上海充通大¥ SHANGHAI JIAO TONG UNIVERSITY

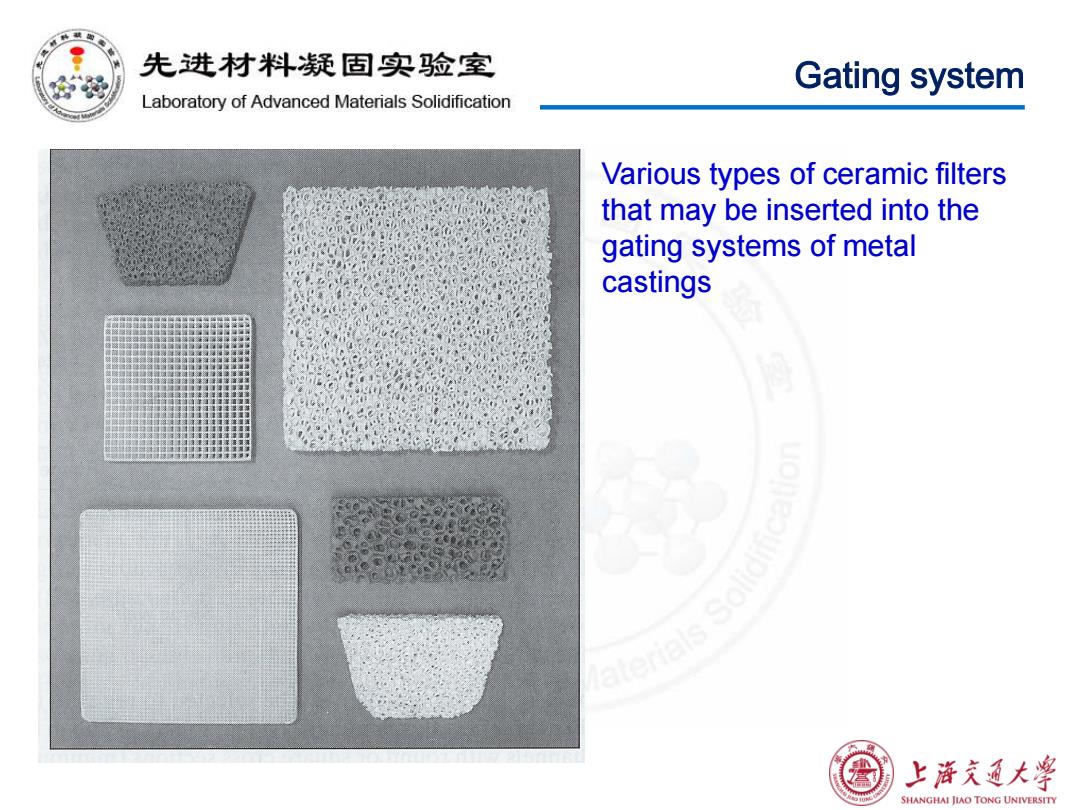

Gating system How to keep dross and inclusion particles from entering mould cavity? • By using dross traps. • By using filters

先进材料疑固实验室 Gating system Laboratory of Advanced Materials Solidification Various types of ceramic filters that may be inserted into the gating systems of metal castings 上浒充通大 SHANGHAI JIAO TONG UNIVERSITY

Gating system Various types of ceramic filters that may be inserted into the gating systems of metal castings

先进材料疑固实验室 Gating system Laboratory of Advanced Materials Solidification Conical- cup Reverse- taper sprue Runner in cope Casting in Gates in drag drag Figure 2.3 A poor running system. Weir bush Correct taper sprue Well Casting in cope Gates in cope Stepped runner in drag Figure 2.4 A more satisfactory running system. 上游文通大学 SHANGHAI JIAO TONG UNIVERSITY

Gating system