Outline Introduction Processing maps Elements of plastic theory Plastic deformation mechanism Recovery recrystallization

Outline Processing maps Plastic deformation mechanism Elements of plastic theory Recovery & recrystallization Introduction

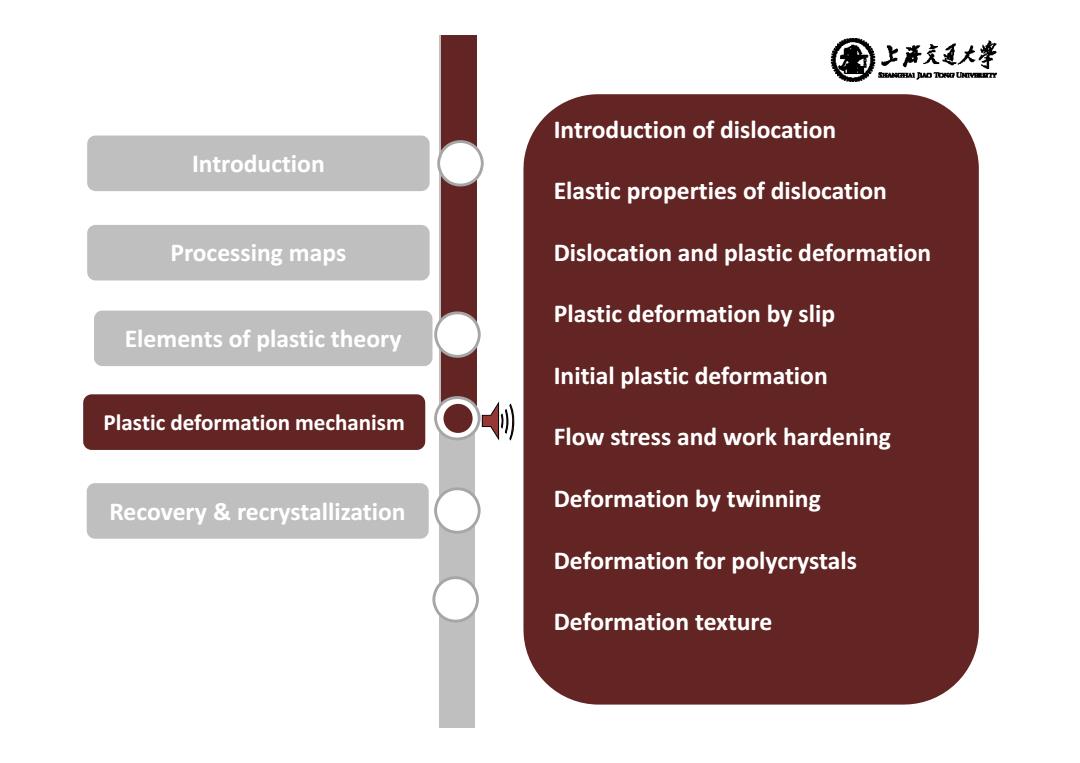

上清充通大学 SHEAMGRAI DUD TONO UHTVEREETTY Introduction of dislocation Introduction Elastic properties of dislocation Processing maps Dislocation and plastic deformation Plastic deformation by slip Elements of plastic theory Initial plastic deformation Plastic deformation mechanism ○) Flow stress and work hardening Recovery recrystallization Deformation by twinning Deformation for polycrystals Deformation texture

Introduction Elements of plastic theory Recovery & recrystallization 1 1 Plastic deformation mechanism Introduction of dislocation Elastic properties of dislocation Dislocation and plastic deformation Plastic deformation by slip Initial plastic deformation Flow stress and work hardening Deformation by twinning Deformation for polycrystals Deformation texture 1 1 Processing maps 1

Reference books 上清充通大¥ SHANCBHAI JUAO TONO UNTVEEETTY Mechanical Metallurgy* George E Dieter McGraw-Hill Book Company,London(1988) Introduction to Dislocations (further reading) D.Hull and D.J.Bacon Pergamon Press,Oxford(1984) Theory of Dislocations (advanced reading) J.P.Hirth and J.Lothe McGraw-Hill,New York (1968) Institute of Forming Technology Equipment 4

Reference books Institute of Forming Technology & Equipment 4 • Mechanical Metallurgy * George E Dieter McGraw‐Hill Book Company, London (1988) • Introduction to Dislocations (further reading) D. Hull and D.J. Bacon Pergamon Press, Oxford (1984) • Theory of Dislocations (advanced reading) J. P. Hirth and J. Lothe McGraw-Hill, New York (1968)

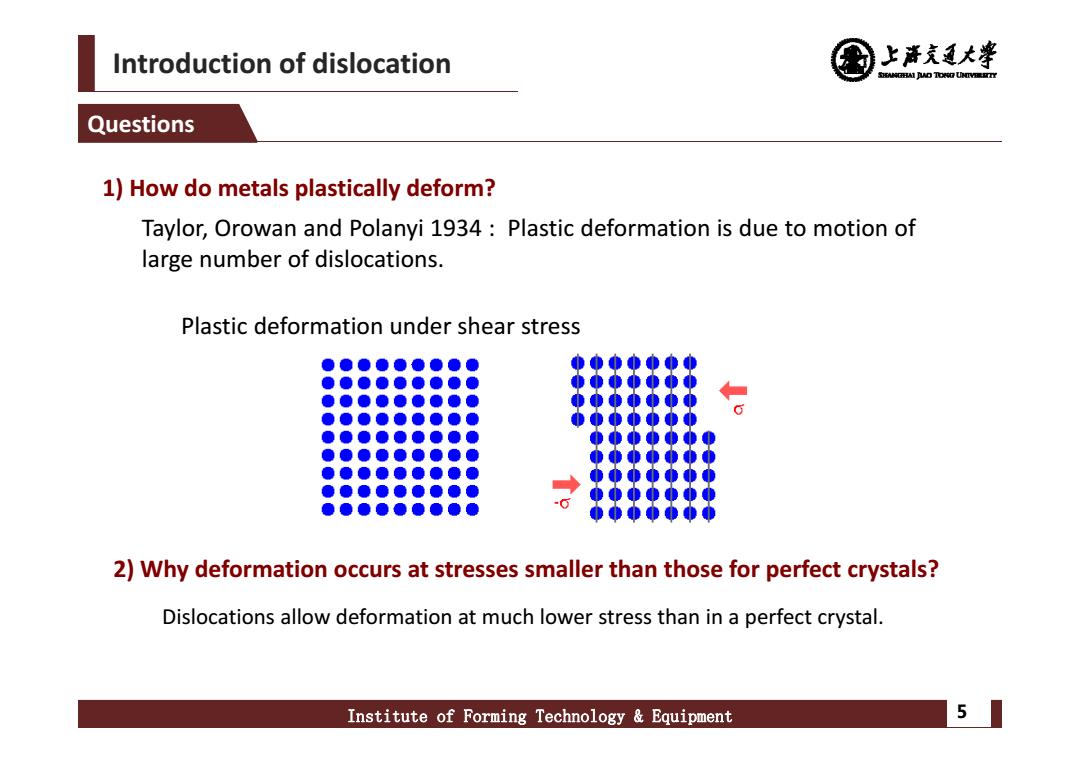

Introduction of dislocation 上产克大睾 SHEAMGHAI DUD TONO UHTVEREETTY Questions 1)How do metals plastically deform? Taylor,Orowan and Polanyi 1934:Plastic deformation is due to motion of large number of dislocations. Plastic deformation under shear stress ●●●●●●●●● 000ǜ00 ● 0o000●0 2)Why deformation occurs at stresses smaller than those for perfect crystals? Dislocations allow deformation at much lower stress than in a perfect crystal. Institute of Forming Technology Equipment 5

Introduction of dislocation Institute of Forming Technology & Equipment 5 Questions 1) How do metals plastically deform? Taylor, Orowan and Polanyi 1934 : Plastic deformation is due to motion of large number of dislocations. Plastic deformation under shear stress 2) Why deformation occurs at stresses smaller than those for perfect crystals? Dislocations allow deformation at much lower stress than in a perfect crystal

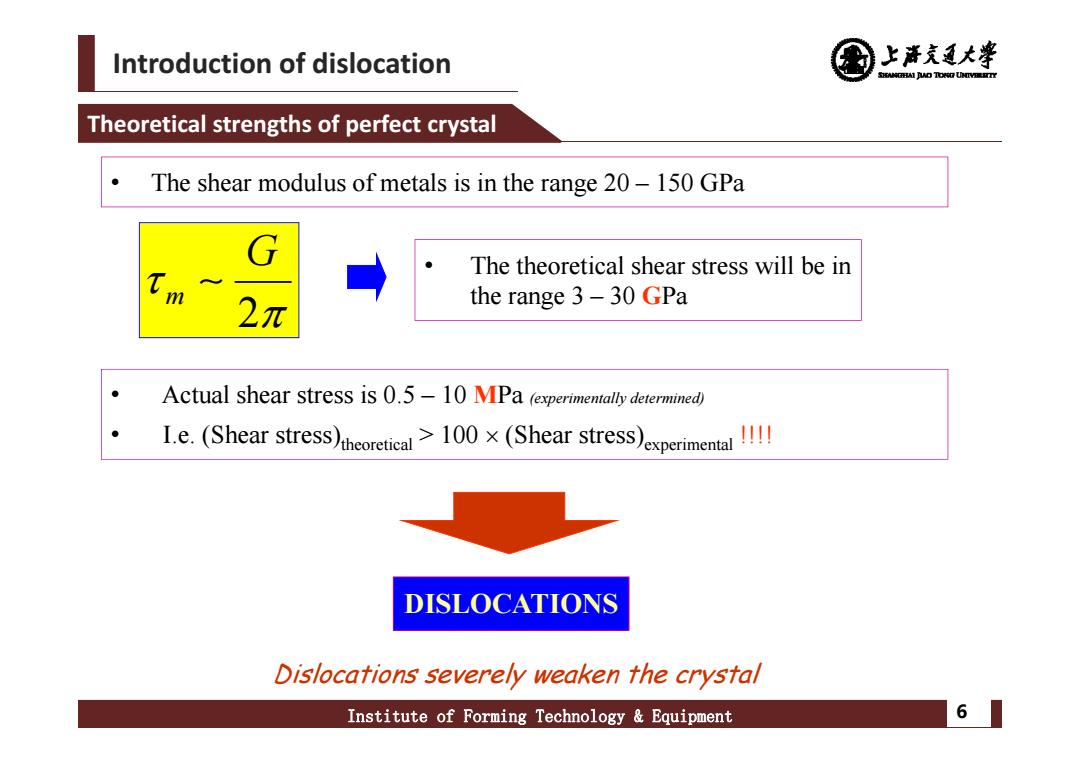

Introduction of dislocation 上清充通大学 SANCEAI JUO TO阳UY Theoretical strengths of perfect crystal The shear modulus of metals is in the range 20-150 GPa G The theoretical shear stress will be in 2元 the range 3-30 GPa Actual shear stress is 0.5-10 MPa (experimentally determined) I.e.(Shear stress)theoretical>100x(Shear stress)experimental DISLOCATIONS Dislocations severely weaken the crystal Institute of Forming Technology Equipment 61

Introduction of dislocation Institute of Forming Technology & Equipment 6 Theoretical strengths of perfect crystal 2 m G • The shear modulus of metals is in the range 20 – 150 GPa DISLOCATIONS • Actual shear stress is 0.5 – 10 MPa (experimentally determined) • I.e. (Shear stress)theoretical > 100 (Shear stress)experimental !!!! Dislocations severely weaken the crystal • The theoretical shear stress will be in the range 3 – 30 GPa

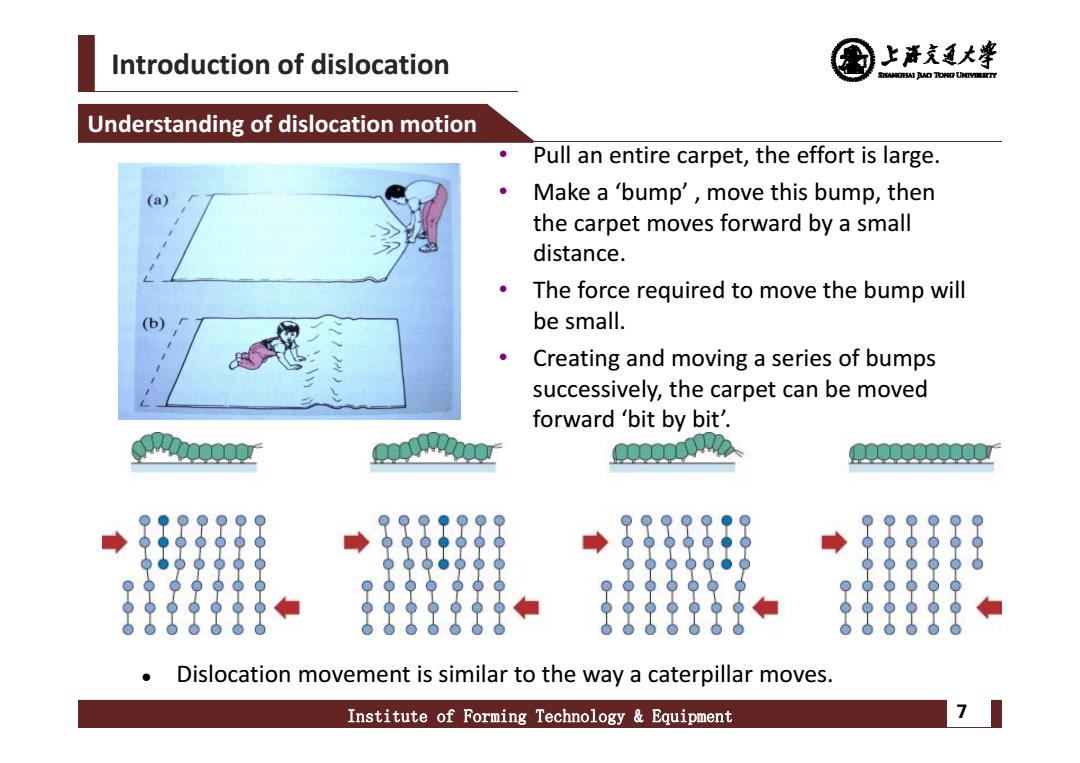

Introduction of dislocation 上清充通大学 SHEAMGHAI DUD TONO UHTVEREETTY Understanding of dislocation motion Pull an entire carpet,the effort is large. (a) Make a 'bump',move this bump,then the carpet moves forward by a small distance. The force required to move the bump will be small. Creating and moving a series of bumps successively,the carpet can be moved forward 'bit by bit'. Dislocation movement is similar to the way a caterpillar moves. Institute of Forming Technology Equipment 7

Introduction of dislocation Institute of Forming Technology & Equipment 7 Understanding of dislocation motion • Pull an entire carpet, the effort is large. • Make a ‘bump’ , move this bump, then the carpet moves forward by a small distance. • The force required to move the bump will be small. • Creating and moving a series of bumps successively, the carpet can be moved forward ‘bit by bit’. Dislocation movement is similar to the way a caterpillar moves

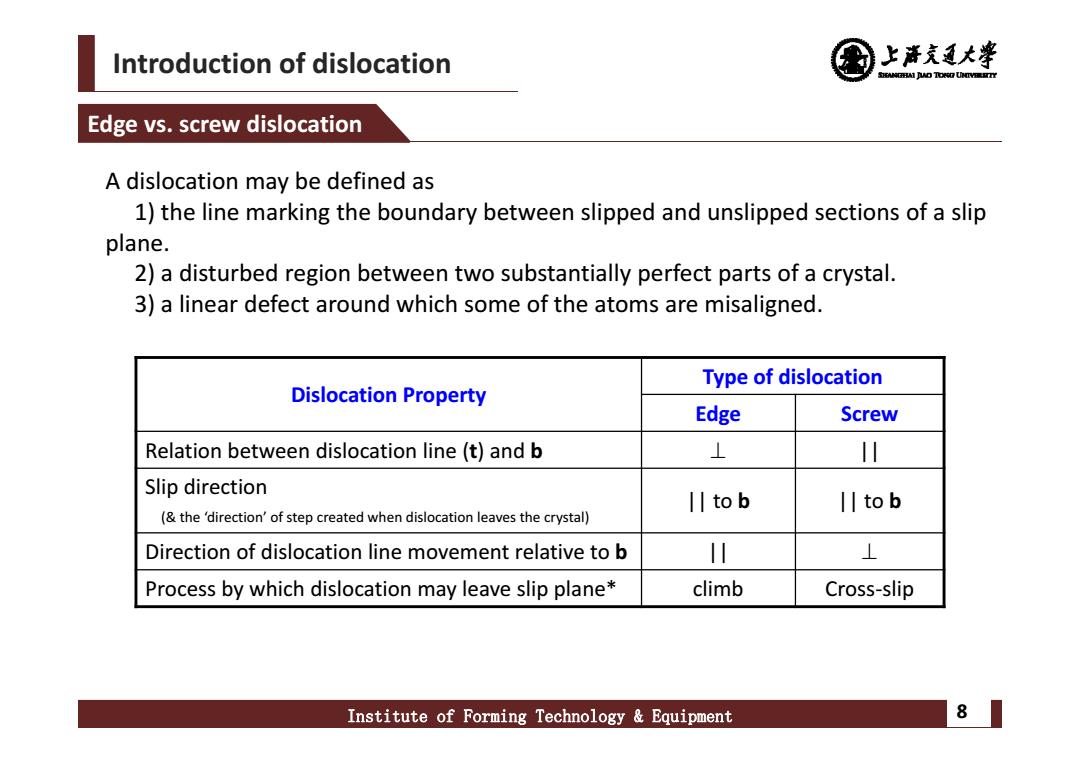

Introduction of dislocation 上清充通大¥ SHEAMGRAI DUD TONO UHTVEREETTY Edge vs.screw dislocation A dislocation may be defined as 1)the line marking the boundary between slipped and unslipped sections of a slip plane. 2)a disturbed region between two substantially perfect parts of a crystal. 3)a linear defect around which some of the atoms are misaligned. Type of dislocation Dislocation Property Edge Screw Relation between dislocation line(t)and b ⊥ 川 Slip direction l川tob II tob (the 'direction'of step created when dislocation leaves the crystal) Direction of dislocation line movement relative to b 1 ⊥ Process by which dislocation may leave slip plane* climb Cross-slip Institute of Forming Technology Equipment 8

Introduction of dislocation Institute of Forming Technology & Equipment 8 Edge vs. screw dislocation Dislocation Property Type of dislocation Edge Screw Relation between dislocation line (t) and b || Slip direction (& the ‘direction’ of step created when dislocation leaves the crystal) || to b || to b Direction of dislocation line movement relative to b || Process by which dislocation may leave slip plane* climb Cross‐slip A dislocation may be defined as 1) the line marking the boundary between slipped and unslipped sections of a slip plane. 2) a disturbed region between two substantially perfect parts of a crystal. 3) a linear defect around which some of the atoms are misaligned

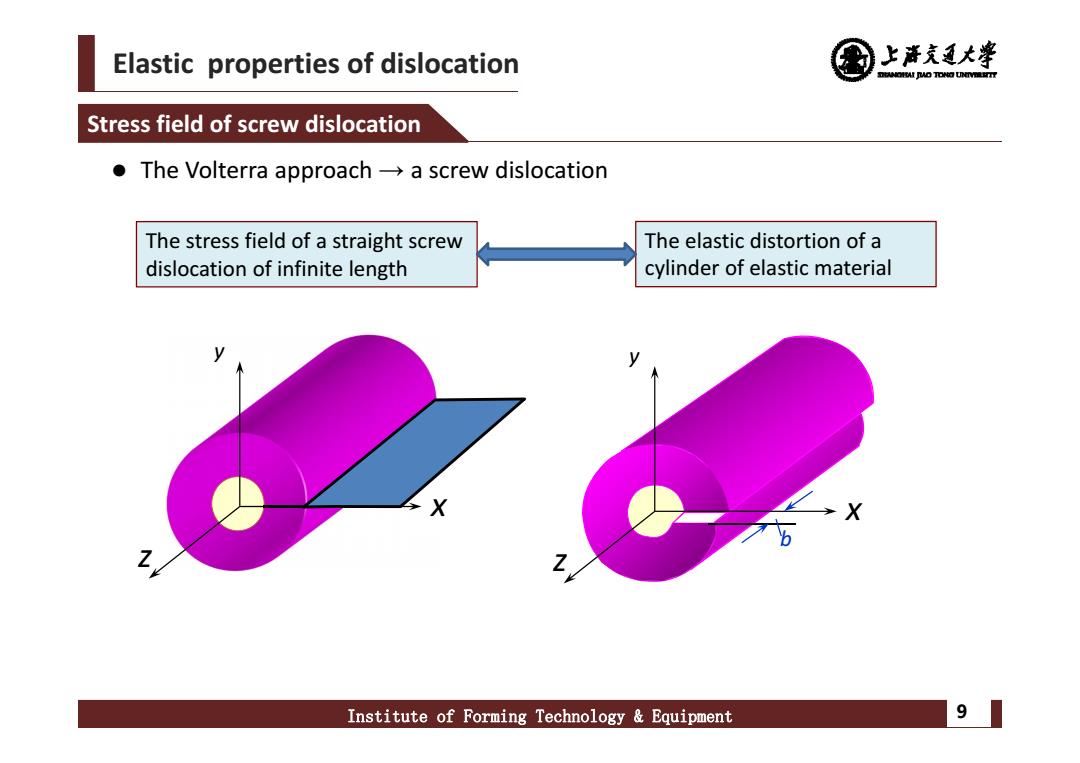

Elastic properties of dislocation 上清充通大学 DREANOIAI AO TONG UNTVEREITT Stress field of screw dislocation ●The Volterra approach→a screw dislocation The stress field of a straight screw The elastic distortion of a dislocation of infinite length cylinder of elastic material Institute of Forming Technology Equipment 9

Elastic properties of dislocation Institute of Forming Technology & Equipment 9 The Volterra approach → a screw dislocation Stress field of screw dislocation z x y z x y b The stress field of a straight screw dislocation of infinite length The elastic distortion of a cylinder of elastic material

Elastic properties of dislocation 上清充通大学 SHEAMGRAI DUD TONO UHTVEREETTY Stress field of screw dislocation The elastic field in cylindrical polar coordinate 0 Note:No strain in radial direction 0 0 T-0 0 b L 2才 Z b z0 Y0:= 2·π·r Gb tg:=t:0=GY6:= 2π Institute of Forming Technology Equipment 10

Elastic properties of dislocation Institute of Forming Technology & Equipment 10 The elastic field in cylindrical polar coordinate Note: No strain in radial direction Stress field of screw dislocation θ L r0 b z x y z z r P L b z z z z z 2 r P r b z 2 r Gb z z G z 2 0 0 0 0 0 0 0 z z

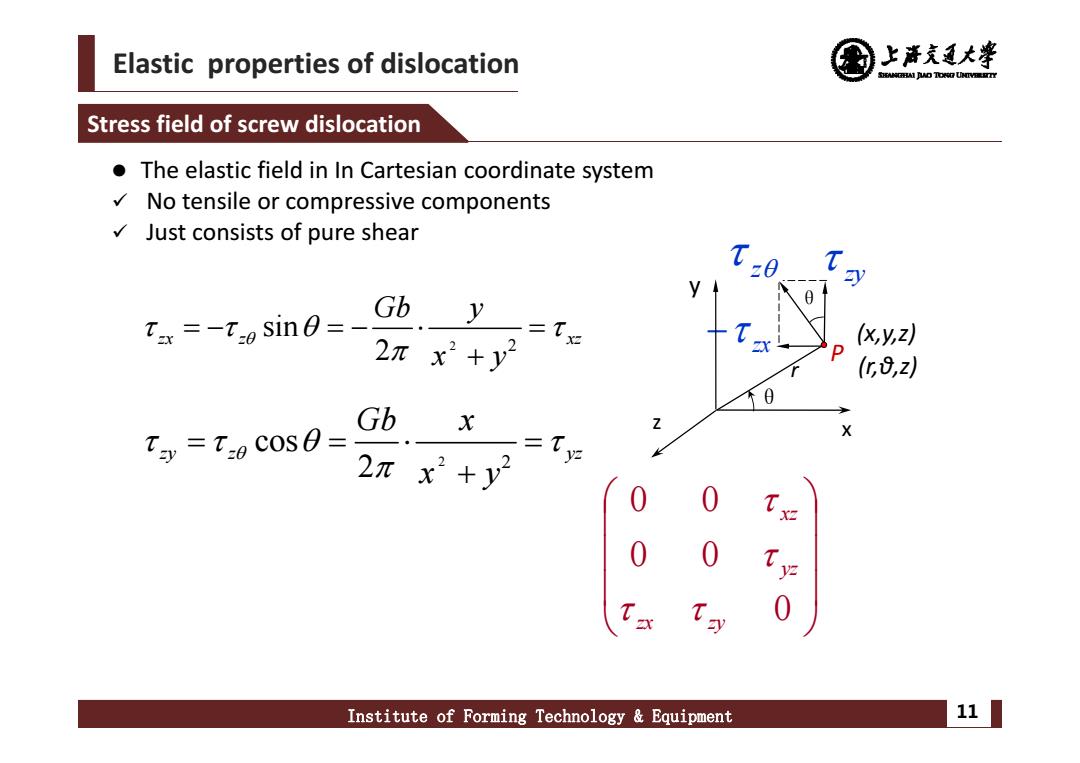

Elastic properties of dislocation 上产克大睾 SHANCBHAI JUAO TONO UNTVEEETTY Stress field of screw dislocation The elastic field inIn Cartesian coordinate system No tensile or compressive components Just consists of pure shear Gb Tax=-t:o sin0=- y 二T 2πx2+y2 (x,y,z) D (G8,z Gb x Ty=T:0 COS0= X 2πx2+y2 Institute of Forming Technology Equipment 11

Elastic properties of dislocation Institute of Forming Technology & Equipment 11 Stress field of screw dislocation 2 2 sin 2 zx z xz Gb y x y 2 2 cos 2 zy z yz Gb x x y 0 0 0 0 0 zx zy yzxz zx θ z y x θ z zy r P (x,y,z) (r,θ,z) The elastic field in In Cartesian coordinate system No tensile or compressive components Just consists of pure shear