第3卷第2期 智能系统学报 Vol.3 Na 2 2008年4月 CAAI Transactions on Intelligent Systems Apr.2008 Fiber optic strain t win-sensor-array for smart structural health monitoring ZHAO Shi-gang',YUAN Li-bo2 (1.National University Science Park,Harbin Engineering University,Harbin 150001,China;2.College of Science,Harbin En- gineering University,Harbin 150001,China) Abstract:A multiplexed white light interferometric fiber optic twimsensor-array was designed to monitor the structural health of large buildings.In this sensing system,based on a Michelson interferometer,an optical path matching technique is used to demodulate each twimsensor.Each twimsensor-array consists of a 2 XN sensing element linked by a 3 dB coupler.When one of the twim sensor is used to measure strain, variations caused by temperature can be compensated for by referencing the other twimsensor.The multi- plexing capacity of the sensing scheme has been analyzed and experimental results with a 2 X3 twinsensor- array are given. Key words :fiber optic sensor;white light interferometer;multiplexing technique;twimsensor-array;tem- perature compensation;Michelson interferometer CLC nember TP311 Document code:A Article ID 1673-4785(2008)02-0177-04 There has been considerable interest recently white light twim sensor-array scheme that meas- in the development of fiber optic sensors based on ures the absolute optical path lengths of each fiber white light interferometry.The use of such a segment end reflective surfaces. technique for distributed strain or temperature 1 Michelson based fiber optic inter- sensing in advanced composite or other structural materials has been discussed in several recent arti- ferometric twin sensor-array clest>51.Fiber optic Michelson sensor arrays are of The sensing principle is shown in Fig.1.The particular interest for such applications because a broadband LED source is directly coupled into the number of reflective-type sensors networked either fiber optic Michelson interferometer by passing in a serial or a parallel topology may be interroga- thorough a 3 dB coupler and lunched into the twim ted by use of a common path-length variable refer-sensor-array.The twimsensor-array consists of ence,thus keeping the system cost down.Several 2 XN fiber segments (N twimsensors)connected schemes have been reported for multiplexing this in series with partial reflectors im between the adja- type of sensors.These include coherence turn- cent fiber segments,configuring a Michelson inter- ing!1,time-division!,spatial division!s,dupli- ferometer based multiplexed fiber optic sensor ar- cate fiber optic switch!3 and 1 XN star coupler!4 ray.The reflected signals of each sensor pair re- multiplexing technique. tune and travel in the same path towards the PIN In this paper,we propose and demonstrate a detector end.One arm of the fiber optic Michelson interferometer as optical path adjusting part has 收稿日期:2007-0918. been used to demodulate the twimsensor-arrays. 基金项目:National Natural Science Foundation of China(60577005); Specialized Research Fund for the Doctoral Program of So that each individual sensor pair is corresponding Higher Education Institute of MOE,China,to Harbin Engineering University. to a unique interference peak because the optical 通讯作者:YUAN Libo.Email:Ibyuan@vp,sna.com. path length is different from each other.For a sen- 1994-2008 China Academic Journal Electronic Publishing House.All rights reserved.htp://www.cnki.net

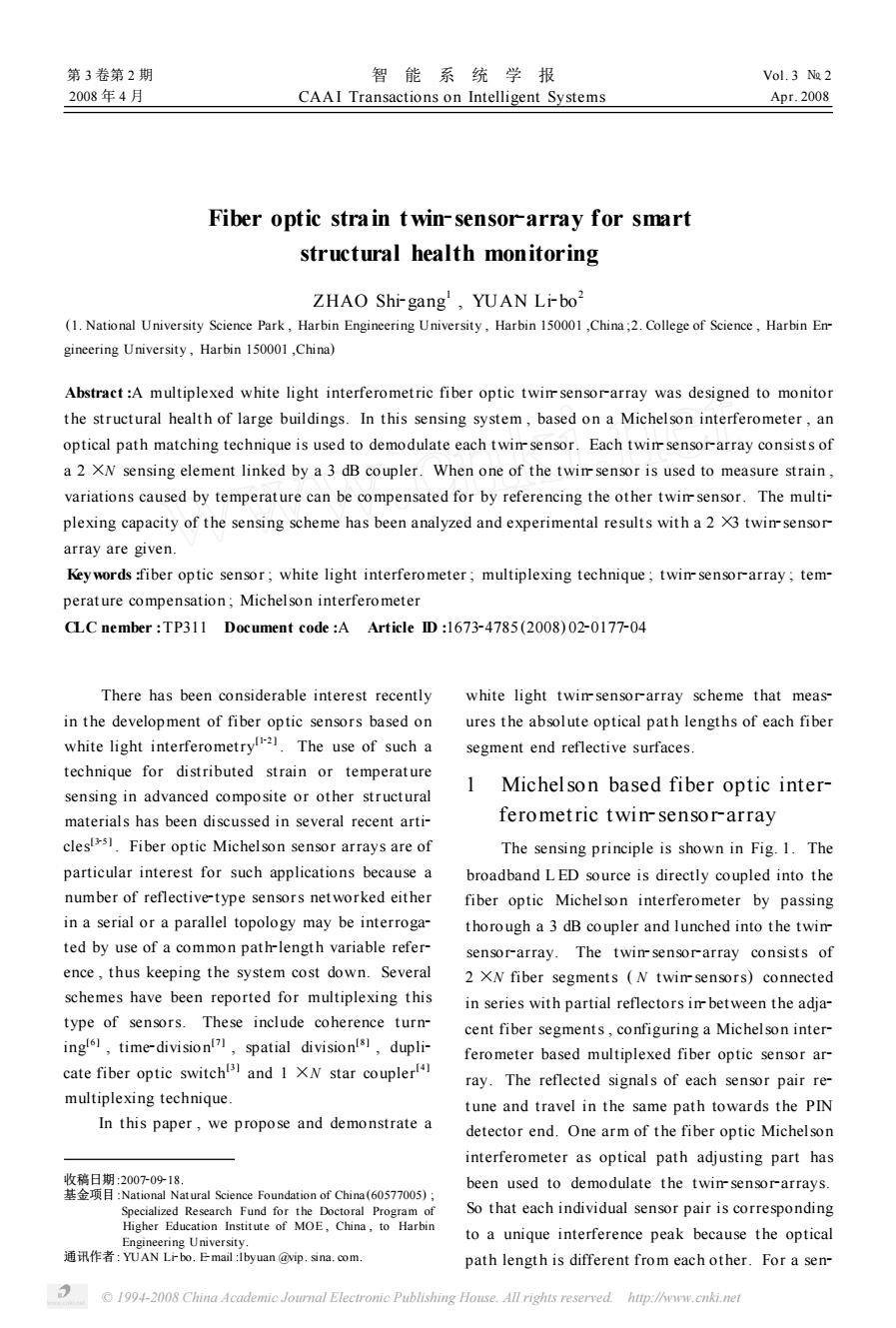

第 3 卷第 2 期 智 能 系 统 学 报 Vol. 3 №. 2 2008 年 4 月 CAA I Transactions on Intelligent Systems Apr. 2008 Fiber optic strain twin2sensor2array for smart structural health monitoring ZHAO Shi2gang 1 , YUAN Li2bo 2 (1. National University Science Park , Harbin Engineering University , Harbin 150001 ,China ;2. College of Science , Harbin En2 gineering University , Harbin 150001 ,China) Abstract :A multiplexed white light interferometric fiber optic twin2sensor2array was designed to monitor t he structural healt h of large buildings. In t his sensing system , based on a Michelson interferometer , an optical path matching technique is used to demodulate each twin2sensor. Each twin2sensor2array consists of a 2 ×N sensing element linked by a 3 dB coupler. When one of t he twin2sensor is used to measure strain , variations caused by temperat ure can be compensated for by referencing the other twin2sensor. The multi2 plexing capacity of t he sensing scheme has been analyzed and experimental results wit h a 2 ×3 twin2sensor2 array are given. Keywords :fiber optic sensor ; white light interferometer ; multiplexing technique ; twin2sensor2array ; tem2 perat ure compensation ; Michelson interferometer CLC nember :TP311 Document code :A Article ID :167324785 (2008) 0220177204 收稿日期 :2007209218. 基金项目 :National Natural Science Foundation of China (60577005) ; Specialized Research Fund for t he Doctoral Program of Higher Education Institute of MOE , China , to Harbin Engineering University. 通讯作者 : YUAN Li2bo. E2mail :lbyuan @vip . sina. com. There has been considerable interest recently in t he development of fiber optic sensors based on white light interferometry [122 ] . The use of such a technique for distributed strain or temperat ure sensing in advanced composite or ot her struct ural materials has been discussed in several recent arti2 cles [325 ] . Fiber optic Michelson sensor arrays are of particular interest for such applications because a number of reflective2type sensors networked eit her in a serial or a parallel topology may be interroga2 ted by use of a common path2lengt h variable refer2 ence , t hus keeping t he system cost down. Several schemes have been reported for multiplexing this type of sensors. These include coherence turn2 ing [6 ] , time2division [7 ] , spatial division [8 ] , dupli2 cate fiber optic switch [3 ] and 1 ×N star coupler [ 4 ] multiplexing technique. In t his paper , we propose and demonstrate a white light twin2sensor2array scheme t hat meas2 ures t he absolute optical pat h lengt hs of each fiber segment end reflective surfaces. 1 Michelson based fiber optic inter2 ferometric twin2sensor2array The sensing principle is shown in Fig. 1. The broadband L ED source is directly coupled into t he fiber optic Michelson interferometer by passing t horough a 3 dB coupler and lunched into t he twin2 sensor2array. The twin2sensor2array consists of 2 ×N fiber segments ( N twin2sensors) connected in series with partial reflectors in2between the adja2 cent fiber segments , configuring a Michelson inter2 ferometer based multiplexed fiber optic sensor ar2 ray. The reflected signals of each sensor pair re2 t une and travel in t he same pat h towards the PIN detector end. One arm of t he fiber optic Michelson interferometer as optical pat h adjusting part has been used to demodulate the twin2sensor2arrays. So that each individual sensor pair is corresponding to a unique interference peak because the optical pat h lengt h is different from each other. For a sen2 © 1994-2008 China Academic Journal Electronic Publishing House. All rights reserved. http://www.cnki.net

·178· 智能系统学报 第3卷 sor pair,if one of the twin sensors is used as a nl。+∑nl=l6+∑l+X (2) strain sensor,the other sensor can be used as a temperature compensated sensor. The shift of the white light interference peak A Xe Scanning mirror corresponds to the variation of the k-th twimsen- sor,i.e. S S2 S LED 3 dB 92923 coupler GRIN △X= ,△(w.△m别 3) PD Lens For the case shown in Fig.2,the sensor array was Fiber attenuator 35889 embedded in the structure.The corresponding twimsensor array was put in a pipe near the sens Fig.I Working principle of the twirarray Michelson ing fiber sensors in order to compensate the varia- fiber optic interferometric strain sensing system tion of the refractive index of the fiber induced by Therefore,the proposed sensing scheme will temperature changes and the elongation of the fiber be useful for temperature compensation of distribu- caused by thermal expansion.The ambient tem- ted strain measurement.An important application perature could be considered the same because the of the sensing system could be deformation sensing twin sensor array has been arranged very close. in smart structures. (T) (T) (T) 2 Sensing principle Fig.2 shows a twimsensor-arrays embedded in (e.T)(e.T) ..(Em.T.) a concrete structure.A number of fiber segments pairs l and l/are connected in serial to form the twim sensor-arrays,which is further connected to a Fig.2 For the case of the twin sensor array arrangement lead in/out fiber of length Lo and Lo.In the sens- in the structure ing system,the length of the two lead in/out fiber In the Fig.2,the sensor array has been em- cables has been chosen as nearly equal,and the bedded in the concrete material,while the refer- same as each fiber segment pairs,i.e. ence array has been put on the pipe in free state L0≈L6, nearby the sensor array. h兰1k, (i,j=1,2,N0 (1) When the strain and its environmental temper- ≠, ature change,the length of the sensing fiber gauge 人4≠ will increase or decrease as a result of both The optical path length of the reference arm Lo can strain and elevated temperature.The optical path be varied through the use of a moving graded index elongation can be expressed as (GRIN)lens or a scanning right angle mirror.One △(nl)=[nAl,(g+△n(gla]+ adjusts the optical path of the reference arm to (nAk(T)+△n(T)h1, 4) match and trace the change of the twimfiber-sensor The compensation sensor array will surely increase gauge length in each sensing pairs.When the opti- as a result of elevated temperature cal-path difference (OPD)between the sensing △(nl0=Al()+△n(TD11.(5) branch and the reference branch falls within the co- Substitute equation (4)and (5)into equation (3) herence length of the light source,a white light and note the condition given in equation (1)1,=1/, fringe pattern is produced.The central fringe, we get which is located in the center of the fringe pattern △Xk= and has the highest amplitude,corresponds to the Pa9+△n91= exact path match of the two optical paths.Thus, nequivalent, 6) we have 1994-2008 China Academic Journal Electronic Publishing House.All rights reserved http://www.cnki.net

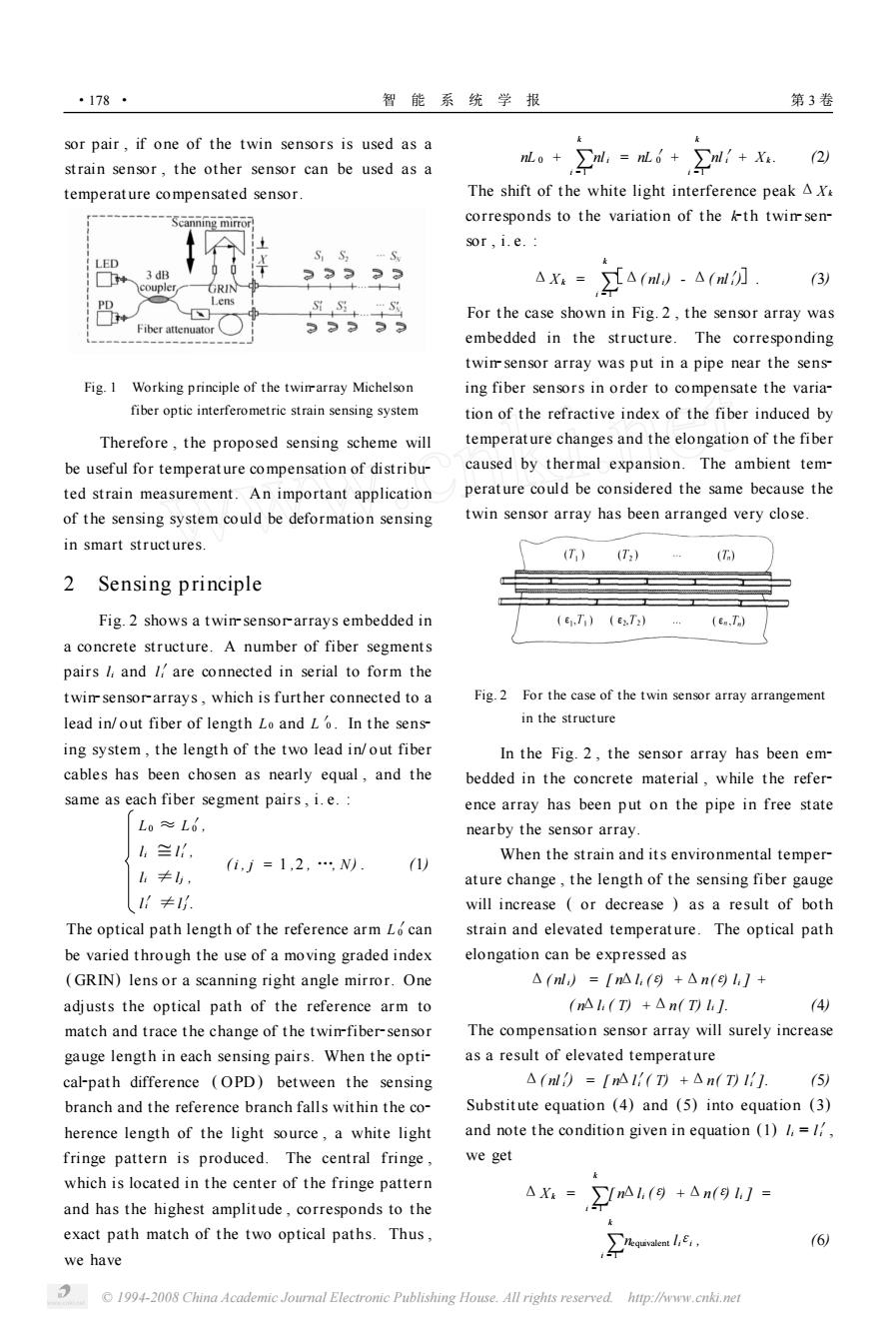

sor pair , if one of t he twin sensors is used as a strain sensor , t he ot her sensor can be used as a temperat ure compensated sensor. Fig. 1 Working principle of the twin2array Michelson fiber optic interferometric strain sensing system Therefore , t he proposed sensing scheme will be usef ul for temperature compensation of distribu2 ted strain measurement. An important application of t he sensing system could be deformation sensing in smart struct ures. 2 Sensing principle Fig. 2 shows a twin2sensor2arrays embedded in a concrete struct ure. A number of fiber segments pairs li and l′i are connected in serial to form the twin2sensor2arrays , which is f urt her connected to a lead in/ out fiber of length L0 and L′0 . In t he sens2 ing system , t he lengt h of the two lead in/ out fiber cables has been chosen as nearly equal , and the same as each fiber segment pairs , i. e. : L0 ≈ L′0 , li µ l′i , li ≠lj , l′i ≠l′j . ( i , j = 1 ,2 , …, N) . (1) The optical pat h length of t he reference arm L′0 can be varied t hrough the use of a moving graded index ( GRIN) lens or a scanning right angle mirror. One adjusts the optical path of the reference arm to match and trace t he change of t he twin2fiber2sensor gauge lengt h in each sensing pairs. When t he opti2 cal2pat h difference ( OPD ) between t he sensing branch and t he reference branch falls wit hin t he co2 herence lengt h of the light source , a white light fringe pattern is produced. The central fringe , which is located in t he center of t he fringe pattern and has t he highest amplit ude , corresponds to the exact pat h match of the two optical pat hs. Thus , we have nL 0 + ∑ k i = 1 nl i = nL′0 + ∑ k i =1 nl′i + Xk . (2) The shift of t he white light interference peak ΔXk corresponds to t he variation of t he k2t h twin2sen2 sor , i. e. : ΔXk = ∑ k i = 1 Δ( nl i) - Δ( nl′i ) . (3) For t he case shown in Fig. 2 , t he sensor array was embedded in the struct ure. The corresponding twin2sensor array was p ut in a pipe near t he sens2 ing fiber sensors in order to compensate t he varia2 tion of t he refractive index of the fiber induced by temperat ure changes and t he elongation of t he fiber caused by thermal expansion. The ambient tem2 perat ure could be considered t he same because t he twin sensor array has been arranged very close. Fig. 2 For the case of the twin sensor array arrangement in the structure In the Fig. 2 , t he sensor array has been em2 bedded in t he concrete material , while t he refer2 ence array has been p ut on t he pipe in free state nearby the sensor array. When the strain and its environmental temper2 ature change , t he lengt h of t he sensing fiber gauge will increase ( or decrease ) as a result of bot h strain and elevated temperat ure. The optical pat h elongation can be expressed as Δ( nl i) = [ nΔli (ε) +Δn(ε) li ] + ( nΔli ( T) +Δn( T) li ]. (4) The compensation sensor array will surely increase as a result of elevated temperat ure Δ( nl′i ) = [ nΔl′i ( T) +Δn( T) l′i ]. (5) Substit ute equation (4) and (5) into equation (3) and note t he condition given in equation (1) li = l′i , we get ΔXk = ∑ k i = 1 [ nΔli (ε) +Δn(ε) li ] = ∑ k i = 1 nequivalent lεi i , (6) · 871 · 智 能 系 统 学 报 第 3 卷 © 1994-2008 China Academic Journal Electronic Publishing House. All rights reserved. http://www.cnki.net

第2期 ZHAO Shi-gang,et al:Fiber optic strain twirr sensor-array for smart structural health monitoring ·179· where =n-2 0.8 ▣Signals intensity represents the equivalent refractive index of the fi- 0.4 ber core.For silica materials at wavelengthA= 1 550 nm,the parameters are n=1.46.=0.25, pu≈0.l2,pn≈0.27iol,and the equivalent re- g Fiber optic sensor number fractive index can be calculated as nequivalent1.19. This means that the peak shift AXe only de- Fig.3 Normalized signal intensity for rth pends on the changes of the fiber optic sensing sensor in the twim sensor-array gauge length l,and the refractive index due to co- axial strain,and it is independent of the optical 4 Experimental results path variations caused by the elevated tempera- A three twim sensor-array was demonstrated ture.Therefore,the changes due to the environ- in our experiments.In the sensing system,the mental temperature fluctuation of the fiber path LED light source power is 30 uW with drive cur- can automatically be compensated. rent 50 mA,and the insertion losses of moving Thus,the distributed strain can be measured GRIN lens part is in the range of 4 dB to 8 dB as by the gap distance from 3 mm to 70 mm (correspond- g=△X:△X4 (8) ing the optical path change within the range 6 mm nequivalent i to 140 mm).And each individual sensor's gauge 3 Analysis of signals intensity length is about 1 000 mm(1 meter single mode op- tical fiber patchcord). The signals intensity is different for the The PIN-detector output when the value of X schemes shown in Fig.1.The signal intensity from is varied from 15 mm to 21.5 mm is shown in sensor pair j that is due to the coherent mixing be- Fig.4.The four major peaks correspond,respec- tween the reflected signals from the two partial re- tively,to the sensor pair being matched of the flectors that define the sensor may be expressed as three twim sensor-array. Pa=gAx[Π7BJ',9 1.2 0.9 where the 2 X2 coupler is assumed to be 3 dB cou- 0.6 0.3 pler and the insertion losses are neglected.B re- 0 presents the excess loss associated with sensor j A/indino -0.3 -0.6 because connection loss between the sensing seg- -0.9 ments.T,and R,are respectively the transmission -13 0.15 0.651.151.652.14x10 and reflection coefficient of the fth partial reflec- Scanning displacement/gm tor.T,is in general smaller than 1-R,because of the loss factor B.nX)is the loss associated with Fig.4 Three twimfibersensor array experimental the moving GRIN lenses systems and is a function scanning peak signals of Xj. Theoretical simulations were conducted for In order to show the compensation efficiency typical parameters:B =0.9(j=1,2...N+1), of the sensor system,the experiments were per- R,=1 %T=0.89.The average attenuation of formed under the two different circumstances of the moving GRIN lens part is taken as 6 dB,i.e. temperature conditions.The test coupon is depic- X)=1/4.The power coupled into the input fi- ted in Fig.5.The load was supplied from a load ber is Po.The normalized signal intensity for each cell to the test coupon and introduced a uniform sensor in the 10 sensors array is shown in Fig.3. stress field o.Then the corresponding strain will 1994-2008 China Academie Journal Electronic Publishing House.All rights reserved.hup://www.cnki.net

where nequivalent = n - 1 2 n 3 [ (1 - μ) p12 - μp11 ] (7) represents the equivalent refractive index of t he fi2 ber core. For silica materials at wavelengt h λ= 1 550 nm , t he parameters are n = 1. 46 , μ= 0. 25 , p11≈0. 12 , p12 ≈0. 27 [10 ] , and t he equivalent re2 fractive index can be calculated as nequivalent≈1. 19 . This means t hat t he peak shift ΔXk only de2 pends on t he changes of t he fiber optic sensing gauge lengt h li and t he refractive index due to co2 axial strain , and it is independent of t he optical path variations caused by t he elevated tempera2 t ure. Therefore , t he changes due to the environ2 mental temperat ure fluctuation of the fiber pat h can automatically be compensated. Thus , the distributed strain can be measured by εi = ΔXi - ΔXi- 1 nequivalent li . (8) 3 Analysis of signals intensity The signals intensity is different for the schemes shown in Fig. 1. The signal intensity from sensor pair j t hat is due to t he coherent mixing be2 tween the reflected signals from the two partial re2 flectors that define t he sensor may be expressed as PD1 ( j) = 1 8 P0η( Xj) Rj+1 ∏ j i =1 ( Tβi i) 2 , (9) where t he 2 ×2 coupler is assumed to be 3 dB cou2 pler and t he insertion losses are neglected. βj re2 presents t he excess loss associated with sensor j because connection loss between t he sensing seg2 ments. Tj and Rj are respectively t he transmission and reflection coefficient of the j2th partial reflec2 tor. Tj is in general smaller t han 1 - Rj because of t he loss factorβj . η( Xj) is the loss associated wit h t he moving GRIN lenses systems and is a f unction of Xj . Theoretical simulations were conducted for typical parameters:βj = 0. 9 ( j = 1 , 2 , …, N + 1) , Rj = 1 % , Tj = 0. 89. The average attenuation of t he moving GRIN lens part is taken as 6 dB , i. e. η( Xj) = 1/ 4. The power coupled into t he inp ut fi2 ber is P0 . The normalized signal intensity for each sensor in t he 10 sensors array is shown in Fig. 3. Fig. 3 Normalized signal intensity for i2th sensor in the twin2sensor2array. 4 Experimental results A t hree twin2sensor2array was demonstrated in our experiments. In t he sensing system , t he L ED light source power is 30 μW with drive cur2 rent 50 mA , and t he insertion losses of moving GRIN lens part is in t he range of 4 dB to 8 dB as t he gap distance from 3 mm to 70 mm (correspond2 ing t he optical pat h change wit hin the range 6 mm to 140 mm) . And each individual sensor’s gauge lengt h is about 1 000 mm (1 meter single mode op2 tical fiber patchcord) . The PIN2detector outp ut when t he value of X is varied from 15 mm to 21. 5 mm is shown in Fig. 4. The four major peaks correspond , respec2 tively , to the sensor pair being matched of t he t hree twin2sensor2array. Fig. 4 Three twin2fiber2sensor array experimental scanning peak signals In order to show t he compensation efficiency of t he sensor system , t he experiments were per2 formed under t he two different circumstances of temperat ure conditions. The test coupon is depic2 ted in Fig. 5. The load was supplied from a load cell to the test coupon and introduced a uniform stress field σ. Then t he corresponding strain will 第 2 期 ZHAO Shi2gang ,et al :Fiber optic strain twin2sensor2array for smart structural health monitoring · 971 · © 1994-2008 China Academic Journal Electronic Publishing House. All rights reserved. http://www.cnki.net

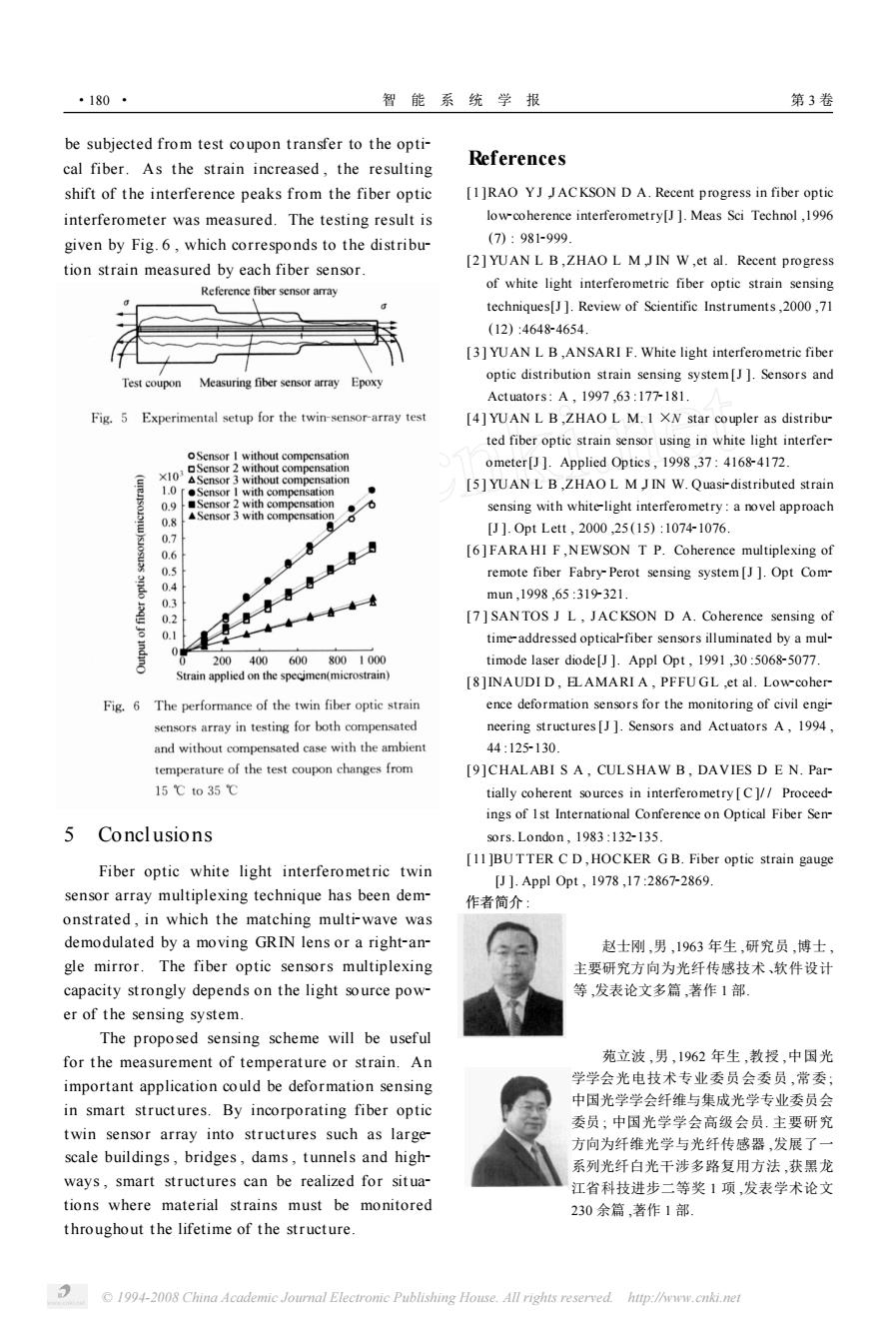

·180· 智能系统学报 第3卷 be subjected from test coupon transfer to the opti- cal fiber.As the strain increased,the resulting References shift of the interference peaks from the fiber optic [1]RAO YJ JACKSON D A.Recent progress in fiber optic interferometer was measured.The testing result is low-coherence interferometry[J].Meas Sci Technol,1996 given by Fig.6,which corresponds to the distribu- (7):981-999. [2]YUAN L B,ZHAO L M JIN W,et al.Recent progress tion strain measured by each fiber sensor Reference fiber sensor array of white light interferometric fiber optic strain sensing 6 techniques[J].Review of Scientific Instruments,2000,71 (12):46484654. [3]YUAN L B,ANSARI F.White light interferometric fiber Test coupon Measuring fiber sensor array Epoxy optic distribution strain sensing system[J].Sensors and Actuators:A,1997,63:177181 Fig.5 Experimental setup for the twin-sensor-array test [4]YUAN L B,ZHAO L M.I XN star coupler as distribu ted fiber optic strain sensor using in white light interfer oSensor I without compensation X103 Sensor without compensation ometer[J ]Applied Optics,1998,37:4168-4172 ASensor 3 without compensation 1.0[eSensor I with compensation [5]YUAN L B,ZHAO L M J IN W.Quasi-distributed strain 0.9Sensor 2 with compensation ● sensing with white-light interferometry:a novel approach 08 ASensor 3 with compensation [J].Opt Lett,2000,25(15):10741076. 0.7 0.6 6]FARA HI F,NEWSON T P.Coherence multiplexing of 0.5 remote fiber Fabry-Perot sensing system[J].Opt Com- 0.4 mun,1998,65:319321. 0.3 0.2 [7]SANTOS J L,JACKSON D A.Coherence sensing of 01 ★ time-addressed optical-fiber sensors illuminated by a mul- 2004006008001000 timode laser diode [J ]Appl Opt,1991,30:5068-5077 Strain applied on the specimen(microstrain) [8]INAUDI D,ELAMARI A.PFFUGLet al.Low-coher- Fig.6 The performance of the twin fiber optic strain ence deformation sensors for the monitoring of civil engi- sensors array in testing for both compensated neering structures [J ]Sensors and Actuators A,1994, and without compensated case with the ambient 44:125130. temperature of the test coupon changes from (9]CHALABI S A,CULSHAW B,DAVIES D E N.Par- 15℃to35℃ tially coherent sources in interferometry C]//Proceed- ings of Ist International Conference on Optical Fiber Sen- 5 Conclusions s0rs.London,1983:132-135. [11]BUTTER C D,HOCKER G B.Fiber optic strain gauge Fiber optic white light interferometric twin U].Appl0pt,1978,17:2867-2869. sensor array multiplexing technique has been dem- 作者简介: onstrated,in which the matching multi-wave was demodulated by a moving GRIN lens or a right-an- 赵士刚,男,1963年生研究员,博士 gle mirror.The fiber optic sensors multiplexing 主要研究方向为光纤传感技术、软件设计 capacity strongly depends on the light source pow- 等,发表论文多篇,著作1部 er of the sensing system. The proposed sensing scheme will be useful for the measurement of temperature or strain.An 苑立波,男,1962年生,教授,中国光 important application could be deformation sensing 学学会光电技术专业委员会委员,常委; 中国光学学会纤维与集成光学专业委员会 in smart structures.By incorporating fiber optic 委员;中因光学学会高级会员.主要研究 twin sensor array into structures such as large- 方向为纤维光学与光纤传感器,发展了一 scale buildings,bridges,dams,tunnels and high- 系列光纤白光干涉多路复用方法,获黑龙 ways,smart structures can be realized for situa- 江省科技进步二等奖1项,发表学术论文 tions where material strains must be monitored 230余篇,著作1部 throughout the lifetime of the structure. 1994-2008 China Academic Journal Electronic Publishing House.All rights reserved http://www.cnki.net

be subjected from test coupon transfer to t he opti2 cal fiber. As t he strain increased , the resulting shift of t he interference peaks from t he fiber optic interferometer was measured. The testing result is given by Fig. 6 , which corresponds to the distribu2 tion strain measured by each fiber sensor. 5 Conclusions Fiber optic white light interferometric twin sensor array multiplexing technique has been dem2 onstrated , in which t he matching multi2wave was demodulated by a moving GRIN lens or a right2an2 gle mirror. The fiber optic sensors multiplexing capacity strongly depends on t he light source pow2 er of t he sensing system. The propo sed sensing scheme will be usef ul for t he measurement of temperat ure or strain. An important application could be deformation sensing in smart struct ures. By incorporating fiber optic twin sensor array into structures such as large2 scale buildings , bridges , dams , t unnels and high2 ways , smart struct ures can be realized for sit ua2 tions where material strains must be monitored t hroughout t he lifetime of t he structure. References [1 ]RAO Y J ,J ACKSON D A. Recent progress in fiber optic low2coherence interferometry[J ]. Meas Sci Technol ,1996 (7) : 9812999. [2 ] YUAN L B ,ZHAO L M ,J IN W ,et al. Recent progress of white light interferometric fiber optic strain sensing techniques[J ]. Review of Scientific Instruments ,2000 ,71 (12) :464824654. [ 3 ] YUAN L B ,ANSARI F. White light interferometric fiber optic distribution strain sensing system[J ]. Sensors and Actuators: A , 1997 ,63 :1772181. [4 ] YUAN L B ,ZHAO L M. 1 ×N star coupler as distribu2 ted fiber optic strain sensor using in white light interfer2 ometer[J ]. Applied Optics , 1998 ,37 : 416824172. [5 ] YUAN L B ,ZHAO L M ,J IN W. Quasi2distributed strain sensing with white2light interferometry : a novel approach [J ]. Opt Lett , 2000 ,25 (15) :107421076. [6 ] FARA HI F ,N EWSON T P. Coherence multiplexing of remote fiber Fabry2Perot sensing system [J ]. Opt Com2 mun ,1998 ,65 :3192321. [ 7 ] SAN TOS J L , J ACKSON D A. Coherence sensing of time2addressed optical2fiber sensors illuminated by a mul2 timode laser diode[J ]. Appl Opt , 1991 ,30 :506825077. [8 ]INAUDI D , ELAMARI A , PFFU GL ,et al. Low2coher2 ence deformation sensors for the monitoring of civil engi2 neering structures[J ]. Sensors and Actuators A , 1994 , 44 :1252130. [9 ]CHALABI S A , CULSHAW B , DAVIES D E N. Par2 tially coherent sources in interferometry [ C ]/ / Proceed2 ings of 1st International Conference on Optical Fiber Sen2 sors. London , 1983 :1322135. [11 ]BU TTER C D , HOCKER G B. Fiber optic strain gauge [J ]. Appl Opt , 1978 ,17 :286722869. 作者简介 : 赵士刚 ,男 ,1963 年生 ,研究员 ,博士 , 主要研究方向为光纤传感技术、软件设计 等 ,发表论文多篇 ,著作 1 部. 苑立波 ,男 ,1962 年生 ,教授 ,中国光 学学会光电技术专业委员会委员 ,常委 ; 中国光学学会纤维与集成光学专业委员会 委员 ; 中国光学学会高级会员. 主要研究 方向为纤维光学与光纤传感器 ,发展了一 系列光纤白光干涉多路复用方法 ,获黑龙 江省科技进步二等奖 1 项 ,发表学术论文 230 余篇 ,著作 1 部. · 081 · 智 能 系 统 学 报 第 3 卷 © 1994-2008 China Academic Journal Electronic Publishing House. All rights reserved. http://www.cnki.net