Chapter 8 Starting system Section I Engine starting and method 1.Internal Combustion Engine Start Gasoline engine is at a temperature of 0-20 C,the minimum starting speed of 30-40r/min.In order to be at lower temperature of the engine that can be reliably started,it needs the starting speed ofnot less than 50-70r/min. Requirement for diesel engine starting speed is high,reaching 150-300r/min, otherwise poor atomization of diesel,gas mixture of poor quality,and to be difficulty in starting the engine.In addition,diesel engine compression ratio is larger than gasoline engine,and starting torque is also large,so diesel engine requires big starting power. 2.The Starting Method of Internal Combustion Engine (1)Human start. (2)Electric start. (3)Diesel engine started by gasoline engine. 机被与电子工程学原 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 8 Starting system 1. Internal Combustion Engine Start Gasoline engine is at a temperature of 0-20 ℃, the minimum starting speed of 30-40r/min. In order to be at lower temperature of the engine that can be reliably started, it needs the starting speed of not less than 50-70r/min. Requirement for diesel engine starting speed is high, reaching 150-300r/min, otherwise poor atomization of diesel, gas mixture of poor quality, and to be difficulty in starting the engine. In addition, diesel engine compression ratio is larger than gasoline engine, and starting torque is also large, so diesel engine requires big starting power. 2. The Starting Method of Internal Combustion Engine (1) Human start. (2) Electric start. (3) Diesel engine started by gasoline engine. Section 1 Engine starting and method

Chapter 8 Starting system Section 2 Electric start system The meshing mechanism of electric starter There are two commonly used types: (1)lever type (2)electromagnetic type .5-3m Figure 8.1 Electromagnetic engaging mechanism 1.starting switch 2.fixed contact 3.dynamic contact bridge 4.retaining coil 5.suction pull coil 6.iron core 7.tie rod 8.transmission fork 9.one-way clutch 10.drive gear 11.armature 12.wire brush 13. magnetic pole 械电子工程学 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 8 Starting system The meshing mechanism of electric starter There are two commonly used types: (1) lever type (2) electromagnetic type Figure 8.1 Electromagnetic engaging mechanism 1. starting switch 2. fixed contact 3. dynamic contact bridge 4. retaining coil 5. suction pull coil 6. iron core 7. tie rod 8. transmission fork 9. one-way clutch 10. drive gear 11. armature 12. wire brush 13. magnetic pole Section 2 Electric start system

Chapter8 Starting system Section 3 Starting auxiliary device Usually two ways to improve startup performance:the one is to lower engine starting resistance;the second is to improve the fire conditions. 1.Start Decompressing Mechanism Because diesel engine compression ratio and start-resistance is large,cylinder compressure can be reduced by opening the valve.Decompressing mechanism can complete this method. 2.Electric Heating Plug In the swirl chamber or pre-combustion chamber of diesel engine,the combustion chamber is equipped with electric heating plugs,which warm up the air in the combustion chamber at the start. 3.Intake Preheater In the medium power diesel engines,the intake preheater is used as a cold start preheating device. 4.Starting Fluid Spurting Device According to the need,in some diesel engine can use starting fluid spurting device 机被寿电子工程学模 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 8 Starting system Usually two ways to improve startup performance: the one is to lower engine starting resistance;the second is to improve the fire conditions. 1. Start Decompressing Mechanism Because diesel engine compression ratio and start-resistance is large, cylinder compressure can be reduced by opening the valve. Decompressing mechanism can complete this method. 2. Electric Heating Plug In the swirl chamber or pre-combustion chamber of diesel engine, the combustion chamber is equipped with electric heating plugs, which warm up the air in the combustion chamber at the start. 3. Intake Preheater In the medium power diesel engines, the intake preheater is used as a cold start preheating device. 4. Starting Fluid Spurting Device According to the need, in some diesel engine can use starting fluid spurting device. Section 3 Starting auxiliary device

Chapter 9 Gasoline ignition system Section 1 Requirements and classification The engine ignition has three ways of hot fire ignition,compression ignition and electric spark ignition.Diesel engines use compression ignition,and gasoline engines generally use electric spark ignition. 1.The Requirements of The Ignition System (1)It can produce enough high-voltage 15-20kV to puncture spark plug gap. (2)Spark plug should have enough energy 50-80MJ. (3)Ignition timing should be adapted to the work of the engine. 2.Classification of The Ignition System (1)Conventional ignition system. (2)Semiconductor ignition system. (3)Computer controlled ignition system. (4)Magneto ignition system. 机械电子工程学度 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 9 Gasoline ignition system The engine ignition has three ways of hot fire ignition, compression ignition and electric spark ignition. Diesel engines use compression ignition, and gasoline engines generally use electric spark ignition. 1. The Requirements of The Ignition System (1) It can produce enough high-voltage 15-20kVto puncture spark plug gap. (2) Spark plug should have enough energy 50-80MJ. (3) Ignition timing should be adapted to the work of the engine. 2. Classification of The Ignition System (1) Conventional ignition system. (2) Semiconductor ignition system. (3) Computer controlled ignition system. (4) Magneto ignition system. Section 1 Requirements and classification

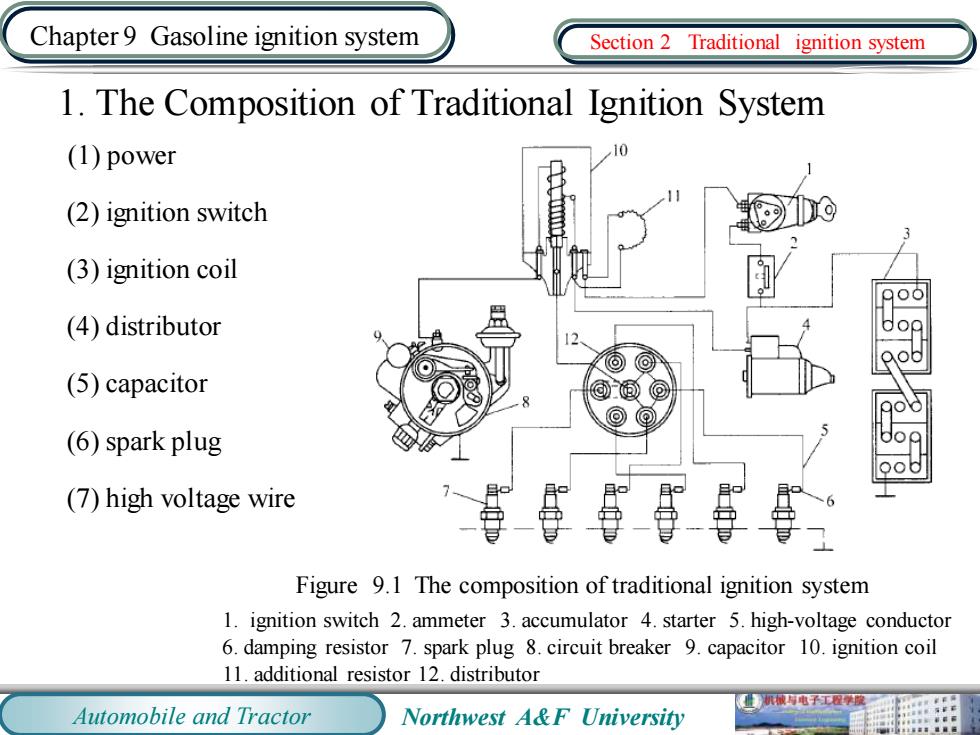

Chapter 9 Gasoline ignition system Section 2 Traditional ignition system 1.The Composition of Traditional Ignition System (1)power 10 (2)ignition switch (3)ignition coil (4)distributor @ (5)capacitor (6)spark plug ood (7)high voltage wire 莓昏香草 Figure 9.1 The composition of traditional ignition system 1.ignition switch 2.ammeter 3.accumulator 4.starter 5.high-voltage conductor 6.damping resistor 7.spark plug 8.circuit breaker 9.capacitor 10.ignition coil 11.additional resistor 12.distributor 业机械与电子工程模 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 9 Gasoline ignition system 1. The Composition of Traditional Ignition System (1) power (2) ignition switch (3) ignition coil (4) distributor (5) capacitor (6) spark plug (7) high voltage wire Figure 9.1 The composition of traditional ignition system 1. ignition switch 2. ammeter 3. accumulator 4. starter 5. high-voltage conductor 6. damping resistor 7. spark plug 8. circuit breaker 9. capacitor 10. ignition coil 11. additional resistor 12. distributor Section 2 Traditional ignition system

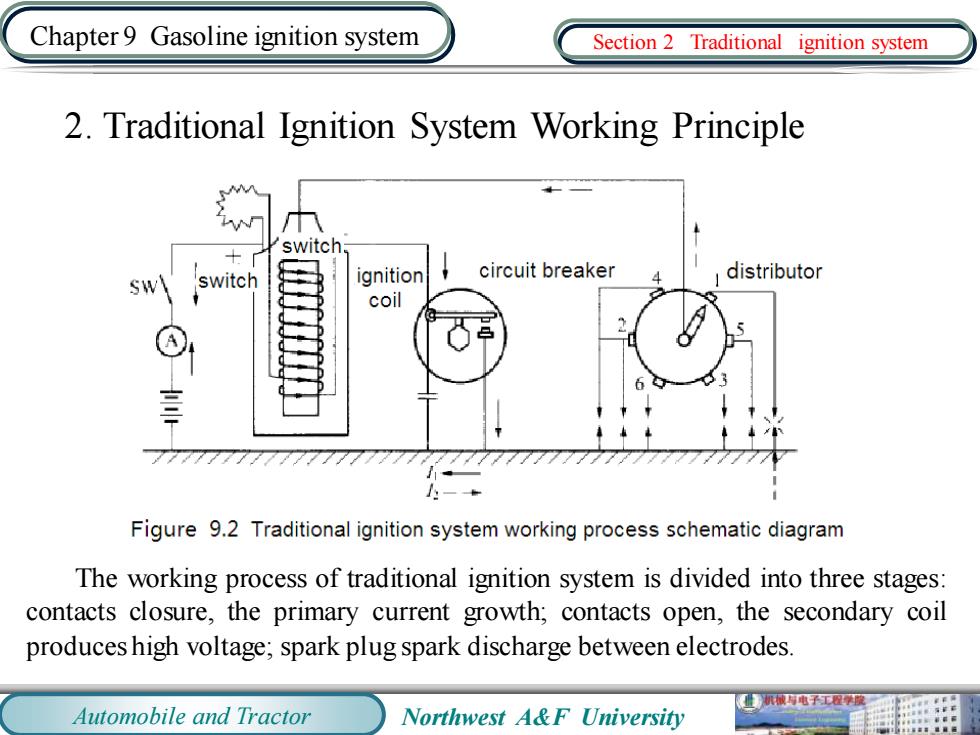

Chapter9 Gasoline ignition system Section 2 Traditional ignition system 2.Traditional Ignition System Working Principle switch: switch ignition circuit breaker distributor coil Figure 9.2 Traditional ignition system working process schematic diagram The working process of traditional ignition system is divided into three stages: contacts closure,the primary current growth;contacts open,the secondary coil produces high voltage;spark plug spark discharge between electrodes. 械电子工程学 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 9 Gasoline ignition system 2. Traditional Ignition System Working Principle The working process of traditional ignition system is divided into three stages: contacts closure, the primary current growth; contacts open, the secondary coil produces high voltage; spark plug spark discharge between electrodes. Section 2 Traditional ignition system

Chapter 9 Gasoline ignition system Section 3 Computer ignition control system 1.Characteristics and Types 1.1 Characteristics Conventional ignition system and electronic ignition there are still some less than satisfactory,especially for the control of the ignition time. The greatest success of computer control is to achieve the automatic control of the ignition advance angle.Namely,according to working conditions of the engine, the ignition advance angle can be timely controlled to obtain the best combustion mixture. In the computer ignition control system,ignition control,includes the ignition advance angle control,conduction time control and knock control.It has three characteristics: (1)In a variety of working conditions,it can obtain optimal ignition advance angle (2)In the range of all the work,the ignition coil on-time control makes the ignition coil stored energy that remains constant,which increases the reliability of ignition 机被寿电子工程原 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 9 Gasoline ignition system 1. Characteristics and Types 1.1 Characteristics Conventional ignition system and electronic ignition there are still some less than satisfactory, especially for the control of the ignition time. The greatest success of computer control is to achieve the automatic control of the ignition advance angle. Namely, according to working conditions of the engine, the ignition advance angle can be timely controlled to obtain the best combustion mixture. In the computer ignition control system, ignition control, includes the ignition advance angle control, conduction time control and knock control. It has three characteristics: (1)In a variety of working conditions, it can obtain optimal ignition advance angle; (2)In the range of all the work, the ignition coil on-time control makes the ignition coil stored energy that remains constant, which increases the reliability of ignition; Section 3 Computer ignition control system

Chapter9 Gasoline ignition system Section 3 Computer ignition control system (3)Using closed-loop control makes the ignition advance angle control of each cylinder that just does not occur in the detonation of the critical state,resulting in higher combustion efficiency,and helps to improve a variety of engine performance. 1.2 Types 1.2.1 Divided by high voltage distribution in different ways (1)machinery high voltage distribution High-voltage is produced by the traditional distributor distribution ignition coil. (2)Electronic high voltage distribution High voltage distributed by the electronic control,this fully electronic microcomputer ignition control system is divided into two types.The one is not equipped with distributor,but the ignition coil and spark plug is connected with high voltage wire;the other has no high-voltage wire,above each spark plug is directly connected with an ignition coil. 1.2.2 Divided by the ignition in different ways (1)the ignition by group at the same time The spark plugs of each cylinder is generally grouped in pairs.Each time the 械电子工程学膜 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 9 Gasoline ignition system (3)Using closed-loop control makes the ignition advance angle control of each cylinder that just does not occur in the detonation of the critical state, resulting in higher combustion efficiency,and helpsto improve a variety of engine performance. 1.2 Types 1.2.1 Divided by high voltage distribution in different ways (1) machinery high voltage distribution High-voltage is produced by the traditional distributor distribution ignition coil. (2) Electronic high voltage distribution High voltage distributed by the electronic control, this fully electronic microcomputer ignition control system is divided into two types. The one is not equipped with distributor, but the ignition coil and spark plug is connected with high voltage wire; the other has no high-voltage wire , above each spark plug is directly connected with an ignition coil. 1.2.2 Divided by the ignition in different ways (1) the ignition by group at the same time The spark plugs of each cylinder is generally grouped in pairs. Each time the Section 3 Computer ignition control system

Chapter 9 Gasoline ignition system Section 3 Computer ignition control system ignition is in the same group of two-cylinder spark plugs at the same time,and one of the cylinders is effective in pairs,while for the exhaust stroke of another cylinder, the ignition is not valid. (2)direct ignition Spark plugs of per cylinder are equipped with a separate ignition coil,and ignition coil is usually installed directly above the spark plug,so high-voltage wires can be avoided. 1.2.3 Divided by feedback control is there or not (1)open-loopcontrol Microcomputer ignition control has no knock sensor,and the controller is to control the ignition advance angle with the sensor signals that reflect the conditions and states of the engine. (2)closed-loopcontrol Microcomputer ignition control is equipped with knock sensor.The knock sensor can feedback the deflagration case of the engine,then make amendments to the ignition advance angle control.The ignition advance angle is closer to the detonation area,which is effective in playing the engine's power.At present,most of the microcomputer ignition control use closed loop control 机被灯电子工程学膜 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 9 Gasoline ignition system ignition is in the same group of two-cylinder spark plugs at the same time, and one of the cylinders is effective in pairs,while for the exhaust stroke of another cylinder, the ignition is not valid. (2) direct ignition Spark plugs of per cylinder are equipped with a separate ignition coil, and ignition coil is usually installed directly above the spark plug, so high-voltage wires can be avoided. 1.2.3 Divided by feedback control is there or not (1) open-loop control Microcomputer ignition control has no knock sensor, and the controller is to control the ignition advance angle with the sensor signals that reflect the conditions and states of the engine. (2) closed-loop control Microcomputer ignition control is equipped with knock sensor. The knock sensor can feedback the deflagration case of the engine, then make amendments to the ignition advance angle control. The ignition advance angle is closer to the detonation area, which is effective in playing the engine‘s power.At present, most of the microcomputerignition control use closed loop control. Section 3 Computer ignition control system

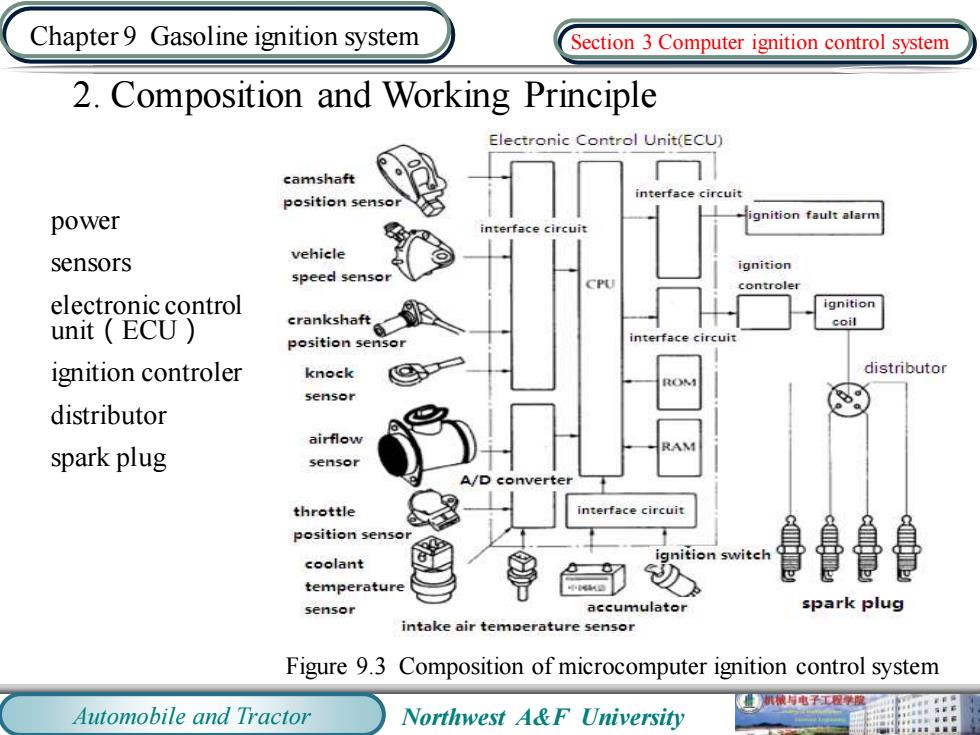

Chapter9 Gasoline ignition system Section 3 Computer ignition control system 2.Composition and Working Principle Electronic Control Unit(ECU) camshaft interface circuit position sensor power ignition fault alarm interface circuit vehicle sensors ignition speed sensor controler electronic control ignition unit (ECU) crankshaft coil position senso nterface circuit ignition controler knock distributor sensor distributor airflow spark plug sensor throttle nterface circuit position sen coolant temperatur sensor accumulator spark plug intake air temperature sensor Figure 9.3 Composition of microcomputer ignition control system 械电子工程学膜 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 9 Gasoline ignition system 2. Composition and Working Principle Figure 9.3 Composition of microcomputer ignition control system power sensors electronic control unit(ECU) ignition controler distributor spark plug Section 3 Computer ignition control system