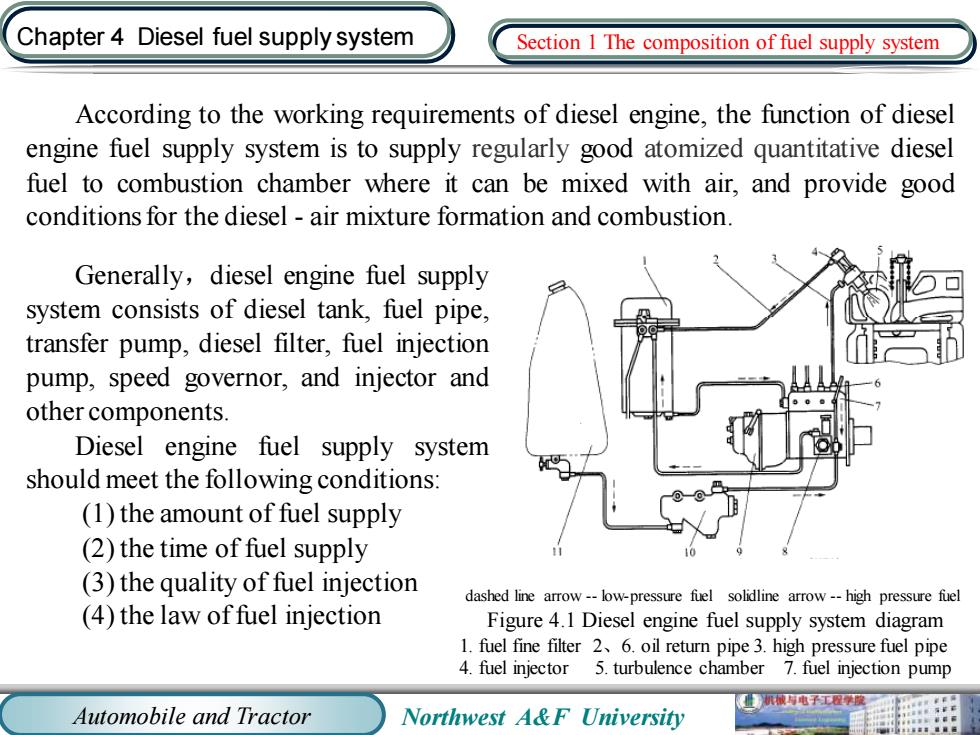

Chapter 4 Diesel fuel supply system Section I The composition of fuel supply system According to the working requirements of diesel engine,the function of diesel engine fuel supply system is to supply regularly good atomized quantitative diesel fuel to combustion chamber where it can be mixed with air,and provide good conditions for the diesel-air mixture formation and combustion. Generally,diesel engine fuel supply system consists of diesel tank,fuel pipe, transfer pump,diesel filter,fuel injection pump,speed governor,and injector and other components. Diesel engine fuel supply system should meet the following conditions: (1)the amount of fuel supply (2)the time of fuel supply (3)the quality of fuel injection dashed line arrow--low-pressure fuel solidline arrow--high pressure fuel (4)the law of fuel injection Figure 4.1 Diesel engine fuel supply system diagram 1.fuel fine filter 2.6.oil return pipe 3.high pressure fuel pipe 4.fuel injector 5.turbulence chamber 7.fuel injection pump Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 4 Diesel fuel supply system Generally,diesel engine fuel supply system consists of diesel tank, fuel pipe, transfer pump, diesel filter, fuel injection pump, speed governor, and injector and other components. Diesel engine fuel supply system should meet the following conditions: (1) the amount of fuel supply (2) the time of fuel supply (3) the quality of fuel injection (4) the law of fuel injection Section 1 The composition of fuel supply system According to the working requirements of diesel engine, the function of diesel engine fuel supply system is to supply regularly good atomized quantitative diesel fuel to combustion chamber where it can be mixed with air, and provide good conditionsfor the diesel - air mixture formation and combustion. dashed line arrow -- low-pressure fuel solidline arrow -- high pressure fuel Figure 4.1 Diesel engine fuel supply system diagram 1. fuel fine filter 2、6. oil return pipe 3. high pressure fuel pipe 4. fuel injector 5. turbulence chamber 7. fuel injection pump

Chapter 4 Diesel fuel supply system Section 2 Mixture formation and combustion chamber 1.Formation and Combustion of Combustible Mixture According to the variation feature of the cylinder temperature and pressure,the formation and combustion of diesel engine mixture can be divided into four periods according to the crank angle: , (1)Fire delay period:This period is from the fuel injected into the cylinder the starting point (A)to beginning fire point(B)(Fire delay). (2)Rapid combustion period:This period starting from the beginning fire point (B)to rapidly burning until the maximum pressure point(C). -cylinder pressure change (3)Slow combustion period:This period is without fuel supply crankshaft angled from the maximum pressure point (C)to the maximum temperature point (D). Figure 4.2 The relationship between (4)Supplement combustion period:This cylinder pressure and crankshaft angle period is from the maximum temperature point I--Fire delay period II--Rapid combustion period (D))to the end of the combustion process point III--Slow combustion period (E) IV--Supplement combustion period 械电子工程学 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 4 Diesel fuel supply system 1. Formation and Combustion of Combustible Mixture According to the variation feature of the cylinder temperature and pressure,the formation and combustion of diesel engine mixture can be divided into four periods according to the crank angle: (1) Fire delay period: This period is from the fuel injected into the cylinder the starting point (A) to beginning fire point (B) (Fire delay). (2) Rapid combustion period: This period starting from the beginning fire point (B) to rapidly burning until the maximum pressure point (C). (3) Slow combustion period: This period is from the maximum pressure point (C) to the maximum temperature point (D). (4) Supplement combustion period: This period is from the maximum temperature point (D) ) to the end of the combustion process point (E). Figure 4.2 The relationship between cylinder pressure and crankshaft angle Ⅰ-- Fire delay period Ⅱ-- Rapid combustion period Ⅲ --Slow combustion period Ⅳ--Supplement combustion period Section 2 Mixture formation and combustion chamber

Chapter 4 Diesel fuel supply system Section 2 Mixture formation and combustion chambep The requirements of diesel engine fuel supply system: (1)Moderate concentration of combustible mixture. (2)Injection pressure must be high enough. (3)Injection law of diesel injection system should correspond with the combustion process. (4)Strong vortex motion of air in the combustion chamber. 2.Diesel Engine Combustion Chamber According to structural type,diesel engine combustion chamber can be divided into two categories:uniform combustion chamber and separate combustion chamber. 业机被对电子工程膜 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 4 Diesel fuel supply system The requirements of diesel engine fuel supply system : (1) Moderate concentration of combustiblemixture. (2) Injection pressure must be high enough. (3)Injection law of diesel injection system should correspond with the combustion process. (4) Strong vortex motion of air in the combustion chamber. 2. Diesel Engine Combustion Chamber According to structural type, diesel engine combustion chamber can be divided into two categories: uniform combustion chamber and separate combustion chamber. Section 2 Mixture formation and combustion chamber

Chapter 4 Diesel fuel supply system Section 2 Mixture formation and combustion chamber 2.1 Uniform combustion chamber (a】 (b) Figure 4.3 Uniform combustion chamber (a)o-type (b)sphere type (c)helical intake port vortex motion of air schematic diagram 业机械电子工程学 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 4 Diesel fuel supply system Figure 4.3 Uniform combustion chamber (a) ω-type (b) sphere type (c) helical intake port vortex motion of air schematic diagram 2.1 Uniform combustion chamber Section 2 Mixture formation and combustion chamber

Chapter 4 Diesel fuel supply system Section 2 Mixture formation and combustion chambep Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 4 Diesel fuel supply system Section 2 Mixture formation and combustion chamber

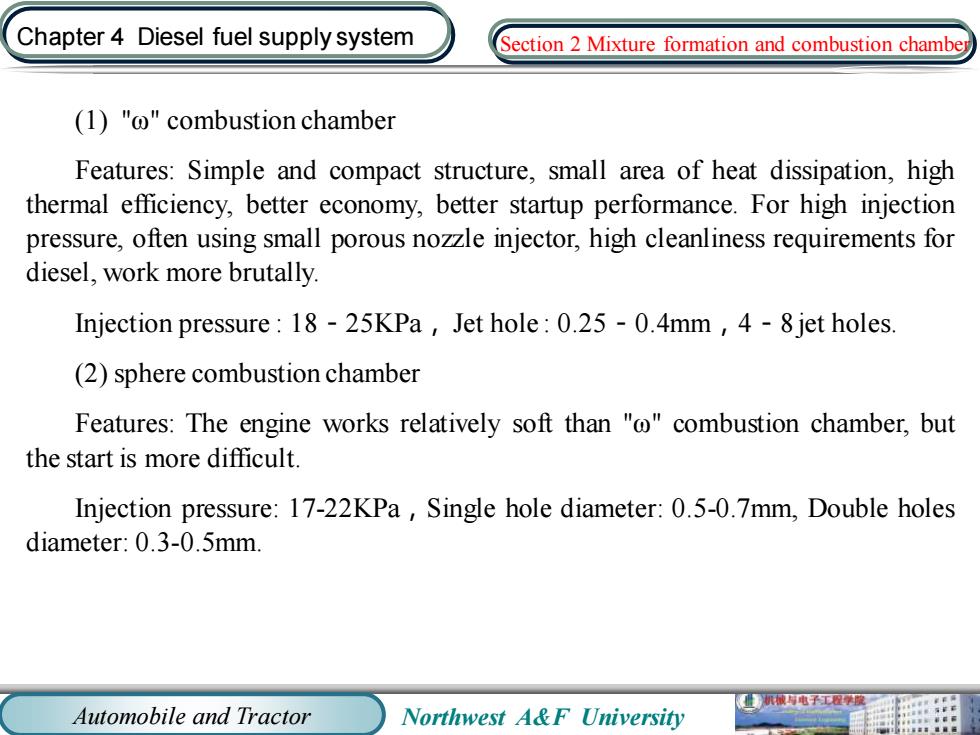

Chapter 4 Diesel fuel supply system Section 2 Mixture formation and combustion chamber (1)"@"combustion chamber Features:Simple and compact structure,small area of heat dissipation,high thermal efficiency,better economy,better startup performance.For high injection pressure,often using small porous nozzle injector,high cleanliness requirements for diesel,work more brutally. Injection pressure:18-25KPa Jet hole:0.25-0.4mm 4-8jet holes. (2)sphere combustion chamber Features:The engine works relatively soft than "o"combustion chamber,but the start is more difficult. Injection pressure:17-22KPa Single hole diameter:0.5-0.7mm,Double holes diameter:0.3-0.5mm. 械电子工程学 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 4 Diesel fuel supply system (1) "ω" combustion chamber Features: Simple and compact structure, small area of heat dissipation, high thermal efficiency, better economy, better startup performance. For high injection pressure, often using small porous nozzle injector, high cleanliness requirements for diesel, work more brutally. Injection pressure : 18-25KPa,Jet hole : 0.25-0.4mm,4-8 jet holes. (2) sphere combustion chamber Features: The engine works relatively soft than "ω" combustion chamber, but the start is more difficult. Injection pressure: 17-22KPa,Single hole diameter: 0.5-0.7mm, Double holes diameter: 0.3-0.5mm. Section 2 Mixture formation and combustion chamber

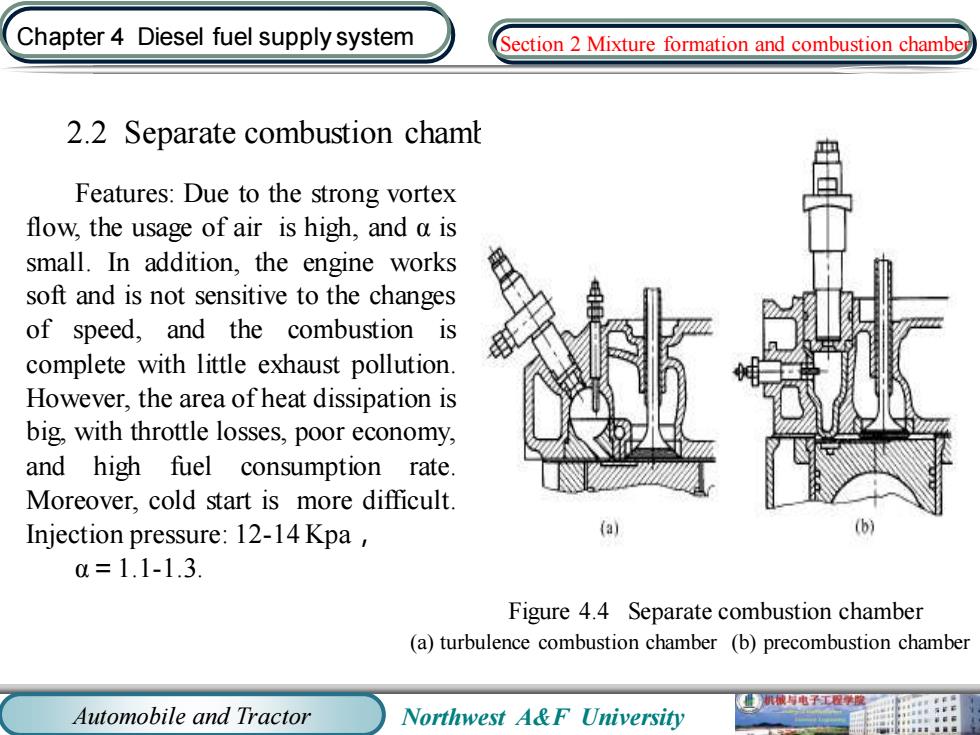

Chapter 4 Diesel fuel supply system Section 2 Mixture formation and combustion chambep 2.2 Separate combustion chamb Features:Due to the strong vortex flow,the usage of air is high,and a is small.In addition,the engine works soft and is not sensitive to the changes of speed,and the combustion is complete with little exhaust pollution However,the area of heat dissipation is big,with throttle losses,poor economy, and high fuel consumption rate. Moreover,cold start is more difficult Injection pressure:12-14 Kpa, 0=1.1-1.3. Figure 4.4 Separate combustion chamber (a)turbulence combustion chamber (b)precombustion chamber 机被电子工程聚 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 4 Diesel fuel supply system 2.2 Separate combustion chamber Features: Due to the strong vortex flow, the usage of air is high, and α is small. In addition, the engine works soft and is not sensitive to the changes of speed, and the combustion is complete with little exhaust pollution. However, the area of heat dissipation is big, with throttle losses, poor economy, and high fuel consumption rate. Moreover, cold start is more difficult. Injection pressure: 12-14 Kpa, α=1.1-1.3. Figure 4.4 Separate combustion chamber (a) turbulence combustion chamber (b) precombustion chamber Section 2 Mixture formation and combustion chamber

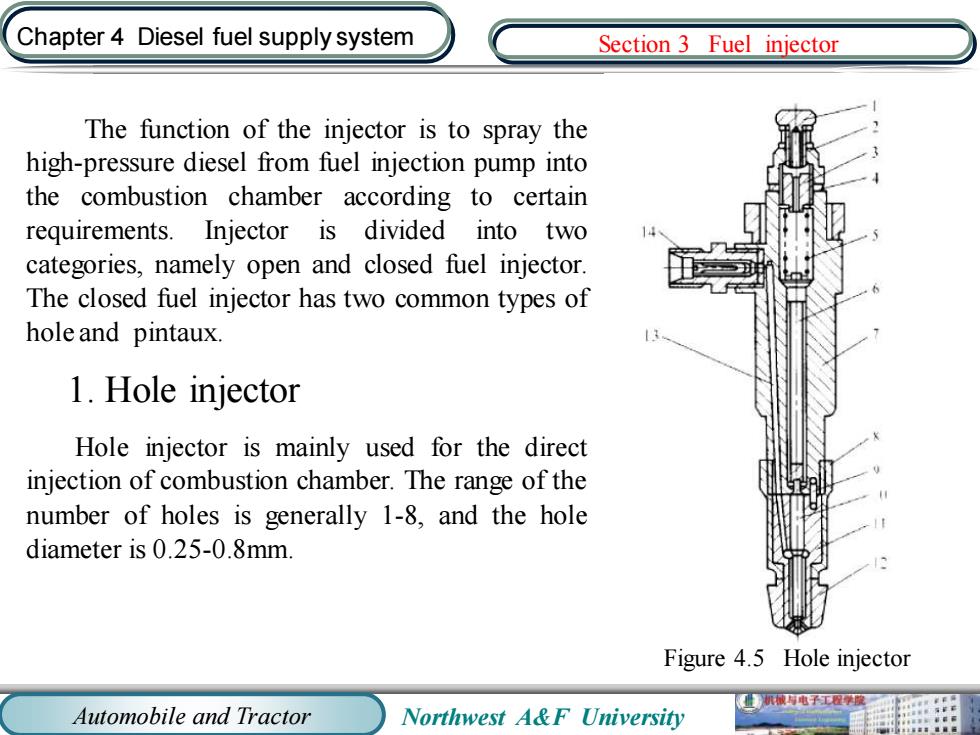

Chapter 4 Diesel fuel supply system Section 3 Fuel injector The function of the injector is to spray the high-pressure diesel from fuel injection pump into the combustion chamber according to certain requirements.Injector is divided into t two categories,namely open and closed fuel injector. The closed fuel injector has two common types of hole and pintaux. 1.Hole injector Hole injector is mainly used for the direct injection of combustion chamber.The range of the number of holes is generally 1-8,and the hole diameter is 0.25-0.8mm. Figure 4.5 Hole injector 机电子工程膜 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 4 Diesel fuel supply system The function of the injector is to spray the high-pressure diesel from fuel injection pump into the combustion chamber according to certain requirements. Injector is divided into two categories, namely open and closed fuel injector. The closed fuel injector has two common types of hole and pintaux. 1. Hole injector Hole injector is mainly used for the direct injection of combustion chamber. The range of the number of holes is generally 1-8, and the hole diameter is 0.25-0.8mm. Figure 4.5 Hole injector Section 3 Fuel injector

Chapter 4 Diesel fuel supply system Section 3 Fuel injector (b) Figure 4.6 The working process of hole injector schematic diagram (a)fuel injection (b)close Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 4 Diesel fuel supply system Figure 4.6 The working process of hole injector schematic diagram (a)fuel injection (b)close Section 3 Fuel injector

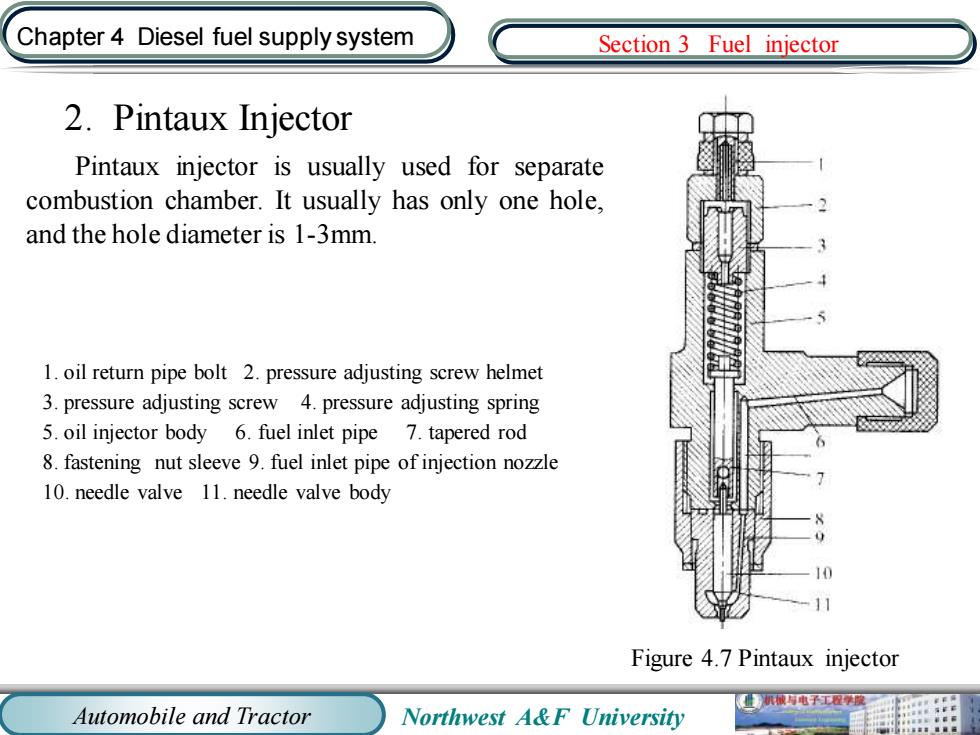

Chapter 4 Diesel fuel supply system Section 3 Fuel injector 2.Pintaux Injector Pintaux injector is usually used for separate combustion chamber.It usually has only one hole, and the hole diameter is 1-3mm. 1.oil return pipe bolt 2.pressure adjusting screw helmet 3.pressure adjusting screw 4.pressure adjusting spring 5.oil injector body 6.fuel inlet pipe 7.tapered rod 8.fastening nut sleeve 9.fuel inlet pipe of injection nozzle 10.needle valve 11.needle valve body 10 Figure 4.7 Pintaux injector Automobile and Tractor Northwest A&F University 电子用

Automobile and Tractor Northwest A&F University Chapter 4 Diesel fuel supply system 2. Pintaux Injector Pintaux injector is usually used for separate combustion chamber. It usually has only one hole, and the hole diameter is 1-3mm. Figure 4.7 Pintaux injector 1. oil return pipe bolt 2. pressure adjusting screw helmet 3. pressure adjusting screw 4. pressure adjusting spring 5. oil injector body 6. fuel inlet pipe 7. tapered rod 8. fastening nut sleeve 9. fuel inlet pipe of injection nozzle 10. needle valve 11. needle valve body Section 3 Fuel injector