Chapter 2 Crank-connecting rod mechanism and parts Section 1 Engine body group The engine body group consists mainly of engine body. cylinder jacket, cylinder cap,cylinder gasket and lower crankcase. 1.Engine Body and Lower Crankcase (1)Engine body The common forms of the engine body structure have the general type,gantry type and tunnel-type. Figure 2.1 The forms of the engine body structure 1.cylinder block 2.water jacket 3.camshaft hole seat 4.reinforcing rib 5.cylinder jacket 6.main bearing seat 7.main bearing seat hole 8.working surface of installing oil pan 9.working surface of installing main bearing cap 机械电子工程学度 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 2 Crank-connecting rod mechanism and parts The engine body group consists mainly of engine body、 cylinder jacket, cylinder cap, cylinder gasket and lower crankcase. 1. Engine Body and Lower Crankcase Section 1 Engine body group (1) Engine body The common forms of the engine body structure have the general type, gantry type and tunnel-type. Figure 2.1 The forms of the engine body structure 1. cylinder block 2. water jacket 3. camshaft hole seat 4. reinforcing rib 5. cylinder jacket 6. main bearing seat 7. main bearing seat hole 8. working surface of installing oil pan 9. working surface of installing main bearing cap

Chapter 2 Crank-connecting rod mechanism and parts Section 1 Engine body group (2)Lower crankcase It is often called oil pan,which is installed in the lower part of the body that is filled with oil for lubrication. 2.Cylinder and Cylinder Jacket (1)Cylinder Cylindrical cavity,which is guiding the movement of the piston in it is called cylinder. Cylinder must meet the demands of high temperature resistance,abrasion resistance and corrosion resistance. Generally adopting high quality gray cast iron or high quality alloy cast iron of cast iron by adding a small amount of nickel,molybdenum and other elements. Making cylinder and the body as a whole one is very few,mostly adopting the removable modular structure of the cylinder and body,that is,cylinder jacket made of high-quality materials is inlaid into the cylinder body of the body. 机械特电子工程学理 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 2 Crank-connecting rod mechanism and parts (2) Lower crankcase It is often called oil pan, which is installed in the lower part of the body that is filled with oil for lubrication. 2. Cylinder and Cylinder Jacket (1) Cylinder Cylindrical cavity,which is guiding the movement of the piston in it ,is called cylinder. Cylinder must meet the demands of high temperature resistance、 abrasion resistance and corrosion resistance. Generally adopting high quality gray cast iron or high quality alloy cast iron of cast iron by adding a small amount of nickel, molybdenumand other elements. Making cylinder and the body as a whole one is very few, mostly adopting the removable modular structure of the cylinder and body, that is, cylinder jacket made of high-qualitymaterials is inlaid into the cylinder body of the body. Section 1 Engine body group

Chapter 2 Crank-connecting rod mechanism and parts Section 1 Engine body group (2)Cylinder jacket Water-cooled internal combustion engine cylinder jacket has wet and dry-wet cylinder jacket. Wet cylinder jacket extine contacts directly with the cooling water,which can achieve good heat dissipation,uniform cooling,easily processed,and easy assembly. jacket thickness 5-9 mm. Dry cylinder jacket extine does not contact directly with the cooling water.Heat dissipation is poor,the outer circle of cylinder jacket and the inner hole of the cylinder block must be finishing,and assembly is not convenient.However,the structure is compact,tightness is good,and intensity and stiffness of the body are very high after dry cylinder jacket is loaded.jacket thickness 1-3 mm. 械电子工程学 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 2 Crank-connecting rod mechanism and parts Wet cylinder jacket extine contacts directly with the cooling water, which can achieve good heat dissipation, uniform cooling, easily processed, and easy assembly. jacket thickness 5-9 mm. Dry cylinder jacket extine does not contact directly with the cooling water. Heat dissipation is poor, the outer circle of cylinder jacket and the inner hole of the cylinder block must be finishing, and assembly is not convenient. However, the structure is compact , tightness is good, and intensity and stiffness of the body are very high after dry cylinder jacket is loaded.jacket thickness 1-3 mm. (2) Cylinder jacket Water-cooled internal combustion engine cylinder jacket has wet and dry-wet cylinder jacket. Section 1 Engine body group

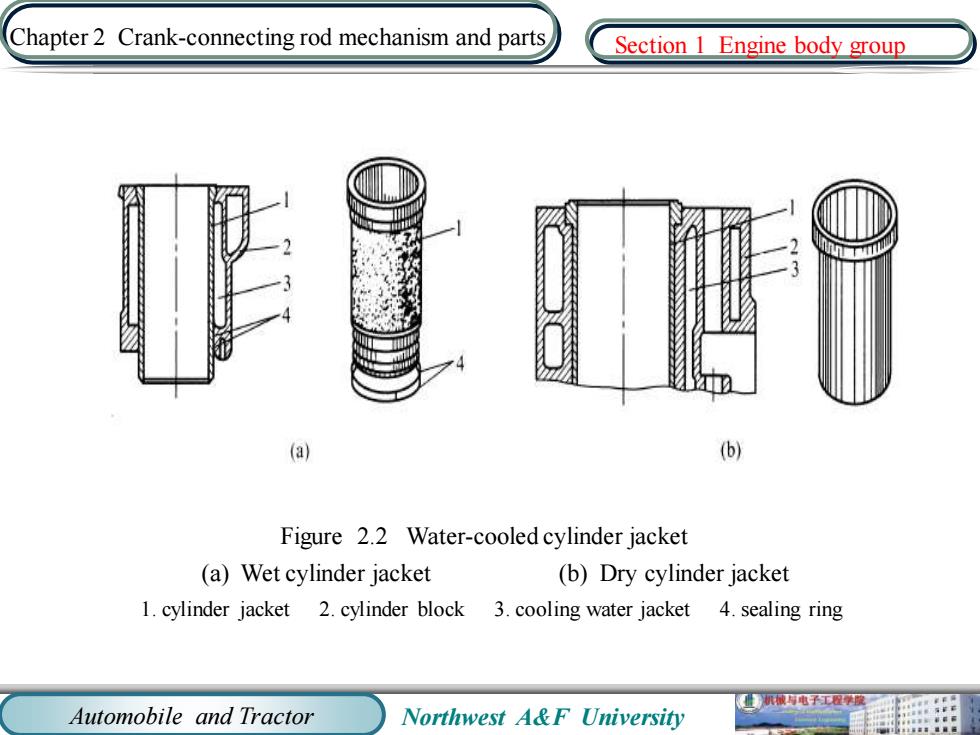

Chapter 2 Crank-connecting rod mechanism and parts Section 1 Engine body group (a) (b) Figure 2.2 Water-cooled cylinder jacket (a)Wet cylinder jacket (b)Dry cylinder jacket 1.cylinder jacket 2.cylinder block 3.cooling water jacket 4.sealing ring 机械与电子工程度 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 2 Crank-connecting rod mechanism and parts Figure 2.2 Water-cooled cylinder jacket (a) Wet cylinder jacket (b) Dry cylinder jacket 1. cylinder jacket 2. cylinder block 3. cooling water jacket 4. sealing ring Section 1 Engine body group

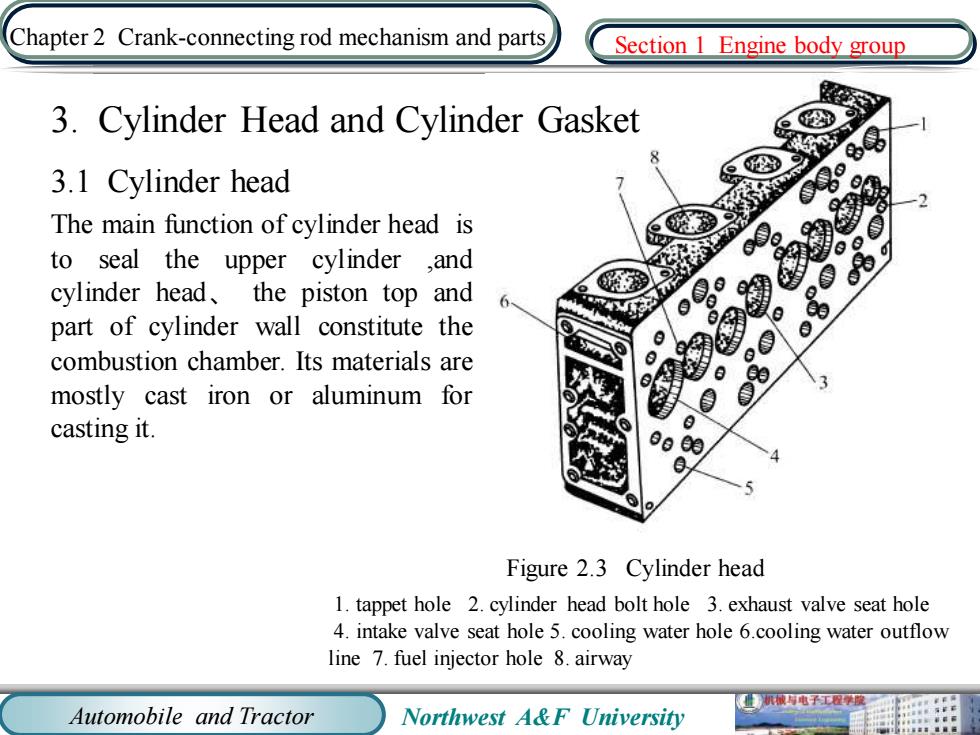

Chapter 2 Crank-connecting rod mechanism and parts Section 1 Engine body group 3.Cylinder Head and Cylinder Gasket 3.1 Cylinder head The main function of cylinder head is ⊙ to seal the upper cylinder ,and cylinder head,the piston top and part of cylinder wall constitute the combustion chamber.Its materials are mostly cast iron or aluminum for 9 casting it. Figure 2.3 Cylinder head 1.tappet hole 2.cylinder head bolt hole 3.exhaust valve seat hole 4.intake valve seat hole 5.cooling water hole 6.cooling water outflow line 7.fuel injector hole 8.airway 业机械电子工程学度 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 2 Crank-connecting rod mechanism and parts 3. Cylinder Head and Cylinder Gasket 3.1 Cylinder head The main function of cylinder head is to seal the upper cylinder ,and cylinder head、 the piston top and part of cylinder wall constitute the combustion chamber. Its materials are mostly cast iron or aluminum for casting it. Figure 2.3 Cylinder head 1. tappet hole 2. cylinder head bolt hole 3. exhaust valve seat hole 4. intake valve seat hole 5. cooling water hole 6.cooling water outflow line 7. fuel injector hole 8. airway Section 1 Engine body group

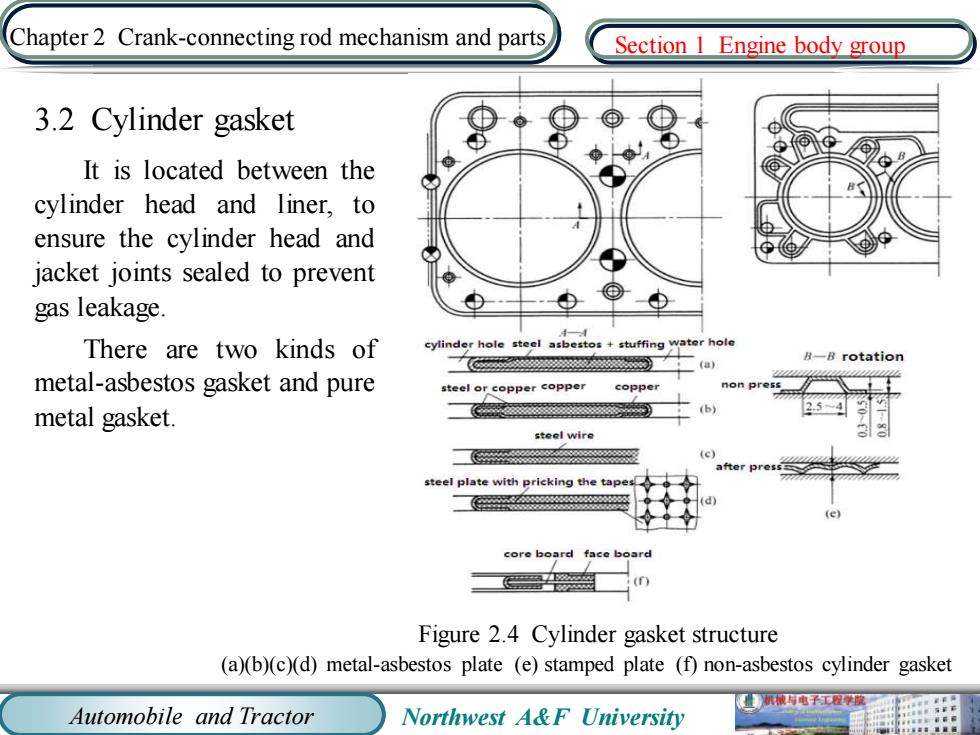

Chapter 2 Crank-connecting rod mechanism and parts Section 1 Engine body group 3.2 Cylinder gasket ④ ④®④ It is located between the cylinder head and liner,to ensure the cylinder head and jacket joints sealed to prevent gas leakage. There are two kinds of inder holetfin ter hole B-B rotation metal-asbestos gasket and pure steel or copper copper copper on pre metal gasket. (b steel wire 【 steel plate with pricking the tapes 【 core board face board 密 Figure 2.4 Cylinder gasket structure (a)(b)(c)(d)metal-asbestos plate (e)stamped plate (f)non-asbestos cylinder gasket 机械持电子工程膜 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 2 Crank-connecting rod mechanism and parts 3.2 Cylinder gasket It is located between the cylinder head and liner, to ensure the cylinder head and jacket joints sealed to prevent gas leakage. There are two kinds of metal-asbestos gasket and pure metal gasket. Figure 2.4 Cylinder gasket structure (a)(b)(c)(d) metal-asbestos plate (e) stamped plate (f) non-asbestos cylinder gasket Section 1 Engine body group

Chapter 2 Crank-connecting rod mechanism and parts Section 1 Engine body group 3.3 Cylinder head bolt The number of bolts are as much as possible,and the diameter of bolt is appropriately smaller,which ensures uniform force.Preload of bolts should be 3-4 times larger than the maximum gas pressure in cylinder head.Screwing the bolts is symmetrically from the middle several times alternately to the surrounding. 8日。。8.88 19 02 1 03 o20o180120907011014o18 (a) (b) Figure 2.5 Cylinder head bolt tightening sequence (a)4125-type internal combustion engine (b)495-type internal combustion engine 械电子工程学 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 2 Crank-connecting rod mechanism and parts 3.3 Cylinder head bolt The number of bolts are as much as possible, and the diameter of bolt is appropriately smaller, which ensures uniform force. Preload of bolts should be 3-4 times larger than the maximum gas pressure in cylinder head. Screwing the bolts is symmetrically from the middle several times alternately to the surrounding. Figure 2.5 Cylinder head bolt tightening sequence (a) 4125-type internal combustion engine (b) 495-type internal combustion engine Section 1 Engine body group

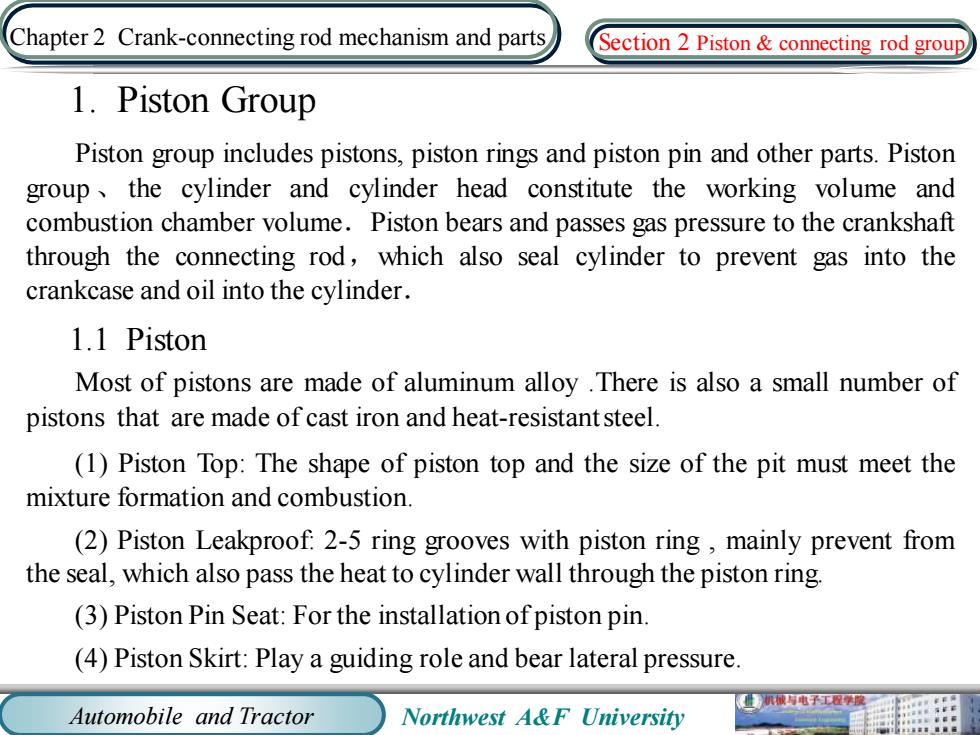

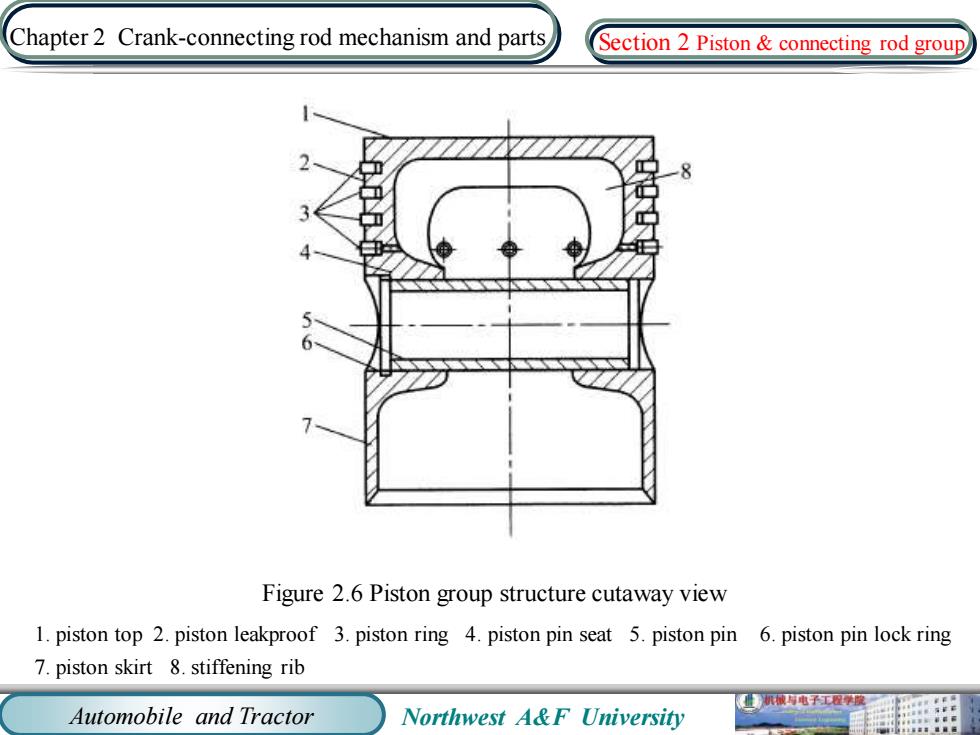

Chapter 2 Crank-connecting rod mechanism and parts Section 2 Piston connecting rod group 1.Piston Group Piston group includes pistons,piston rings and piston pin and other parts.Piston group the cylinder and cylinder head constitute the working volume and combustion chamber volume.Piston bears and passes gas pressure to the crankshaft through the connecting rod,which also seal cylinder to prevent gas into the crankcase and oil into the cylinder. 1.1 Piston Most of pistons are made of aluminum alloy.There is also a small number of pistons that are made of cast iron and heat-resistant steel. (1)Piston Top:The shape of piston top and the size of the pit must meet the mixture formation and combustion. (2)Piston Leakproof:2-5 ring grooves with piston ring,mainly prevent from the seal,which also pass the heat to cylinder wall through the piston ring. (3)Piston Pin Seat:For the installation of piston pin. (4)Piston Skirt:Play a guiding role and bear lateral pressure. 业机被寿电子工程聚 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 2 Crank-connecting rod mechanism and parts 1. Piston Group Piston group includes pistons, piston rings and piston pin and other parts. Piston group 、 the cylinder and cylinder head constitute the working volume and combustion chamber volume.Piston bears and passes gas pressure to the crankshaft through the connecting rod,which also seal cylinder to prevent gas into the crankcase and oil into the cylinder. 1.1 Piston Most of pistons are made of aluminum alloy .There is also a small number of pistons that are made of cast iron and heat-resistantsteel. (1) Piston Top: The shape of piston top and the size of the pit must meet the mixture formation and combustion. (2) Piston Leakproof: 2-5 ring grooves with piston ring , mainly prevent from the seal, which also pass the heat to cylinder wall through the piston ring. (3) Piston Pin Seat: For the installation of piston pin. (4) Piston Skirt: Play a guiding role and bear lateral pressure. Section 2 Piston & connecting rod group

Chapter 2 Crank-connecting rod mechanism and parts Section 2 Piston connecting rod group Figure 2.6 Piston group structure cutaway view 1.piston top 2.piston leakproof 3.piston ring 4.piston pin seat 5.piston pin 6.piston pin lock ring 7.piston skirt 8.stiffening rib 机械电子工程二 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 2 Crank-connecting rod mechanism and parts Figure 2.6 Piston group structure cutaway view 1. piston top 2. piston leakproof 3. piston ring 4. piston pin seat 5. piston pin 6. piston pin lock ring 7. piston skirt 8. stiffening rib Section 2 Piston & connecting rod group

Chapter 2 Crank-connecting rod mechanism and parts Section 2 Piston connecting rod group Two-stroke gasoline engines mostly use convex top piston. Four-stroke gasoline engines mostly use flat top piston,and also with concave top piston. Regular four-stroke diesel engine piston is designed into a variety of pits. (a】 (b】 (d) (e) (f) Figure 2.7 Piston top shape schematic diagram (a)flat top (b)concave top (c)convex top (d)(e)(f)concave pit 机被与电子工程学聚 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 2 Crank-connecting rod mechanism and parts Two-stroke gasoline engines mostly use convex top piston. Four-stroke gasoline engines mostly use flat top piston, and also with concave top piston. Regular four-stroke diesel engine piston is designed into a variety of pits. Figure 2.7 Piston top shape schematic diagram (a) flat top (b) concave top (c) convex top (d) (e) (f) concave pit Section 2 Piston & connecting rod group