学校代码:10246 学号:11210720122 復大孥 硕士学位论文 CMOS带隙基准源研究 院 系: 信息科学与工程学院 专 业: 集成电路工程 姓 名: 刘玉琰 指导教师: 唐长文 完成日期: 2013年5月16日

学校代码: 10246 学 号: 11210720122 硕 士 学 位 论 文 CMOS 带隙基准源研究 院 系: 信息科学与工程学院 专 业: 集成电路工程 姓 名: 刘玉琰 指 导 教 师: 唐长文 完 成 日 期: 2013 年 5 月 16 日

目录 图目录… 表目录… …V 摘要… VIl Abstract................... 第一章概述… …1 1.1课题背景… …1 1.2论文主要工作… …2 1.3论文组织结构 …4 第二章带隙基准源原理… …5 2.1前言… …5 2.2带隙基准电压源原理 5 2.2.1概述… .…5 2.2.2负温度系数电压 6 2.2.3正温度系数电压… …7 2.2.4带隙基准电压源 …8 2.2.5典型电路分析… 10 2.3带隙基准电流源原理… 11 第三章带隙基准电压源电路实现 …15 3.1前言 15 3.2电路结构分析 16 3.2.1启动电路分析… 18 3.2.2误差放大器分析… 19 3.2.3带隙基准电压源核心电路分析 20 3.2.4数字修正及RC滤波分析 21 3.3电路性能分析… 22 3.3.1误差分析 23 3.3.2温度系数分析… 24 3.3.3噪声分析… 26 3.3.4电源抑制比分析 27 3.4仿真结果… 29 3.4.1直流特性… 29 3.4.2交流特性… 32 3.4.3噪声特性… 33

I 目 录 图目录 ························································································ III 表目录 ························································································ V 摘 要 ······················································································· VII Abstract····················································································· IX 第一章 概述 ················································································ 1 1.1 课题背景 ·········································································· 1 1.2 论文主要工作 ···································································· 2 1.3 论文组织结构 ···································································· 4 第二章 带隙基准源原理 ································································· 5 2.1 前言 ················································································ 5 2.2 带隙基准电压源原理 ··························································· 5 2.2.1 概述 ······································································· 5 2.2.2 负温度系数电压 ························································ 6 2.2.3 正温度系数电压 ························································ 7 2.2.4 带隙基准电压源 ························································ 8 2.2.5 典型电路分析 ························································· 10 2.3 带隙基准电流源原理 ························································· 11 第三章 带隙基准电压源电路实现 ···················································· 15 3.1 前言 ·············································································· 15 3.2 电路结构分析 ·································································· 16 3.2.1 启动电路分析 ························································· 18 3.2.2 误差放大器分析 ······················································ 19 3.2.3 带隙基准电压源核心电路分析 ···································· 20 3.2.4 数字修正及 RC 滤波分析 ·········································· 21 3.3 电路性能分析 ·································································· 22 3.3.1 误差分析 ······························································· 23 3.3.2 温度系数分析 ························································· 24 3.3.3 噪声分析 ······························································· 26 3.3.4 电源抑制比分析 ······················································ 27 3.4 仿真结果 ········································································ 29 3.4.1 直流特性 ······························································· 29 3.4.2 交流特性 ······························································· 32 3.4.3 噪声特性 ······························································· 33

3.4.4电源抑制比特性 35 3.4.5瞬态特性 37 3.4.6数字修正特性… 39 3.5总结… 39 第四章电压-电流转换电路实现… …41 4.1前言… 41 4.2电路结构及性能分析… 41 4.3仿真结果… 43 4.4总结…… 44 第五章温度传感电路实现… 45 5.1前言… 45 5.2电路结构及性能分析 45 5.3仿真结果… 46 5.4总结… 47 第六章版图设计及后仿真… 49 6.1版图设计的基本考虑… 49 6.2带隙基准电压源电路版图实现 …50 6.2.1带隙基准电压源的版图设计 50 6.2.2后仿真… 50 6.3电压-电流转换电路版图实现… 52 6.3.1电压-电流转换电路的版图设计 52 63.2后仿真… 53 6.4温度传感器电路版图实现 54 6.4.1温度传感器电路的版图设计…54 6.4.2后仿真… 54 第七章总结与展望… 57 71总结… 57 7.2展望… 57 致谢 59 参考文献… 61

II 3.4.4 电源抑制比特性 ······················································ 35 3.4.5 瞬态特性 ······························································· 37 3.4.6 数字修正特性 ························································· 39 3.5 总结 ·············································································· 39 第四章 电压–电流转换电路实现 ···················································· 41 4.1 前言 ·············································································· 41 4.2 电路结构及性能分析 ························································· 41 4.3 仿真结果 ········································································ 43 4.4 总结 ·············································································· 44 第五章 温度传感电路实现 ···························································· 45 5.1 前言 ·············································································· 45 5.2 电路结构及性能分析 ························································· 45 5.3 仿真结果 ········································································ 46 5.4 总结 ·············································································· 47 第六章 版图设计及后仿真 ···························································· 49 6.1 版图设计的基本考虑 ························································· 49 6.2 带隙基准电压源电路版图实现 ············································· 50 6.2.1 带隙基准电压源的版图设计 ······································· 50 6.2.2 后仿真 ·································································· 50 6.3 电压-电流转换电路版图实现 ··············································· 52 6.3.1 电压-电流转换电路的版图设计 ··································· 52 6.3.2 后仿真 ·································································· 53 6.4 温度传感器电路版图实现 ··················································· 54 6.4.1 温度传感器电路的版图设计 ······································· 54 6.4.2 后仿真 ·································································· 54 第七章 总结与展望 ····································································· 57 7.1 总结 ·············································································· 57 7.2 展望 ·············································································· 57 致谢 ·························································································· 59 参考文献 ···················································································· 61

图目录 图1-1带隙基准源系统结构…2 图1-2带隙基准电压源重要参数及性能图示…3 图2-1理想电流和电压的伏安特性曲线…5 图2-2负温度系数电压…6 图2-3PTAT电压产生电路…7 图2-4发射极面积不同的PTAT电压产生电路…8 图2-5带隙基准的一般原理…9 图2-6带隙基准正负温度曲线加权…9 图2-7带隙基准源输出电压随温度变化曲线 10 图2-8一个传统的带隙基准电压源电路… …10 图2-9PTAT电流的生成… 12 图2-10采用简单放大器生成PTAT电流· …12 图2-11与温度无关的电压的生成… 12 图2-12电压-电流转换电路原理图… …13 图3-1带隙基准电压源电路原理图… 17 图3-2启动电路的电路结构…。 18 图3-3误差放大器的电路结构… 19 图3-4带隙基准电压源核心电路的电路结构 … 20 图3-5数字铺助控制电路的电路结构…21 图3-6RC滤波器的频率特性 …… 22 图3-7带隙基准电压源电路中误差源的分类…22 图3-8引起带隙基准电压源电路误差的因素 24 图3-9温度系数曲线…24 图3-10带隙基准电压源的等效噪声电路。 26 图3-11使用并联反馈调节输出电压的电路结构…28 图3-12直观的PSRR分析模型…28 图3-13直观的PSRR分析模型… 29 图3-13电源电压变化对温度曲线的影响…29 图3-14工艺角的变化对温度曲线的影响 30 图3-15电源电压变化对环路增益的影响…32 图3-16电源电压变化对环路相位裕度的影响… 32 图3-17工艺角的变化对环路增益的影响…33 图3-18工艺角的变化对环路相位裕度的影响…… 33 2

III 图目录 图 1–1 带隙基准源系统结构····························································· 2 图 1–2 带隙基准电压源重要参数及性能图示 ········································ 3 图 2–1 理想电流和电压的伏安特性曲线 ·············································· 5 图 2–2 负温度系数电压··································································· 6 图 2–3 PTAT 电压产生电路······························································ 7 图 2–4 发射极面积不同的 PTAT 电压产生电路 ····································· 8 图 2–5 带隙基准的一般原理····························································· 9 图 2–6 带隙基准正负温度曲线加权 ···················································· 9 图 2–7 带隙基准源输出电压随温度变化曲线 ······································ 10 图 2–8 一个传统的带隙基准电压源电路 ············································ 10 图 2–9 PTAT 电流的生成······························································· 12 图 2–10 采用简单放大器生成 PTAT 电流 ·········································· 12 图 2–11 与温度无关的电压的生成 ··················································· 12 图 2–12 电压-电流转换电路原理图 ·················································· 13 图 3–1 带隙基准电压源电路原理图 ·················································· 17 图 3–2 启动电路的电路结构··························································· 18 图 3–3 误差放大器的电路结构························································ 19 图 3–4 带隙基准电压源核心电路的电路结构 ······································ 20 图 3–5 数字铺助控制电路的电路结构 ··············································· 21 图 3–6 RC 滤波器的频率特性 ························································ 22 图 3–7 带隙基准电压源电路中误差源的分类 ······································ 22 图 3–8 引起带隙基准电压源电路误差的因素 ······································ 24 图 3–9 温度系数曲线···································································· 24 图 3–10 带隙基准电压源的等效噪声电路 ·········································· 26 图 3–11 使用并联反馈调节输出电压的电路结构 ································· 28 图 3–12 直观的 PSRR 分析模型 ····················································· 28 图 3–13 直观的 PSRR 分析模型 ····················································· 29 图 3–13 电源电压变化对温度曲线的影响 ·········································· 29 图 3–14 工艺角的变化对温度曲线的影响 ·········································· 30 图 3–15 电源电压变化对环路增益的影响 ·········································· 32 图 3–16 电源电压变化对环路相位裕度的影响 ···································· 32 图 3–17 工艺角的变化对环路增益的影响 ·········································· 33 图 3–18 工艺角的变化对环路相位裕度的影响 ···································· 33

图3-19电源电压变化对噪声的影响… 34 图3-20工艺角的变化对噪声的影响…34 图3-21无RC滤波时电源电压变化对PSR的影响 35 图3-22有RC滤波时电源电压变化对PSR的影响…35 图3-23VDD为2.1V有RC滤波时工艺角的变化对PSR特性的影响…36 图3-24VDD为3.3V有RC滤波时工艺角的变化对PSR特性的影响…36 图3-25电源电压为3.3V时的瞬态特性 37 图3-26电源电压变化对瞬态特性的影响… 37 图3-27VD为2.1V时工艺角的变化对瞬态特性的影响…38 图3-28Vb加为3.3V时工艺角的变化对瞬态特性的影响 38 图3-29带隙基准电压源的建立时间…38 图3-30数字修正电路正对温度曲线的影响 39 图4-1电流镜结构示意图… …41 图4-2电压-电流转换电路… 42 图4-3电阻阵列电路… 42 图4-4环路交流特性… 43 图45PSRR特性… 43 图4-6工艺角的变化对输出电流的影响…44 图5-1温度传感电路… 45 图5-2环路交流特性… 46 图5-3PSRR特性… 46 图5-4与温度一一对应的输出电压…47 图5-5输出电压曲线的斜率… 47 图6-1带隙基淮电压源电路的版图…50 图6-2带隙基准电压源的前后仿温度曲线对比… 51 图6-3带隙基准电压源的前后仿噪声对比…51 图6-4带隙基准电压源的前后仿电源抑制比对比…52 图6-5电压-电流转换电路的版图……52 图6-6电压-电流转换电路的前后仿输出电流对比…53 图6-7电压-电流转换电路的前后仿电源抑制比对比…53 图6-8温度传感器电路的版图…54 图6-9温度传感器电路的前后仿输出电压对比…54 图6-10温度传感器电路的前后仿输出电压斜率对比…55 图6-11温度传感器电路的前后仿电源抑制比对比… …55

IV 图 3–19 电源电压变化对噪声的影响 ················································ 34 图 3–20 工艺角的变化对噪声的影响 ················································ 34 图 3–21 无 RC 滤波时电源电压变化对 PSR 的影响····························· 35 图 3–22 有 RC 滤波时电源电压变化对 PSR 的影响····························· 35 图 3–23 VDD为 2.1V 有 RC 滤波时工艺角的变化对 PSR 特性的影响 ······· 36 图 3–24 VDD为 3.3V 有 RC 滤波时工艺角的变化对 PSR 特性的影响 ······· 36 图 3–25 电源电压为 3.3V 时的瞬态特性 ··········································· 37 图 3–26 电源电压变化对瞬态特性的影响 ·········································· 37 图 3–27 VDD为 2.1V 时工艺角的变化对瞬态特性的影响 ······················· 38 图 3–28 VDD为 3.3V 时工艺角的变化对瞬态特性的影响 ······················· 38 图 3–29 带隙基准电压源的建立时间 ················································ 38 图 3–30 数字修正电路正对温度曲线的影响 ······································· 39 图 4–1 电流镜结构示意图······························································ 41 图 4–2 电压-电流转换电路····························································· 42 图 4–3 电阻阵列电路···································································· 42 图 4–4 环路交流特性···································································· 43 图 4–5 PSRR 特性 ······································································ 43 图 4–6 工艺角的变化对输出电流的影响 ············································ 44 图 5–1 温度传感电路···································································· 45 图 5–2 环路交流特性···································································· 46 图 5–3 PSRR 特性 ······································································ 46 图 5–4 与温度一一对应的输出电压 ·················································· 47 图 5–5 输出电压曲线的斜率··························································· 47 图 6–1 带隙基准电压源电路的版图 ·················································· 50 图 6–2 带隙基准电压源的前后仿温度曲线对比 ··································· 51 图 6–3 带隙基准电压源的前后仿噪声对比 ········································· 51 图 6–4 带隙基准电压源的前后仿电源抑制比对比 ································ 52 图 6–5 电压-电流转换电路的版图···················································· 52 图 6–6 电压-电流转换电路的前后仿输出电流对比 ······························· 53 图 6–7 电压-电流转换电路的前后仿电源抑制比对比 ···························· 53 图 6–8 温度传感器电路的版图························································ 54 图 6–9 温度传感器电路的前后仿输出电压对比 ··································· 54 图 6–10 温度传感器电路的前后仿输出电压斜率对比 ··························· 55 图 6–11 温度传感器电路的前后仿电源抑制比对比 ······························ 55

表目录 表3-1电源电压变化对温度系数和输出参考电压的影响…30 表3-2电源电压和工艺角的变化对温度系数和输出参考电压的影响…31 表3-3电源电压变化对静态功耗的影响…31 表3-4电源电压和工艺角的变化对静态功耗的影响…31 表3-5电源电压和工艺角的变化对环路交流特性的影响…33 表3-6电源电压和工艺角的变化对噪声特性的影响…34 表3-7电源电压和工艺角的变化对PSR特性的影响…36 表3-8数字修正电路对输出参考电压的影响…39 表3-9带隙基准电压源的性能总结…40 表4-1电压-电流转换电路的性能总结…44 表5-1温度传感电路的性能总结… 47 小

V 表目录 表 3–1 电源电压变化对温度系数和输出参考电压的影响 ······················· 30 表 3–2 电源电压和工艺角的变化对温度系数和输出参考电压的影响 ········ 31 表 3–3 电源电压变化对静态功耗的影响 ············································ 31 表 3–4 电源电压和工艺角的变化对静态功耗的影响 ····························· 31 表 3–5 电源电压和工艺角的变化对环路交流特性的影响 ······················· 33 表 3–6 电源电压和工艺角的变化对噪声特性的影响 ····························· 34 表 3–7 电源电压和工艺角的变化对 PSR 特性的影响 ··························· 36 表 3–8 数字修正电路对输出参考电压的影响 ······································ 39 表 3–9 带隙基准电压源的性能总结 ·················································· 40 表 4–1 电压-电流转换电路的性能总结 ·············································· 44 表 5–1 温度传感电路的性能总结····················································· 47

摘要 随着半导体工艺水平不断提高,集成电路设计技术不断提高,整个半导体行 业迅速发展,应用领域也不断的延伸。与此同时,对各个模块电路的性能要求也 越来越高。基准源为其他电路模块提供稳定精确地电压/电流,其性能影响系统 电路的整体性能。 本文设计的带隙基准电压源对电源电压、工艺和温度的变化不敏感,具有高 电源电压抑制和低噪声的特点。电路中使用数字控制的PNP晶体管阵列对输出参 考电压进行修正,使输出参考电压更加稳定和精确。从仿真结果来看,其温度系 数小于4ppm/℃,Voo为3.3V时直流的电源抑制比为88.9dB,Voo为2.1V时直 流的电源抑制比为65dB。从100Hz到100kHz范围的积分噪声为16.8Vms。 本文设计的电压-电流转换电路由运放、电阻和电流镜构成,将带隙基准电 压产生的输出参考电压转换成稳定的输出电流。电路采用数字可控的电阻,以便 调节电阻得到准确的输出电流。 本文设计的温度传感电路由运放和温度传感核心电路构成。从仿真结果来 看,电路稳定正常工作且实现了输出电压与温度成正比线性关系。 最后本文分别设计了带隙基准电压源电路、电压-电流转换电路和温度传感 器电路的版图,并且通过Cadence对各部分电路进行后仿真。从后仿真结果来看, 对于带隙基准电压源电路,温度系数小于4ppm/℃,Voo为3.3V时直流的电源抑 制比为88.9dB,VoD为2.1V时直流的电源抑制比为65dB。从100Hz到100kHz 范围的积分噪声为16.8μVms。 本文采用台积电的0.18-m CMOS工艺库模型进行仿真。2.1V电源电压下, 功耗为309mW,3.3V电源电压下,功耗为509mW。 关键词:带隙基准电压、电压-电路转换、温度传感、低温度系数、高电源电压 抑制、低噪声、软修正 中图分类号:TN432 VIl

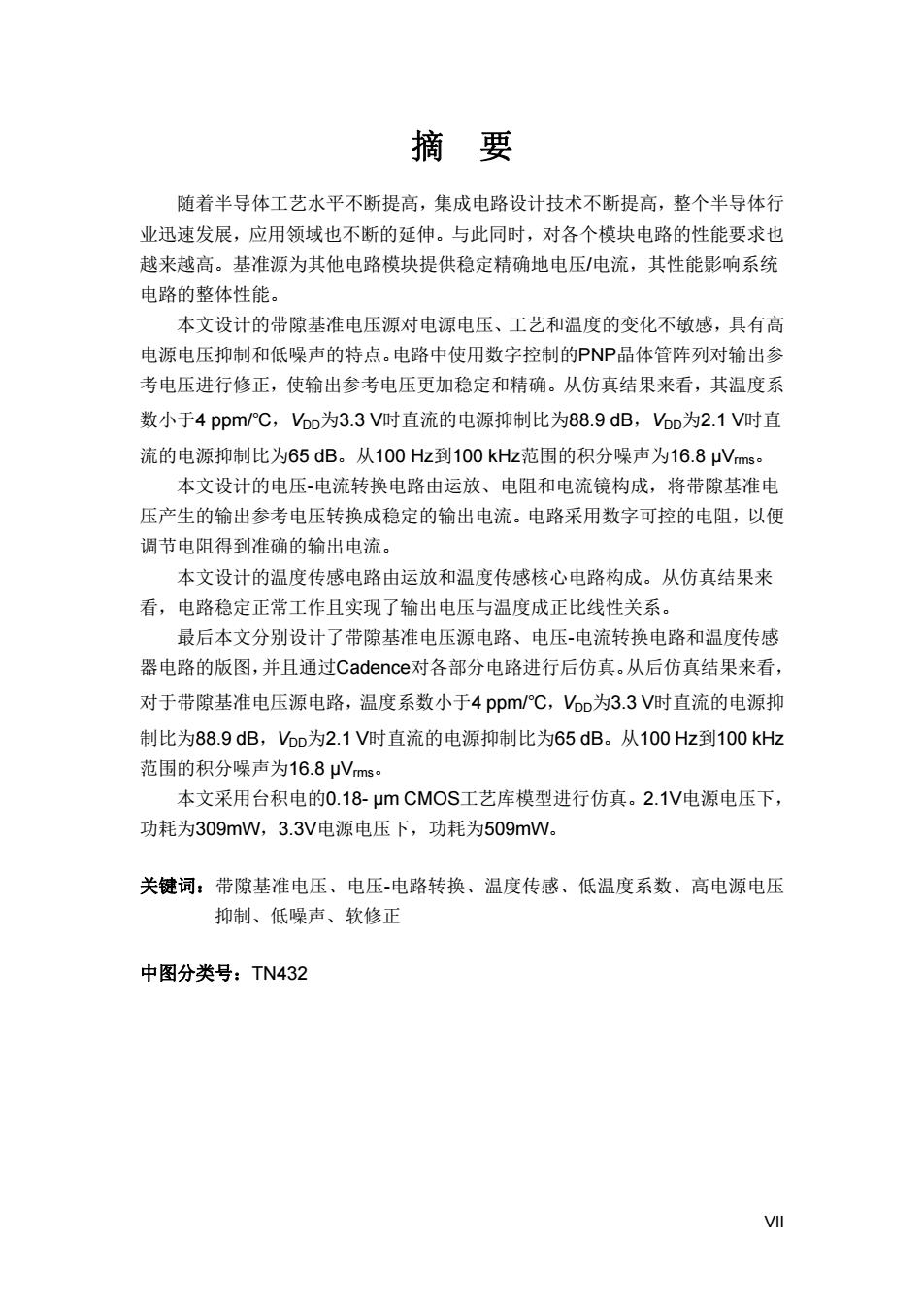

VII 摘 要 随着半导体工艺水平不断提高,集成电路设计技术不断提高,整个半导体行 业迅速发展,应用领域也不断的延伸。与此同时,对各个模块电路的性能要求也 越来越高。基准源为其他电路模块提供稳定精确地电压/电流,其性能影响系统 电路的整体性能。 本文设计的带隙基准电压源对电源电压、工艺和温度的变化不敏感,具有高 电源电压抑制和低噪声的特点。电路中使用数字控制的PNP晶体管阵列对输出参 考电压进行修正,使输出参考电压更加稳定和精确。从仿真结果来看,其温度系 数小于4 ppm/℃,VDD为3.3 V时直流的电源抑制比为88.9 dB,VDD为2.1 V时直 流的电源抑制比为65 dB。从100 Hz到100 kHz范围的积分噪声为16.8 μVrms。 本文设计的电压-电流转换电路由运放、电阻和电流镜构成,将带隙基准电 压产生的输出参考电压转换成稳定的输出电流。电路采用数字可控的电阻,以便 调节电阻得到准确的输出电流。 本文设计的温度传感电路由运放和温度传感核心电路构成。从仿真结果来 看,电路稳定正常工作且实现了输出电压与温度成正比线性关系。 最后本文分别设计了带隙基准电压源电路、电压-电流转换电路和温度传感 器电路的版图,并且通过Cadence对各部分电路进行后仿真。从后仿真结果来看, 对于带隙基准电压源电路,温度系数小于4 ppm/℃,VDD为3.3 V时直流的电源抑 制比为88.9 dB,VDD为2.1 V时直流的电源抑制比为65 dB。从100 Hz到100 kHz 范围的积分噪声为16.8 μVrms。 本文采用台积电的0.18- μm CMOS工艺库模型进行仿真。2.1V电源电压下, 功耗为309mW,3.3V电源电压下,功耗为509mW。 关键词:带隙基准电压、电压-电路转换、温度传感、低温度系数、高电源电压 抑制、低噪声、软修正 中图分类号:TN432

Abstract In recent years,as the level of semiconductor process and the technology of integrated circuit design have improved continuously,the IC industry has been growing rapidly and the application continues to be widely.But at the same time,the performance requirements must be higher.The reference supplies stable and accurate voltage/current for other circuit parts and its performance affects the entire system circuit. In this paper,the bandgap voltage reference is insensitive with the variations of power-supply,process,and temperature,with a high power supply rejection and low noise.There is a digital control circuit to modify the number of the PNP transistor arrays,as a soft-trimming to make the voltage reference more stable and accurate.The simulation results are given,the temperature coefficient is less than 4 ppm/C.When VoD is 3.3 V the PSRR is 88.9 dB at DC,it is 65 dB at 2.1 V at DC.The integrated noise from 100 Hz to 100 kHz is 16.8 uVrms. In this paper,the voltage-current conversion circuit used to convert the reference voltage into a stable and accurate output current covers the Op Amp,controllable resistances and current mirror. In this paper,the temperature sensor circuit constitute by the Op Amp and the temperature sensor core circuit.It is used to compare the output voltage with the temperature. Finally,this paper gives the layout design of the three circuits respectively. The post-simulation results of each part are given,the temperature coefficient is less than 4 ppm/C.When Vop is 3.3 V the PSRR is 88.9 dB at DC,it is 65 dB at 2.1 V at DC.The integrated noise from 100 Hz to 100 kHz is 16.8 uVrms The simulation of this paper is based on the TSMC 0.18-um CMOS process. The power consumption is 340mW at 2.1 V and 540mW at 3.3 V. Keywords:Bandgap Voltage Reference,Voltage-Current Conversion, Low Temperature Coefficient,Temperature Sensor,High PSRR,Low Noise,Soft-trimming Classification Code:TN432 X

IX Abstract In recent years, as the level of semiconductor process and the technology of integrated circuit design have improved continuously, the IC industry has been growing rapidly and the application continues to be widely. But at the same time, the performance requirements must be higher. The reference supplies stable and accurate voltage/current for other circuit parts and its performance affects the entire system circuit. In this paper, the bandgap voltage reference is insensitive with the variations of power-supply, process, and temperature, with a high power supply rejection and low noise. There is a digital control circuit to modify the number of the PNP transistor arrays, as a soft-trimming to make the voltage reference more stable and accurate. The simulation results are given, the temperature coefficient is less than 4 ppm/℃. When VDD is 3.3 V the PSRR is 88.9 dB at DC, it is 65 dB at 2.1 V at DC. The integrated noise from 100 Hz to 100 kHz is 16.8 μVrms. In this paper, the voltage-current conversion circuit used to convert the reference voltage into a stable and accurate output current covers the Op Amp、controllable resistances and current mirror. In this paper, the temperature sensor circuit constitute by the Op Amp and the temperature sensor core circuit. It is used to compare the output voltage with the temperature. Finally, this paper gives the layout design of the three circuits respectively. The post-simulation results of each part are given, the temperature coefficient is less than 4 ppm/℃. When VDD is 3.3 V the PSRR is 88.9 dB at DC, it is 65 dB at 2.1 V at DC. The integrated noise from 100 Hz to 100 kHz is 16.8 μVrms. The simulation of this paper is based on the TSMC 0.18-μm CMOS process. The power consumption is 340mW at 2.1 V and 540mW at 3.3 V. Keywords: Bandgap Voltage Reference,Voltage-Current Conversion, Low Temperature Coefficient,Temperature Sensor,High PSRR,Low Noise,Soft-trimming Classification Code: TN432

第一章概述 第一章概述 1.1课题背景 随着集成电路技术的不断发展,高精度、高速度、超大规模的数字电路设计 和制造变得越来越容易,一些过去由模拟电路实现的功能模块也渐渐的由数字电 路模块替代。但是,这并不意味着模拟电路将会消失。相反,随着数字电路技术 的迅猛发展及设计系统级芯片SOC(System on Chip)技术的流行,模拟电路的重 要性进一步体现[1]。 在模拟集成电路中,广泛地用到一种重要基本单元电路一一基准源,这种基 准是直流量,包括基准电压源和基准电流源。基准源既可以用作电源电压,也可 以为其他电路模块提供精确的参考电压或电流。而且,其性能的好坏直接影响到 整体电路的性能的好坏。例如,差分对的偏置电流必须根据基准产生,因为它会 影响到电路的电压增益和噪声。在模数转换器(ADC)这样的系统中,也需要基准 来确定其输入或输出的全程范围1]。 由于基准随温度的变化和噪声等因素会严重的影响电路中其他模块以及整 个系统的性能。因此,对外部环境如工艺、电源电压和温度等变化不敏感,即基 准源的稳定性是设计中的主要指标。如果基准源的稳定性不好,那么,系统性能 也很难达到设计要求。 1964年,Hilbiber?和Widlar等人提出带隙基准的思想2][3]。从那时刻开始到 如今,带隙基准就一直是研究热点。因此,国内外对带隙基准源做了大量的研究, 其研究的进展主要集中在低温度系数[4[5][6][7]、高电源抑制比[8][9][10][11]以及 低电压[12][13][14][15]这几个方面. 目前,随着广播电视数字化的不断推进,数字电视将拥有一个十分广阔的发 展前景。而数字电视调谐器作为数字电视接收机的前置部件,在数字电视技术中 占有着非常重要的地位。由于数字电视调谐器芯片内部的VCO,混频器,锁相 环等模块都需要一个与温度、电源电压及工艺的关系小且稳定性良好的偏置电 流,因此,该芯片需要集成一个有多路输出的基准电流源,为芯片的各个模块提 供一个稳定的偏置电流。 本课题主要针对标准CMOS工艺实现了带隙基准源模块的设计,其模块包括 带隙基准电压源电路,电压-电流转换电路以及温度传感器电路。首先,对于带 隙基准电压源电路,在保证精度、温漂等各项指标的前提下,对其电源抑制比进 行了优化设计,其输出参考电压为系统其它模块提供稳定性能良好的电压偏置。 其次,对于电压-电流转换电路,它把带隙基准电压源产生的输出参考电压转换 成稳定的输出电流,为其它模块提供稳定性良好的电流偏置。最后,对于温度传 感器电路,它把输出参考电压转换成一个与温度成正比例关系的温度传感电压, 1

第一章 概述 1 第一章 概述 1.1 课题背景 随着集成电路技术的不断发展,高精度、高速度、超大规模的数字电路设计 和制造变得越来越容易,一些过去由模拟电路实现的功能模块也渐渐的由数字电 路模块替代。但是,这并不意味着模拟电路将会消失。相反,随着数字电路技术 的迅猛发展及设计系统级芯片SOC(System on Chip)技术的流行,模拟电路的重 要性进一步体现[1]。 在模拟集成电路中,广泛地用到一种重要基本单元电路——基准源,这种基 准是直流量,包括基准电压源和基准电流源。基准源既可以用作电源电压,也可 以为其他电路模块提供精确的参考电压或电流。而且,其性能的好坏直接影响到 整体电路的性能的好坏。例如,差分对的偏置电流必须根据基准产生,因为它会 影响到电路的电压增益和噪声。在模数转换器(ADC)这样的系统中,也需要基准 来确定其输入或输出的全程范围[1]。 由于基准随温度的变化和噪声等因素会严重的影响电路中其他模块以及整 个系统的性能。因此,对外部环境如工艺、电源电压和温度等变化不敏感,即基 准源的稳定性是设计中的主要指标。如果基准源的稳定性不好,那么,系统性能 也很难达到设计要求。 1964年,Hilbiber和Widlar等人提出带隙基准的思想[2][3]。从那时刻开始到 如今,带隙基准就一直是研究热点。因此,国内外对带隙基准源做了大量的研究, 其研究的进展主要集中在低温度系数[4][5][6][7]、高电源抑制比[8][9][10][11]以及 低电压[12][13][14][15]这几个方面。 目前,随着广播电视数字化的不断推进,数字电视将拥有一个十分广阔的发 展前景。而数字电视调谐器作为数字电视接收机的前置部件,在数字电视技术中 占有着非常重要的地位。由于数字电视调谐器芯片内部的VCO,混频器,锁相 环等模块都需要一个与温度、电源电压及工艺的关系小且稳定性良好的偏置电 流,因此,该芯片需要集成一个有多路输出的基准电流源,为芯片的各个模块提 供一个稳定的偏置电流。 本课题主要针对标准CMOS工艺实现了带隙基准源模块的设计,其模块包括 带隙基准电压源电路,电压-电流转换电路以及温度传感器电路。首先,对于带 隙基准电压源电路,在保证精度、温漂等各项指标的前提下,对其电源抑制比进 行了优化设计,其输出参考电压为系统其它模块提供稳定性能良好的电压偏置。 其次,对于电压-电流转换电路,它把带隙基准电压源产生的输出参考电压转换 成稳定的输出电流,为其它模块提供稳定性良好的电流偏置。最后,对于温度传 感器电路,它把输出参考电压转换成一个与温度成正比例关系的温度传感电压

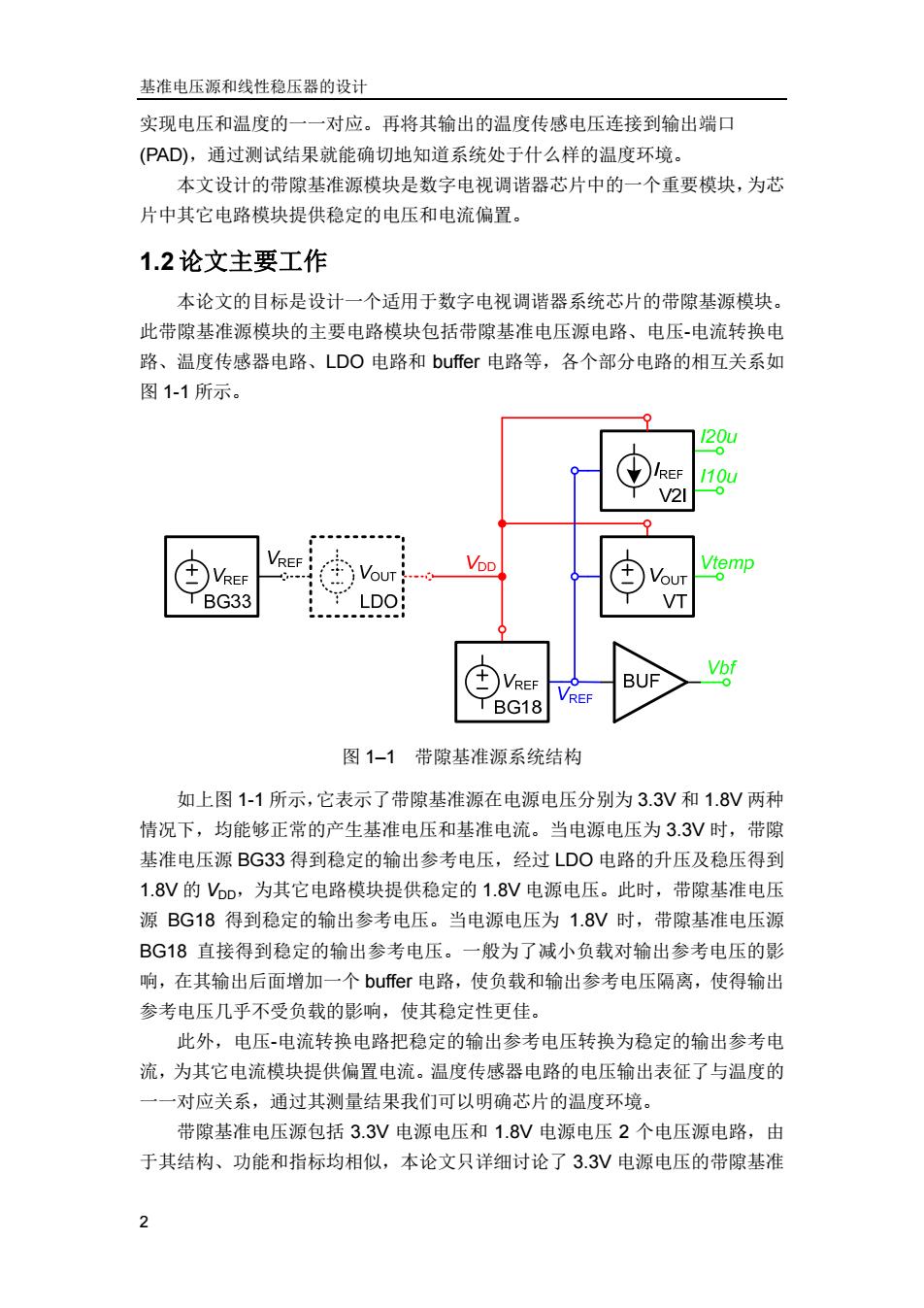

基准电压源和线性稳压器的设计 实现电压和温度的一一对应。再将其输出的温度传感电压连接到输出端口 (PAD),通过测试结果就能确切地知道系统处于什么样的温度环境。 本文设计的带隙基准源模块是数字电视调谐器芯片中的一个重要模块,为芯 片中其它电路模块提供稳定的电压和电流偏置。 1.2论文主要工作 本论文的目标是设计一个适用于数字电视调谐器系统芯片的带隙基源模块。 此带隙基准源模块的主要电路模块包括带隙基准电压源电路、电压-电流转换电 路、温度传感器电路、LDO电路和bufr电路等,各个部分电路的相互关系如 图1-1所示。 20u REF 110u 2 VREF Vtemp /OUT VOUT BG33 LDO ⊕VREF Vbf BUF TBG18 VREF 图1-1带隙基准源系统结构 如上图1-1所示,它表示了带隙基准源在电源电压分别为3.3V和1.8V两种 情况下,均能够正常的产生基准电压和基准电流。当电源电压为3.3V时,带隙 基准电压源BG33得到稳定的输出参考电压,经过LDO电路的升压及稳压得到 1.8V的VoD,为其它电路模块提供稳定的1.8V电源电压。此时,带隙基准电压 源BG18得到稳定的输出参考电压。当电源电压为1.8V时,带隙基准电压源 BG18直接得到稳定的输出参考电压。一般为了减小负载对输出参考电压的影 响,在其输出后面增加一个bufr电路,使负载和输出参考电压隔离,使得输出 参考电压几乎不受负载的影响,使其稳定性更佳。 此外,电压-电流转换电路把稳定的输出参考电压转换为稳定的输出参考电 流,为其它电流模块提供偏置电流。温度传感器电路的电压输出表征了与温度的 对应关系,通过其测量结果我们可以明确芯片的温度环境。 带隙基准电压源包括3.3V电源电压和1.8V电源电压2个电压源电路,由 于其结构、功能和指标均相似,本论文只详细讨论了3.3V电源电压的带隙基准 2

基准电压源和线性稳压器的设计 2 实现电压和温度的一一对应。再将其输出的温度传感电压连接到输出端口 (PAD),通过测试结果就能确切地知道系统处于什么样的温度环境。 本文设计的带隙基准源模块是数字电视调谐器芯片中的一个重要模块,为芯 片中其它电路模块提供稳定的电压和电流偏置。 1.2 论文主要工作 本论文的目标是设计一个适用于数字电视调谐器系统芯片的带隙基源模块。 此带隙基准源模块的主要电路模块包括带隙基准电压源电路、电压-电流转换电 路、温度传感器电路、LDO 电路和 buffer 电路等,各个部分电路的相互关系如 图 1-1 所示。 图 1–1 带隙基准源系统结构 如上图 1-1 所示,它表示了带隙基准源在电源电压分别为 3.3V 和 1.8V 两种 情况下,均能够正常的产生基准电压和基准电流。当电源电压为 3.3V 时,带隙 基准电压源 BG33 得到稳定的输出参考电压,经过 LDO 电路的升压及稳压得到 1.8V 的 VDD,为其它电路模块提供稳定的 1.8V 电源电压。此时,带隙基准电压 源 BG18 得到稳定的输出参考电压。当电源电压为 1.8V 时,带隙基准电压源 BG18 直接得到稳定的输出参考电压。一般为了减小负载对输出参考电压的影 响,在其输出后面增加一个 buffer 电路,使负载和输出参考电压隔离,使得输出 参考电压几乎不受负载的影响,使其稳定性更佳。 此外,电压-电流转换电路把稳定的输出参考电压转换为稳定的输出参考电 流,为其它电流模块提供偏置电流。温度传感器电路的电压输出表征了与温度的 一一对应关系,通过其测量结果我们可以明确芯片的温度环境。 带隙基准电压源包括 3.3V 电源电压和 1.8V 电源电压 2 个电压源电路,由 于其结构、功能和指标均相似,本论文只详细讨论了 3.3V 电源电压的带隙基准