Chapter 13 Statistical Applications in Quality Management Statistics for Managers Using Microsoft Excel

Statistics for Managers Using Microsoft Excel Chapter 13 Statistical Applications in Quality Management

Learning Objectives In this chapter,you learn: How to construct various control charts Which control charts to use for a particular type of data How to measure the capability of a process The basic themes of quality management and Deming's 14 points The basic aspects of Six Sigma Statistics for Managers Using Microsoft Excel

Statistics for Managers Using Microsoft Excel Learning Objectives In this chapter, you learn: How to construct various control charts Which control charts to use for a particular type of data How to measure the capability of a process The basic themes of quality management and Deming’s 14 points The basic aspects of Six Sigma

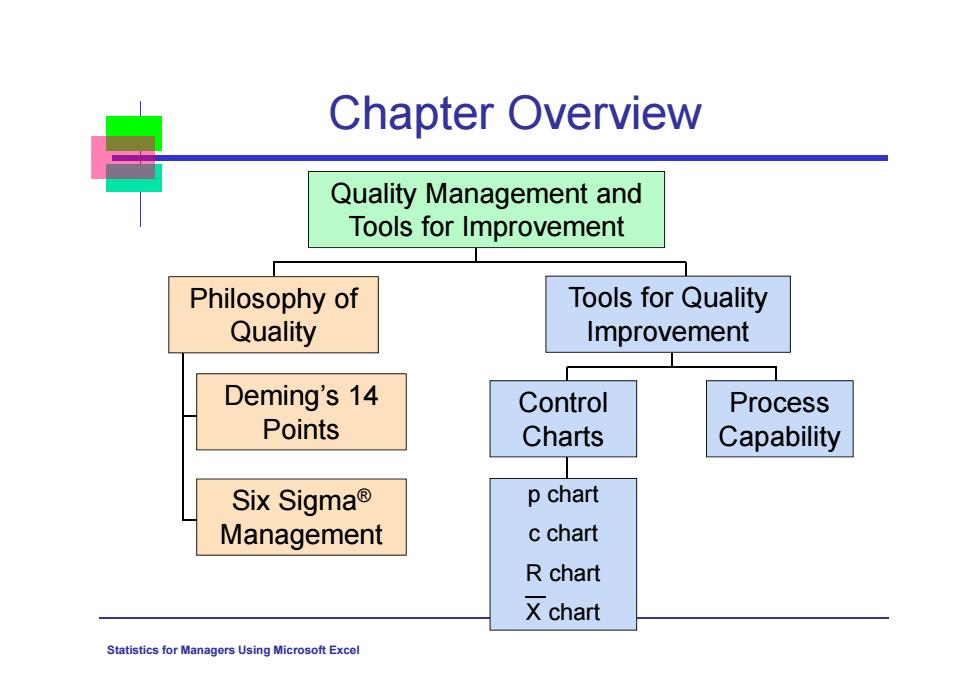

Chapter Overview Quality Management and Tools for Improvement Philosophy of Tools for Quality Quality Improvement Deming's 14 Control Process Points Charts Capability Six Sigma® p chart Management c chart R chart X chart Statistics for Managers Using Microsoft Excel

Statistics for Managers Using Microsoft Excel Chapter Overview Quality Management and Tools for Improvement Deming’s 14 Points Six Sigma® Management Process Capability Philosophy of Quality Tools for Quality Improvement Control Charts p chart c chart R chart X chart

Theory of Control Charts DCOVA A process is the value added transformation of inputs to outputs Control Charts are used to monitor variation in a measured value from a process Inherent variation refers to process variation that exists naturally.This variation can be reduced but not eliminated Statistics for Managers Using Microsoft Excel

Statistics for Managers Using Microsoft Excel Theory of Control Charts A process is the value added transformation of inputs to outputs Control Charts are used to monitor variation in a measured value from a process Inherent variation refers to process variation that exists naturally. This variation can be reduced but not eliminated DCOVA

Theory of Control Charts (continued) DCOVA Control charts indicate when changes in data are due to: Special or assignable causes Fluctuations not inherent to a process -Represents problems to be corrected Data outside control limits or trend Chance or common causes -Inherent random variations Consist of numerous small causes of random variability Statistics for Managers Using Microsoft Excel

Statistics for Managers Using Microsoft Excel Theory of Control Charts Control charts indicate when changes in data are due to: Special or assignable causes Fluctuations not inherent to a process Represents problems to be corrected Data outside control limits or trend Chance or common causes Inherent random variations Consist of numerous small causes of random variability (continued) DCOVA

Process Variation DCOVA Total Process Common Cause Special Cause Variation Variation Variation Variation is natural;inherent in the world around us No two products or service experiences are exactly the same With a fine enough gauge,all things can be seen to differ Statistics for Managers Using Microsoft Excel

Statistics for Managers Using Microsoft Excel Process Variation Total Process Variation Common Cause Variation Special Cause Variation = + Variation is natural; inherent in the world around us No two products or service experiences are exactly the same With a fine enough gauge, all things can be seen to differ DCOVA

Total Process Variation DCOVA Total Process Common Cause Special Cause X Variation Variation Variation Variation is often due to differences in: ■People ■Machines ■Materials ■Methods ■ Measurement Environment Statistics for Managers Using Microsoft Excel

Statistics for Managers Using Microsoft Excel Total Process Variation Total Process Variation Common Cause Variation Special Cause Variation = + People Machines Materials Methods Measurement Environment Variation is often due to differences in: DCOVA

Common Cause Variation DCOVA Total Process Common Cause Special Cause Variation Variation Variation Common cause variation naturally occurring and expected the result of normal variation in materials,tools,machines,operators, and the environment Statistics for Managers Using Microsoft Excel

Statistics for Managers Using Microsoft Excel Common Cause Variation Total Process Variation Common Cause Variation Special Cause Variation = + Common cause variation naturally occurring and expected the result of normal variation in materials, tools, machines, operators, and the environment DCOVA

Special Cause Variation DCOVA Total Process Common Cause Special Cause Variation Variation Variation Special cause variation abnormal or unexpected variation has an assignable cause variation beyond what is considered inherent to the process Statistics for Managers Using Microsoft Excel

Statistics for Managers Using Microsoft Excel Special Cause Variation Total Process Variation Common Cause Variation Special Cause Variation = + Special cause variation abnormal or unexpected variation has an assignable cause variation beyond what is considered inherent to the process DCOVA

Two Kinds Of Errors DCOVA Treating common cause variation as special cause variation Results in over overadjusting known as tampering Increases process variation Treating special cause variation as common cause variation Results in not taking corrective action when it should be taken Utilizing control charts greatly reduces the chance of committing either of these errors Statistics for Managers Using Microsoft Excel

Statistics for Managers Using Microsoft Excel Two Kinds Of Errors Treating common cause variation as special cause variation Results in over overadjusting known as tampering Increases process variation Treating special cause variation as common cause variation Results in not taking corrective action when it should be taken Utilizing control charts greatly reduces the chance of committing either of these errors DCOVA