双语教学思考题 说明 允许使用中英文字典 则,中文瓶用中文回答,英文厦用英文间会 3.选修小语种的同学可不做英语题,但须作附加题。 试题2005 植京(每小题05分,共计6分。甘中,中英文名洗植6顺 1 Dairy Pro ssing includes on,Standardization UHT Tr atm Refrigeration. 2.Dairy Proc essing includes include Clarification.Separation Standardization, Pasteurization UHT Treatment, Homogenization Membrane Processing,Evaporation and Dehydration,Production and Utilization of Steam and Refrigeration. 二、名词解释(每小题1.0分,共计4分。其中,中英文各2题) 1.SMP Skim milk powder(p.70) 2.WPC:whey protein concentrate(p.53) 3.buttermilk: 4.MSNF:The serum solids or milk solids-not-fat(MSNF)contain the lactose,caseins, whey proteins,minerals,and ash content of the product from which they were derived(p.86). :Traditio ally,chees p or npe a agula on an whey se cream or partly skimmed milk 48) 7.Plate heat excha consists of a stack of corrugated r in a fra T re several flow natterns that an he used Gaskets are sed to define the boundaries of the channels and to prevent leakage.The heating medium can be vacuum steam or hot water(p42). 8.Yogurt:(also spelled yogourt or yoghurt)is a semi-solid fermented milk product which originated centuries ago in Bulgaria.It's popularity has grown and is now consumed in most parts of the world.Although the consistency,flavour and aroma may vary from one region to another,the basic ingredients and manufacturing are essentially consistent(p.75): 9.LA:Lactob acidophilus(p.77)) 10. d ba 简述题(每小题7.0分,共计42分。其中,中英文各3题) 1.How to Separate the cream from milk?(p.39) Centrifuges car used to separate the crea rom the skim milk.The centrifug 120 discs stacke 08 0 degree e and separate cs has vertically aligne n hol out the milk is introduced

双语教学思考题 说明: 1. 允许使用中英文字典。 2. 原则上,中文题用中文回答,英文题用英文回答。 3. 选修小语种的同学可不做英语题,但须作附加题。 试题 2005 一、填空(每小题 0.5 分,共计 6 分。其中,中英文各选填 6 题) 1. Dairy Processing includes include Clarification, Separation, Standardization, Pasteurization, UHT Treatment , Homogenization, Membrane Processing, Evaporation and Dehydration, Production and Utilization of Steam and Refrigeration. 2. Dairy Processing includes include Clarification, Separation, Standardization, Pasteurization, UHT Treatment , Homogenization, Membrane Processing, Evaporation and Dehydration, Production and Utilization of Steam and Refrigeration. 二、名词解释(每小题 1.0 分,共计 4 分。其中,中英文各 2 题) 1. SMP :Skim milk powder (p.70) 2. WPC: whey protein concentrate(p.53) 3. buttermilk: 4. MSNF: The serum solids or milk solids-not-fat (MSNF) contain the lactose, caseins, whey proteins,minerals, and ash content of the product from which they were derived(p.86). 5. Cheese :Traditionally, cheese was made as a way of preserving the nutrients of milk. In a simple definition, cheese is the fresh or ripened product obtained after coagulation and whey separation of milk, cream or partly skimmed milk, buttermilk or a mixture of these products. (p.72) 6. UHT: ultra-high temperature(p.48) 7. Plate heat exchanger. This piece of equipment consists of a stack of corrugated stainless steel plates clamped together in a frame. There are several flow patterns that can be used. Gaskets are used to define the boundaries of the channels and to prevent leakage. The heating medium can be vacuum steam or hot water(p42). 8. Yogurt: (also spelled yogourt or yoghurt) is a semi-solid fermented milk product which originated centuries ago in Bulgaria. It's popularity has grown and is now consumed in most parts of the world. Although the consistency, flavour and aroma may vary from one region to another, the basic ingredients and manufacturing are essentially consistent(p.75): 9. LA: Lactobacillus acidophilus(p.77) 10. LAB: lactic acid bacteria (p.73) 三、简述题(每小题 7.0 分,共计 42 分。其中,中英文各 3 题) 1. How to Separate the cream from milk?(p.39) Centrifuges can be used to separate the cream from the skim milk. The centrifuge consists of up to 120 discs stacked together at a 45 to 60 degree angle and separated by a 0.4 to 2.0 mm gap or separation channel. Milk is introduced at the outer edge of the disc stack. The stack of discs has vertically aligned distribution holes into which the milk is introduced

Under the influence of centrifugal force the fat globules(cream),which are less dense than the skim milk,move inwards through the separation channels toward the axis of rotation.The skim milk will move outwards and leaves through a separate outlet. 2.How to standardize the milk?(p.40) The strem of skmnd cremecomndospfied fat content.This an be don etely cl d. dis em ou r c hing fa sare dis di come basic standardizatio nass pro ride the nce and Pearson sa approach can be viewed he 3.What is the Stoke's Law ???(p.39)? Centrifugation is based on Stoke's Law.The particle sedimentation velocity increases with: ·increasing diameter increasing difference in density between the two phases decreasing viscosity of the continuous phase If raw milk were a wed to stand the fat n a phenomena called erean mg on n.In of milk fat from the skim 4 What is the Continuous method of Pasteurization of milk?(p.42) Continuous process method has several advantage over the vat method the mos important being time and energy saving.For most continuous rocessing a high temperature short time (HTST)pasteurizer is used.The heat treatment is accomplished using a plate heat exchanger.This piece of equipment consists of a stack of corrugated stainless steel plates clamped together in a frame.There are several flow patterns that can be used.Gaskets are used to define the boundaries of the channels and to prevent leakage.The heating medium can be vacuum steam or hot water. 5.What is the Batch method of Pasteurization of milk?(p.42) vat pasteurizer whic I the vat the mik isheated and hh riod while being T k he ed in t ed hng he holdi o i

Under the influence of centrifugal force the fat globules (cream), which are less dense than the skim milk, move inwards through the separation channels toward the axis of rotation. The skim milk will move outwards and leaves through a separate outlet. 2. How to standardize the milk?(p.40) The streams of skim and cream after separation must be recombined to a specified fat content. This can be done by adjusting the throttling valve of the cream outlet; if the valve is completely closed, all milk will be discharged through the skim milk outlet. As the valve is progressively opened, larger amounts of cream with diminishing fat contents are discharged from the cream outlet. With direct standardization the cream and skim are automatically remixed at the separator to provide the desired fat content. Some basic standardization problems including mass balance and Pearson square approach can be viewed here. 3. What is the Stoke's Law ???(p.39)? Centrifugation is based on Stoke's Law. The particle sedimentation velocity increases with: • increasing diameter • increasing difference in density between the two phases • decreasing viscosity of the continuous phase If raw milk were allowed to stand, the fat globules would begin to rise to the surface in a phenomena called creaming. Raw milk in a rotating container also has centrifugal forces acting on it. This allows rapid separation of milk fat from the skim milk portion and removal of solid impurities from the milk. 4 What is the Continuous method of Pasteurization of milk?(p.42) Continuous process method has several advantages over the vat method, the most important being time and energy saving. For most continuous processing, a high temperature short time (HTST) pasteurizer is used. The heat treatment is accomplished using a plate heat exchanger. This piece of equipment consists of a stack of corrugated stainless steel plates clamped together in a frame. There are several flow patterns that can be used. Gaskets are used to define the boundaries of the channels and to prevent leakage. The heating medium can be vacuum steam or hot water. 5. What is the Batch method of Pasteurization of milk?(p.42) The batch method uses a vat pasteurizer which consists of a jacketed vat surrounded by either circulating water, steam or heating coils of water or steam. In the vat the milk is heated and held throughout the holding period while being agitated. The milk may be cooled in the vat or removed hot after the holding time is completed for every particle. As a modification, the milk may be partially heated in

tubular or plate heater before entering the vat.This method has very little use for milk but some use for milk by-products(e.g.creams,chocolate)and special batches.The vat is used extensivly in the ice cream industry for mix quality reasons other than microbial reasons. 6.What is Recombined Milk?(p.67) Beverage milks can also be prepared by recombining skim milk pow er and butte done in countries where th Is not eno ugh mil b ncept te t per outter into th the liqu 0 id thr In n-dairy fat s also be used.The mbined mill duct is the d ho ized and as in r mlar milk r oduction.The final composition is similar to that of whole milk,app oximately 9%milk solids. ot-fat and either 2%or 34%fat.The water source must be of excellent quality.The milk powder used for recombining must be of high quality and good flavour.Care must be taken to ensure adequate blending of the ingredients to prevent aggregation or lumping of the powder.Its dispersal in water is the key to success. 四、论述题 1.How to produce Stirred style yogurt(p.76) The milk is clarified and separated into cream and skim milk,then standardized to acheive the des with a powder funneens are then blende nded together in a mix tank innel and n agitat system mixture is the for Thes much pasteurizatior are necessary to acheive the ollowing more severe a relatively sterile ondusiv vir 4 nd c late whe y proteins to The mix is then homogenized using high pressures of 2000-2500 psi.Besides thoroughly mixing the stabilizers and other ingredients homogenization also prevents creaming and wheying off during incubation and storage.Stability,consistency and body are enhanced by homogenization.Once the homogenized mix has cooled to an optimum growth temperature,the yogurt starter culture is added A ratio of 1:1,ST to LB,inoculation is added to the jacketed fermentation tank.A temperature of 43 C is maintained for 4-6 h under quiescent(no agitation)conditions two micoorganism LB C).I the jac atable a arefully monit nt the s vith e ed The lod and s pe atures (5 to slow down ohysical chemical and microbiolo

tubular or plate heater before entering the vat. This method has very little use for milk but some use for milk by-products (e.g. creams, chocolate) and special batches. The vat is used extensivly in the ice cream industry for mix quality reasons other than microbial reasons. 6. What is Recombined Milk?(p.67) Beverage milks can also be prepared by recombining skim milk powder and butter with water. This is often done in countries where there is not enough milk production to meet the demand for beverage milk consumption. The concept is simple. Skim milk powder is dispersed in water and allowed to hydrate. Butter is then emulsified into this mixture by either blending melted butter into the liquid mixture while hot, or by dispersing solid butter into the liquid through a high shear blender device. In some cases, a non-dairy fat source may also be used. The recombined milk product is then pasteurized, homogenized and packaged as in regular milk production. The final composition is similar to that of whole milk, approximately 9% milk solids-not-fat, and either 2% or 3.4% fat. The water source must be of excellent quality. The milk powder used for recombining must be of high quality and good flavour. Care must be taken to ensure adequate blending of the ingredients to prevent aggregation or lumping of the powder. Its dispersal in water is the key to success. 四、论述题 1. How to produce Stirred style yogurt(p.76) The milk is clarified and separated into cream and skim milk, then standardized to acheive the desired fat content. The various ingredients are then blended together in a mix tank equipped with a powder funnel and an agitation system. The mixture is then pasteurized using a continuous plate heat exchanger for 30 min at 85° C or 10 min at 95° C. These heat treatments, which are much more severe than fluid milk pasteurization, are necessary to acheive the following: • produce a relatively sterile and condusive environment for the starter culture • denature and coagulate whey proteins to enhance the viscosity and texture The mix is then homogenized using high pressures of 2000-2500 psi. Besides thoroughly mixing the stabilizers and other ingredients, homogenization also prevents creaming and wheying off during incubation and storage. Stability, consistency and body are enhanced by homogenization. Once the homogenized mix has cooled to an optimum growth temperature, the yogurt starter culture is added. A ratio of 1:1, ST to LB, inoculation is added to the jacketed fermentation tank. A temperature of 43° C is maintained for 4-6 h under quiescent (no agitation) conditions. This temperature is a compromise between the optimums for the two micoorganisms (ST 39° C; LB 45° C). The titratable acidity is carefully monitored until the TA is 0.85 to 0.90%. At this time the jacket is replaced with cool water and agitation begins, both of which stop the fermentation. The coagulated product is cooled to 5-22° C, depending on the product. Fruit and flavour may be incorporated at this time, then packaged. The product is now cooled and stored at refrigeration temperatures (5° C) to slow down the physical, chemical and microbiological degradation

2.How can raw milk be homogenized ?(p.52) Milk is an oil-in-water emulsion,with the fat globules dispersed in a continuous skimmilk phase.If raw milk were left to stand,however,the fat would rise and form a cream layer.Homogenization is a mechanical treatment of the fat globules in milk brought about by passing milk under high pressure through a tiny orifice,which results I a decrease in the average diameter and an increase in number and surface area, fat globul rom a practical view s a much at g abilit m the ed of rise to milar for the 111 t the na)and a density of th (hringing them close r to the continuous phase)oweing to the adso f a n ein membrane In addition.heat p cluster fat globules causing them to rise. 五、英翻汉(20分) 1.Milk Powder Milk used in the production of milk powders is first clarified,standardized and then given a heat treatment.This heat treatment is usually more severe than that required for pasteurization.Besides destroying all the pathogenic and most of the spoilage microorganisms.it also inactivates the enzyme lipase which could cause lipolysis during storage The milk is then evaporated prior to drying for the following reasons: .: less occluded air anc 。less to larger P energy requiredt er by evaporation;more economical ay be anplied to ded sed method for the free fat co Spray drying is the milk powders After dry the must be packaged in containers able to provide protection from moisture,air,light,etc.Whole milk powder can then be stored for long periods(up to about 6 months)of time at ambient temperatures. Skim milk powder(SMP)processing is similar to that described above except for the following points: contains less milkfat(0.05-0.10%) 3 heat treatment prior to evaporation can be more or less severe homogeniz ot require maximum s shelf life extenc to approximately 3 years at SMP addition to pasteurizatic This duct is sed in the e bake industry.chocolate and other foods wher e a high degr mired Instant milk powder is produced by

2. How can raw milk be homogenized ?(p.52) Milk is an oil-in-water emulsion, with the fat globules dispersed in a continuous skimmilk phase. If raw milk were left to stand, however, the fat would rise and form a cream layer. Homogenization is a mechanical treatment of the fat globules in milk brought about by passing milk under high pressure through a tiny orifice, which results in a decrease in the average diameter and an increase in number and surface area, of the fat globules. The net result, from a practical view, is a much reduced tendency for creaming of fat globules. Three factors contribute to this enhanced stability of homogenized milk: a decrease in the mean diameter of the fat globules (a factor in Stokes Law), a decrease in the size distribution of the fat globules (causing the speed of rise to be similar for the majority of globules such that they don't tend to cluster during creaming), and an increase in density of the globules (bringing them closer to the continuous phase) oweing to the adsorption of a protein membrane. In addition, heat pasteurization breaks down the cryo-globulin complex, which tends to cluster fat globules causing them to rise. 五、英翻汉(20 分) 1. Milk Powder Milk used in the production of milk powders is first clarified, standardized and then given a heat treatment. This heat treatment is usually more severe than that required for pasteurization. Besides destroying all the pathogenic and most of the spoilage microorganisms, it also inactivates the enzyme lipase which could cause lipolysis during storage. The milk is then evaporated prior to drying for the following reasons: • less occluded air and longer shelf life for the powder • viscosity increase leads to larger powder particles • less energy required to remove part of water by evaporation; more economical Homogenization may be applied to decrease the free fat content. Spray drying is the most used method for producing milk powders. After drying, the powder must be packaged in containers able to provide protection from moisture, air, light, etc. Whole milk powder can then be stored for long periods (up to about 6 months) of time at ambient temperatures. Skim milk powder (SMP) processing is similar to that described above except for the following points: 1. contains less milkfat (0.05-0.10%) 2. heat treatment prior to evaporation can be more or less severe 3. homogenization not required 4. maximum shelf life extended to approximately 3 years Low-heat SMP is given a pasteurization heat treatment and is used in the production of cheese, baby foods etc. High-heat SMP requires a more intense heat treatment in addition to pasteurization. This product is used in the bakery industry, chocolate industry, and other foods where a high degree of protein denaturation is required. Instant milk powder is produced by partially rehydrating the dried milk powder

particles causing them to become sticky and agglomerate.The water is then removed by drying resulting in an increased amount of air incorporated between the powder particles. 2.Cream(p.66) During the separation of whole milk,two streams are produced:the fat-depleted stream, whic the beverage milks as de ve or skim milk for n and pos Ior su rear cre d u the 、1 th y have high tail sale ally in the 15 500/fat A be oduced fr of milk se s This oduct has a fat co 800 fat hut it r as an mulsion (the fat in the form of and theskim mikis the continuous phase of the emulsion).unlike butter which also has a fat content of 80%but which has been churned so that the fat occupies the continuous phase and the skim milk is dispersed throughout in the form of tiny droplets (a water-in-oil emulsion). For retail cream products,the fat is normally standardized to 35%(heavy cream for bcPpehc%ocret6ceanmnccmtieorcereab Higher fat creams have alsc ale,a produc 1 as ole crean content o pac ens ea obul and This ha a loss oduct to d as a fat s(10% r180%)ca nized han whole milk 3 Che se Traditionally,chees was made as a way of preserving the nutrients of milk In a simple definition.cheese is the fresh or ripened roduct obtained after or a mixture of these products.It is essentially the product of selective concentration of milk.Thousands of varieties of cheeses have evolved that are characteristic of various regions of the world Some common cheesemaking steps will be outlined here.Also included is a docu Ma and inf ng chare hel Treatment of milk ·Additives Inoculation and Milk Ripening 。Coagulation o enzyme o acid heat-aci

particles causing them to become sticky and agglomerate. The water is then removed by drying resulting in an increased amount of air incorporated between the powder particles. 2. Cream(p.66) During the separation of whole milk, two streams are produced: the fat-depleted stream, which produces the beverage milks as described above or skim milk for evaporation and possibly for subsequent drying, and the fat-rich stream, the cream. This usually comes off the separator with fat contents in the 35-45% range. Cream is used for further processing in the dairy industry for the production of ice cream or butter, or can be sold to other food processing industries. These industrial products normally have higher fat contents than creams for retail sale, normally in the range of 45-50% fat. A product known as "plastic" cream can be produced from certain types of milk separators. This product has a fat content approaching 80% fat, but it remains as an oil-in-water emulsion (the fat is still in the form of globules and the skim milk is the continuous phase of the emulsion), unlike butter which also has a fat content of 80% but which has been churned so that the fat occupies the continuous phase and the skim milk is dispersed throughout in the form of tiny droplets (a water-in-oil emulsion). For retail cream products, the fat is normally standardized to 35% (heavy cream for whipping), 18% or 10% (cream for coffee or cereal). Higher fat creams have also been produced for retail sale, a product known as double cream has a fat content of 55% and is quite thick. Creams for packaging and sale in the retail market must be pasteurized to ensure freedom from pathogenic bacteria. Whipping cream is not normally homogenized, as the high fat content will lead to extensive fat globule aggregation and clustering, which leads to excessive viscosity and a loss of whipping ability. This phenomena has been used, however, to produce a spoonable cream product to be used as a dessert topping. Lower fat creams (10% or 18%) can be homogenized, usually at lower pressure than whole milk. 3. Cheese:Traditionally, cheese was made as a way of preserving the nutrients of milk. In a simple definition, cheese is the fresh or ripened product obtained after coagulation and whey separation of milk, cream or partly skimmed milk, buttermilk or a mixture of these products. It is essentially the product of selective concentration of milk. Thousands of varieties of cheeses have evolved that are characteristic of various regions of the world. Some common cheesemaking steps will be outlined here. Also included is a document entitled Making Cheese at Home, which includes some helpful references, several simple cheese making procedures and information about sourcing cheese making supplies. • Treatment of Milk • Additives • Inoculation and Milk Ripening • Coagulation o enzyme o acid o heat-acid • Curd Treatment • Cheese Ripening

Treatment of Milk for Cheesemaking Like most dairy products,cheesemilk must first be clarified,separated and standardized.The milk may then be subjected to a sub-pasteurization treatment of 63-65 C for 15 to 16 sec.This thermization treatment results in a reduction of high initial bacteria counts before storage.It must be followed by proper pasteurization While HTST mment ofbasteurization (2C for sees often used.an alternative he ay also be use This less severe heat treatment noug na d a better final by preservin ust be stored for days prior to sale,which is similar to the regula Homogenization is not usually done for most cheesemilk it disrunts the fat globules and increases the fat surface area where casein particles adsorb.This reults in a soft. weak curd at renneting and increased hydrolytic rancidity. Additives The following may all be added to the cheese milk ·Calcium choride 。nitrates colour hydrogen peroxide lipases Calcium choride is added to replace calcium redistributed during pasteurization Milk coagulati by ren et during eese ma an optimum ba ance and both so ng requires e ca um phosphate sa Because e forms ostored duri g24-48b mkers can' vait that l CaC12 is added to resto ionic calcium The calcium assists in coagulation and reduces the amount of rennet required. Sodium or potassium nitrate is added to the milk to control the undesirable effects of Clostridium tyrobutyricum in chee es such as Edam,Gouda,and Swiss Because milk colour varies from season to season.colour may added to standardize the colour of the cheese throughout the year.Annato,Beta-carotene,and paprika are used. The addition of hydrogen peroxide is sometimes used as an alternative treatment for full pateurization. Lipases,normally present in raw milk,are inactivated during pasteurization.The addition of kid goat lipases are common to ensure proper flavour development through fat hydrolysis

Treatment of Milk for Cheesemaking Like most dairy products, cheesemilk must first be clarified, separated and standardized. The milk may then be subjected to a sub-pasteurization treatment of 63-65° C for 15 to 16 sec. This thermization treatment results in a reduction of high initial bacteria counts before storage. It must be followed by proper pasteurization. While HTST pasteurization (72° C for 16 sec) is often used, an alternative heat treatment of 60° C for 16 sec may also be used. This less severe heat treatment is thought to result in a better final flavour cheese by preserving some of the natural flora. If used, the cheese must be stored for 60 days prior to sale, which is similar to the regulations for raw milk cheese. Homogenization is not usually done for most cheesemilk. It disrupts the fat globules and increases the fat surface area where casein particles adsorb. This reults in a soft, weak curd at renneting and increased hydrolytic rancidity. Additives The following may all be added to the cheese milk: • Calcium choride • nitrates • colour • hydrogen peroxide • lipases Calcium choride is added to replace calcium redistributed during pasteurization. Milk coagulation by rennet during cheese making requires an optimum balance among ionic calcium and both soluble insoluble calcium phosphate salts. Because calcium phosphates have reverse solubility with respect to temperature, the heat treatment from pasteurization causes the equilibrium to shift towards insoluble forms and depletes both soluble calcium phosphates and ionic calcium. Near normal equilibrium is restored during 24 - 48 hours of cold storage, but cheese makers can't wait that long, so CaCl2 is added to restore ionic calcium and improve rennetability. The calcium assists in coagulation and reduces the amount of rennet required. Sodium or potassium nitrate is added to the milk to control the undesirable effects of Clostridium tyrobutyricum in cheeses such as Edam, Gouda, and Swiss. Because milk colour varies from season to season, colour may added to standardize the colour of the cheese throughout the year. Annato, Beta-carotene, and paprika are used. The addition of hydrogen peroxide is sometimes used as an alternative treatment for full pateurization. Lipases, normally present in raw milk, are inactivated during pasteurization. The addition of kid goat lipases are common to ensure proper flavour development through fat hydrolysis

Inoculation and Milk Ripening The basis of cheesemaking relies on the fermentation of lactose by lactic acid bacteria(LAB).LAB produce lactic acid which lowers the pH and in turn assists goegeo2e2aeR2TABopa also produce growth fa ors wh ich encourages the growth of non- 3,and and prot essary ng ct and starter cultures ca ogy section After innoculation with the starter culture the milk is held for 45 to 60 min at 25 to 30°Cto sure the bacteria are active ing and have de veloped acidity.This Milk Coagulation Coagulation is essentially the formation of a gel by destabilizing the casein micelles causing them to aggregate and form a network which partially immobilizes the water and traps the fat globules in the newly formed matrix.This may be accomplished with: atment heat-acid treatmen Enzymes Chymosin,or rennet,is most often used for enzyme coagulation Acid Tre of the milk results in casein micelle destabili an renr curd e to the los s of calcium on can be ch ed n with the ure,or art with the che and Cr d coagulate cheeses may ine阴 ottag Heat-Acid Treatment Heat cause on of t .With the whey s.The denatured proteins then interact -789 lation 90%of p ed.E mp made by this method include Paneer.Ricotta and Queso Blanco. Curd Treatment After the milk has gel has been allowed to reach the desired firmness,it is carefully cut into small pieces with knife blades or wires.This shortens the distance and increases the available area for whey to be released.The curd pieces immediately begin to shrink and expel the greenish liquid called whey.This syneresis process is further driven by a cooking stage.The increase in temperature causes the protein matrix to shrink due to increased hydrophobic interactions,and also increases the rate

Inoculation and Milk Ripening The basis of cheesemaking relies on the fermentation of lactose by lactic acid bacteria (LAB). LAB produce lactic acid which lowers the pH and in turn assists coagulation, promotes syneresis, helps prevent spoilage and pathogenic bacteria from growing, contributes to cheese texture, flavour and keeping quality. LAB also produce growth factors which encourages the growth of non-starter organisms, and provides lipases and proteases necessary for flavour development during curing. Further information on LAB and starter cultures can be found in the microbiology section. After innoculation with the starter culture, the milk is held for 45 to 60 min at 25 to 30° C to ensure the bacteria are active, growing and have developed acidity. This stage is called ripening the milk and is done prior to renneting. Milk Coagulation Coagulation is essentially the formation of a gel by destabilizing the casein micelles causing them to aggregate and form a network which partially immobilizes the water and traps the fat globules in the newly formed matrix. This may be accomplished with: • enzymes • acid treatment • heat-acid treatment Enzymes Chymosin, or rennet, is most often used for enzyme coagulation. Acid Treatment Lowering the pH of the milk results in casein micelle destabilization or aggregation. Acid curd is more fragile than rennet curd due to the loss of calcium. Acid coagulation can be achieved naturally with the starter culture, or artificially with the addition of gluconodeltalactone. Acid coagulated fresh cheeses may include Cottage cheese, Quark, and Cream cheese. Heat-Acid Treatment Heat causes denaturation of the whey proteins. The denatured proteins then interact with the caseins. With the addition of acid, the caseins precipitate with the whey proteins. In rennet coagulation, only 76-78% of the protein is recovered, while in heat-acid coagulation, 90% of protein can be recovered. Examples of cheeses made by this method include Paneer, Ricotta and Queso Blanco. Curd Treatment After the milk has gel has been allowed to reach the desired firmness, it is carefully cut into small pieces with knife blades or wires. This shortens the distance and increases the available area for whey to be released. The curd pieces immediately begin to shrink and expel the greenish liquid called whey. This syneresis process is further driven by a cooking stage. The increase in temperature causes the protein matrix to shrink due to increased hydrophobic interactions, and also increases the rate

of fermentation of lactose to lactic acid.The increased acidity also contributes to shrinkage of the curd particles.The final moisture content is dependant on the time and temperature of the cook stage.This is important to monitor carefully because the final moisture content of the curd determines the residual amount of fermentable lactose and thus the final pH of the cheese after curing. When the curds have reached the desired moisture and acidity they are separated ained by gravity.Th eese var oy. Brick es the d conte ose conten idity,decrease s open Curd handling from this point on is very specific for each cheese variety.Salting may be achieved through brine as with Gouda.surface salt as with Feta.or vat salt as with Cheddar.To acheive the characteritics of Cheddar,a cheddaring stage(curd manipulation),milling(cut into shreds),and pressing at high pressure are crucial. Cheese ripening Except for fresh cheese,the curd is ripened,or matured,at various temperatures and times until the characteristic flavour,body and texture profile is achieved.During ripening.degradation of lactose,proteins and fat are carried out by ripening agents The ripening agents in cheese are added moulds or yeasts environmental contaminants 4.Whipped Cream Structure The structure of whipped cream is very similar to the fat and air structure that exists in ice cream.Cream is an emulsion with a fat content of 35-40%.When you whip a bowl of heavy cream,the agitation and the air bubbles that are added cause the fat globules to begin to partially coalesce in chains and clusters and adsorb to and spread around the air bubbles As the fat partially coalesces.it causes one fat-stabilized air bubble to be linked to the next,and so on ne whipp cream soon starts to become stif and ry appea es on a sm extu Thi ng and 0n0 ob: ing th a re trapped】 e spaces aroun d air bubble tial whip is very temperat dep th and la lobule ble of st ed h ther into chains and clusters

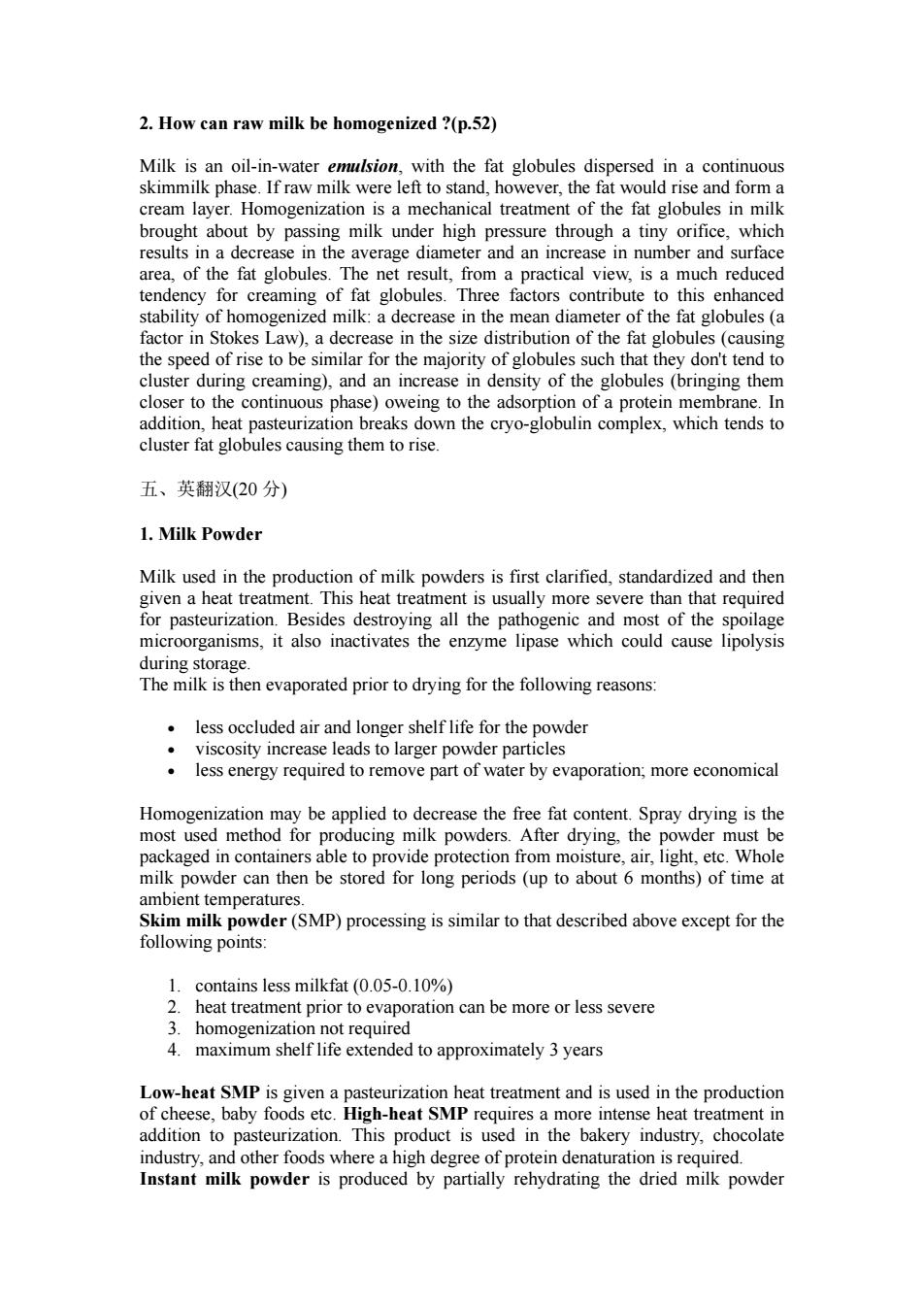

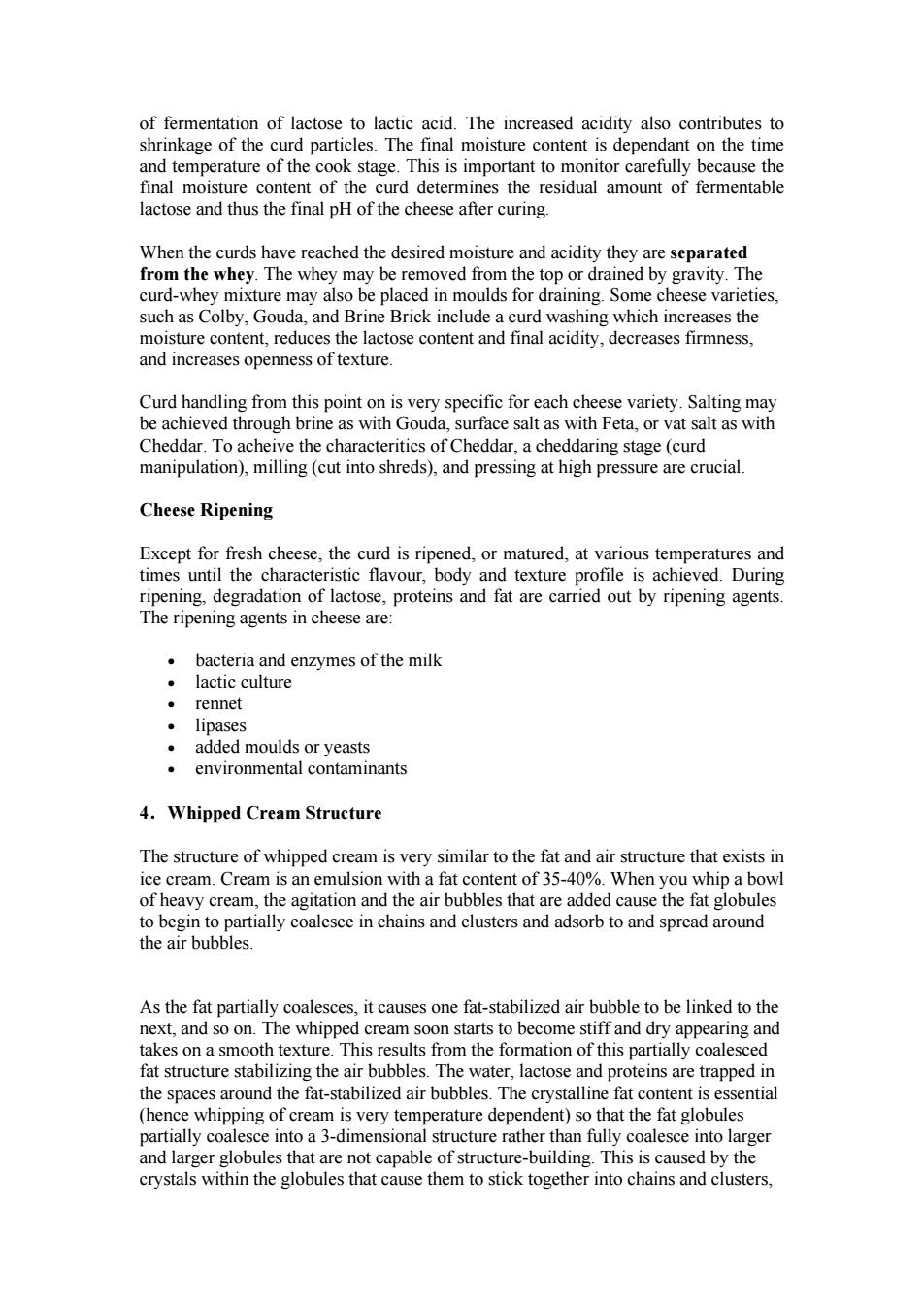

of fermentation of lactose to lactic acid. The increased acidity also contributes to shrinkage of the curd particles. The final moisture content is dependant on the time and temperature of the cook stage. This is important to monitor carefully because the final moisture content of the curd determines the residual amount of fermentable lactose and thus the final pH of the cheese after curing. When the curds have reached the desired moisture and acidity they are separated from the whey. The whey may be removed from the top or drained by gravity. The curd-whey mixture may also be placed in moulds for draining. Some cheese varieties, such as Colby, Gouda, and Brine Brick include a curd washing which increases the moisture content, reduces the lactose content and final acidity, decreases firmness, and increases openness of texture. Curd handling from this point on is very specific for each cheese variety. Salting may be achieved through brine as with Gouda, surface salt as with Feta, or vat salt as with Cheddar. To acheive the characteritics of Cheddar, a cheddaring stage (curd manipulation), milling (cut into shreds), and pressing at high pressure are crucial. Cheese Ripening Except for fresh cheese, the curd is ripened, or matured, at various temperatures and times until the characteristic flavour, body and texture profile is achieved. During ripening, degradation of lactose, proteins and fat are carried out by ripening agents. The ripening agents in cheese are: • bacteria and enzymes of the milk • lactic culture • rennet • lipases • added moulds or yeasts • environmental contaminants 4.Whipped Cream Structure The structure of whipped cream is very similar to the fat and air structure that exists in ice cream. Cream is an emulsion with a fat content of 35-40%. When you whip a bowl of heavy cream, the agitation and the air bubbles that are added cause the fat globules to begin to partially coalesce in chains and clusters and adsorb to and spread around the air bubbles. As the fat partially coalesces, it causes one fat-stabilized air bubble to be linked to the next, and so on. The whipped cream soon starts to become stiff and dry appearing and takes on a smooth texture. This results from the formation of this partially coalesced fat structure stabilizing the air bubbles. The water, lactose and proteins are trapped in the spaces around the fat-stabilized air bubbles. The crystalline fat content is essential (hence whipping of cream is very temperature dependent) so that the fat globules partially coalesce into a 3-dimensional structure rather than fully coalesce into larger and larger globules that are not capable of structure-building. This is caused by the crystals within the globules that cause them to stick together into chains and clusters

but still retain the individual identity of the globules.Please see a further description of this process for details.If whipped cream is whipped too far,the fat will begin to churn and butter particles will form. Below are scanning electron micrographs image of whipped cream.If you compare the schematics above with the "real thing"below,you should be able to fully understand whipped cream structure. The structure of whipped cream as determined by scanning electron microscopy.A. Overview showing the relative size and prevalence of air bubbles(a)and fat globules (f);bar 30 um.B.Internal structure of the air bubble,showing the layer of partially coalesced fat which has stabilized the bubble;bar =5 um.C.Details of the partially coalesced fat layer,showing the interaction of the individual fat globules.Bar =3 um

but still retain the individual identity of the globules. Please see a further description of this process for details. If whipped cream is whipped too far, the fat will begin to churn and butter particles will form. Below are scanning electron micrographs image of whipped cream. If you compare the schematics above with the "real thing" below, you should be able to fully understand whipped cream structure. The structure of whipped cream as determined by scanning electron microscopy. A. Overview showing the relative size and prevalence of air bubbles (a) and fat globules (f); bar = 30 um. B. Internal structure of the air bubble, showing the layer of partially coalesced fat which has stabilized the bubble; bar = 5 um. C. Details of the partially coalesced fat layer, showing the interaction of the individual fat globules. Bar = 3 um